Best Carbon Black Dispersion Tester Machine Manufacturer in the USA

Introduction

In rubber and plastic products, carbon black is an essential product. It strengthens materials, helps with toughness, and in many cable compounds it also supports electrical behavior and heat and chemical resistance. But it only works properly when it is mixed well. If carbon black stays in clumps, the product can end up with weak zones, inconsistent properties, or early failure in service. That is why many USA labs and factories use a Carbon Black Dispersion Tester Machine to check mixing quality before they approve a batch.

What Is a Carbon Black Dispersion Tester?

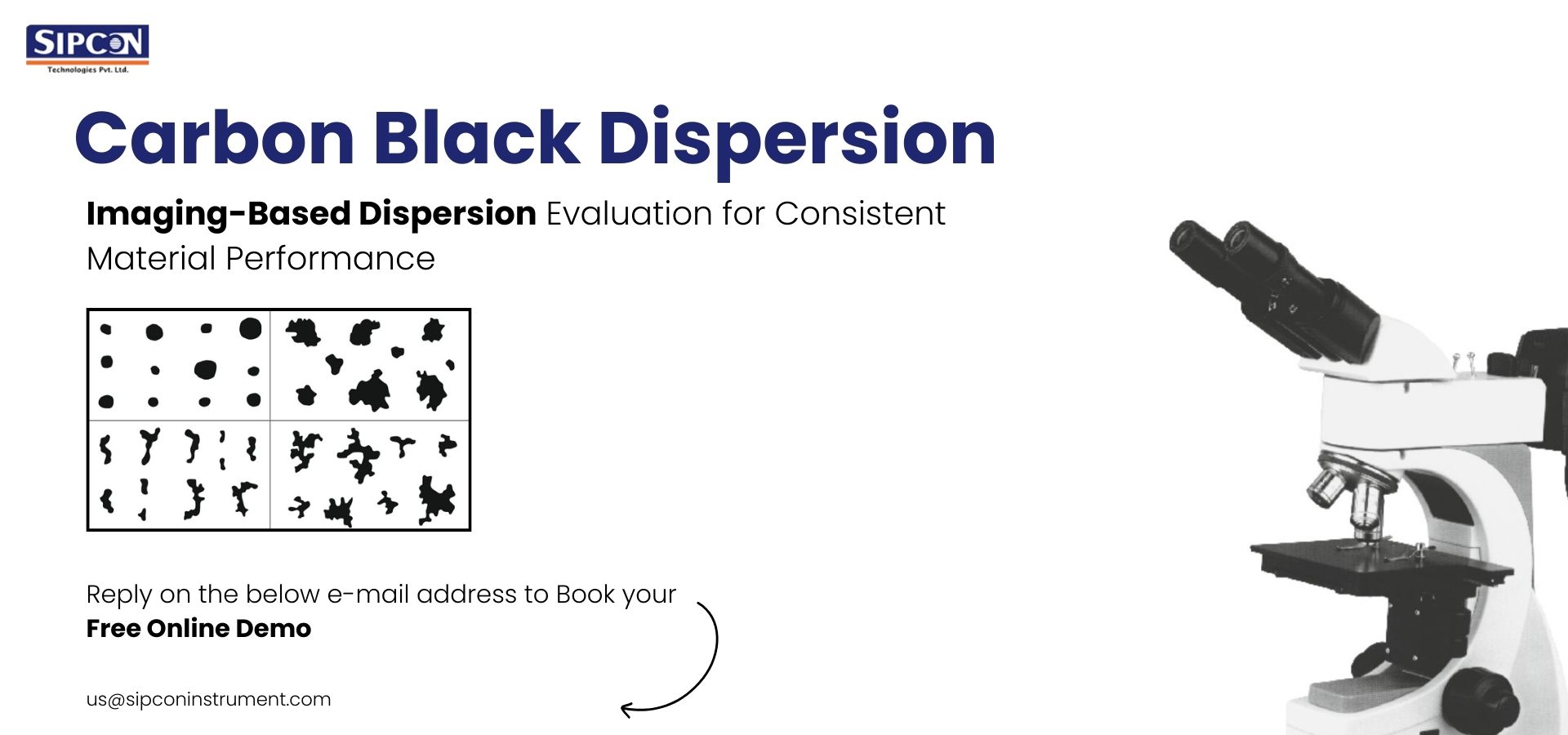

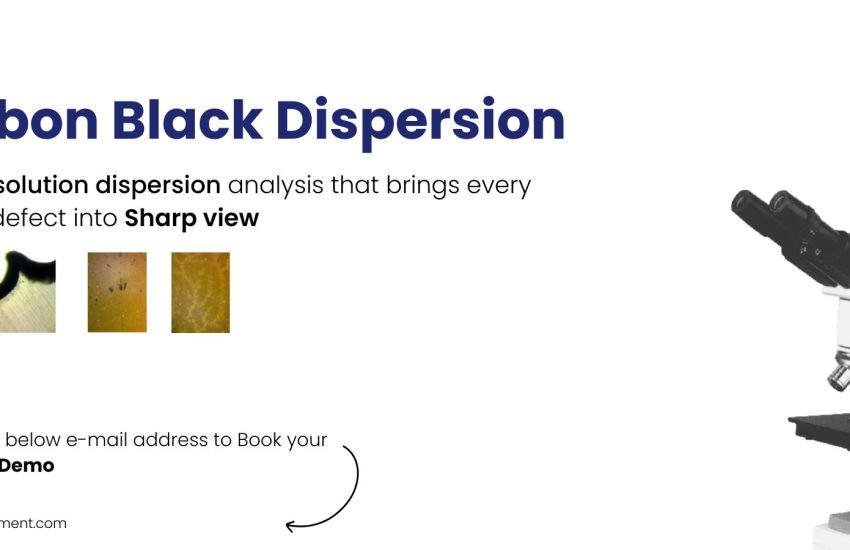

A carbon black dispersion tester is usually a microscope-based system that lets you “see” how carbon black particles are distributed inside a polymer or rubber sample. In a well-dispersed sample, the particles look small and evenly spread, while a poorly dispersed sample shows larger clusters. Modern systems pair optics with digital imaging so results can be captured, rated, and shared in reports.

Importance of Carbon Black Dispersion Testing in USA Industries

Dispersion testing is widely used as a quality control step because it connects directly with performance and process stability. ISO 11345:2006 describes rapid, comparative methods for assessing macro-dispersion of carbon black (and carbon black plus silica) in rubber, using ratings relative to standard reference photographs on a 1 to 10 scale. For cable manufacturing and similar polymer applications, Sipcon notes that microscopy is a direct way to evaluate dispersion and spot clusters that signal poor mixing.

Product and Functionality

When people search “best carbon black dispersion tester machine manufacturer in the USA,” they often want two things at once: a proven instrument design and dependable USA-side support for training, spares, and service. In the automated optical category, Alpha Technologies’ AlphaView Dispergrader is a reflected light microscope designed to measure filler dispersion, including carbon black, and it explicitly states compliance with ISO 11345 and ASTM D7723 requirements for illumination angle. MonTech USA’s DisperTester 3000 Plus is positioned as an advanced automated optical dispersion tester for cured or uncured rubber, using telecentric optics, motorized panning, and digital image processing, with ISO 11345:2006 listed under standards.

Key Features of Carbon Black Dispersion Test Apparatus

A strong carbon black dispersion test apparatus typically includes:

- Reflected-light optics designed for dispersion analysis in rubber compounds, which aligns with ISO 11345 style assessment.

- Resolution and particle sizing capability, since both Alpha and MonTech highlight detection down to very small agglomerates, depending on the model and setup.

- Automated focus and repeatable scanning so results are less dependent on operator’s “feel.”

- Reporting outputs that labs can save and share, such as PDF or image files, which MonTech lists as available formats.

How Carbon Black Dispersion Tester Machines Operate

Microscope-based dispersion checking is straightforward in principle. A sample is prepared, placed under the microscope, illuminated, and then the operator or the software evaluates the size and distribution of carbon black clusters. Sipcon describes microscopy as giving a direct and visual observation of carbon black particles in the polymer matrix, which helps evaluate the dispersion pattern clearly. Automated systems add controlled lighting, image capture, and software thresholds so two operators can reach the same conclusion more often.

Step-by-Step Carbon Black Dispersion Test Method

A practical carbon black dispersion test method (rubber-focused, aligned with ISO 11345 intent) usually follows these steps:

- Cut a fresh, clean surface on the rubber specimen so the internal structure is exposed for viewing.

- Place the specimen under a reflected-light microscope and set magnification and lighting conditions appropriate for dispersion grading.

- Capture the image and rate dispersion against standard reference images, which ISO 11345 describes as the basis for a 1 to 10 scale rating.

- Record results and keep images with the batch record for traceability and troubleshooting.

For cable and polymer compounds, Sipcon also describes a microscopy workflow where a cable cross-section is exposed and examined, then dispersion is judged by particle distribution and cluster size.

Types and Variants

Dispersion systems are not all the same, and the best choice depends on whether the job is quick production screening or detailed lab investigation. Some factories prefer automation because it speeds up decisions and reduces arguments between shifts. Others still use manual microscopes for lower sample volumes or budget constraints, especially when a trained operator is available.

Manual vs Automatic Carbon Black Dispersion Tester Machines

| Point | Manual microscope setup | Automated system |

| Speed | Slower for many samples. | Faster for routine QC lots. |

| Consistency | More operator-dependent because grading is visual. | More repeatable due to controlled optics, scanning, and software processing. |

| Typical output | Visual rating vs references. | Rating plus saved images and digital reports (often PDF, JPEG). |

Industrial Applications of Carbon Black Dispersion Tester Machines

Common USA applications include:

- Rubber mixing and processing, where ISO 11345 notes the methods are intended as rapid factory controls during mixing and subsequent processing stages.

- Tire and technical rubber goods, where carbon black dispersion affects consistency and durability expectations tied to the compound.

- Cable insulation and sheathing compounds, where Sipcon highlights that dispersion affects mechanical and electrical properties and microscopy can reveal clustering.

Why Choose a Reliable Manufacturer

A reliable manufacturer matters because dispersion results guide real production decisions, like whether to rework a batch or release it. Alpha Technologies emphasizes that its instrument is designed around reflected-light methodology and states its illumination angle meets ISO 11345 and ASTM D7723 requirements, which helps labs defend the method during audits. MonTech emphasizes compliance, reproducibility, and repeatability for its series and lists ISO 11345 alignment and controlled optical and scanning features that support consistent readings.

How to Buy a Carbon Black Dispersion Tester Machine in the USA

Buying smart is less about the brochure and more about fit. Start with your material type and your required standard, then confirm service and spare parts access in the USA. A short checklist:

- Confirm whether your customers require ISO 11345 style dispersion grading (rubber) and whether your system is specified to meet it.

- Ask for a demo on your real compound and compare results to the ISO reference rating logic.

- If you work with cable compounds, make sure the supplier supports microscopy-based evaluation of cross-sections and can guide sample preparation.

- If you are also evaluating suppliers and content resources, SipconInstrument.com provides microscopy-based dispersion guidance for cables, and presents itself as a measurement-solutions-focused platform connected via shared author and contact information.

Final Thought

If the goal is dependable QC decisions, choose a system that matches your standard, your material, and your plant pace, then verify the vendor can support you locally. For many USA buyers, automated optical systems from established suppliers such as Alpha Technologies (AlphaView Dispergrader) and MonTech USA (Disper Tester 3000 Plus) are common shortlists because they clearly state ISO 11345 alignment and include features designed to improve repeatability. To get a precise recommendation, list your material (rubber or cable polymer), whether samples are cured or uncured, and your daily sample count.

FAQs

Q1: What is a Carbon Black Dispersion Tester and how does it work?

A Carbon black dispersion tester uses microscope imaging to visually assess how evenly carbon black particles are distributed, where good dispersion shows fine, even distribution and poor dispersion shows larger clusters.

Q2: Which industries in the USA use Carbon Black Dispersion Tester Machines?

Rubber manufacturers use ISO 11345 style rapid comparative dispersion assessment during mixing and processing, and cable compound producers use microscopy checks because dispersion impacts cable properties.

Q3: What is the standard method for performing a Carbon Black Dispersion Test?

ISO 11345:2006 describes qualitative visual methods that rate macro-dispersion relative to standard reference photographs on a 1 to 10 numerical scale.