Flash Measurement Systems & Image Dimension Machines in the USA | Precision Inspection

Flash measurement machines in the USA deliver ultra-fast, high precision inspection, helping manufacturers across automotive, aerospace, electronics, and medical industries improve quality, reduce errors, and boost production efficiency.

Flash testers ensure high speed precision

Manufacturing in the United States is changing faster since World War II. Industries ranging from automotive and aerospace to medical equipment and electronics are calling for more exacting, more efficient, and perfect quality. To face difficulties U.S organizations take the primary call; they are using new inspection tools which include flash measurement system, flash measurement machines. These are solutions that continue to redefine how manufacturers go about for validation combining high-precision, hard gauging with speed and adaptability.

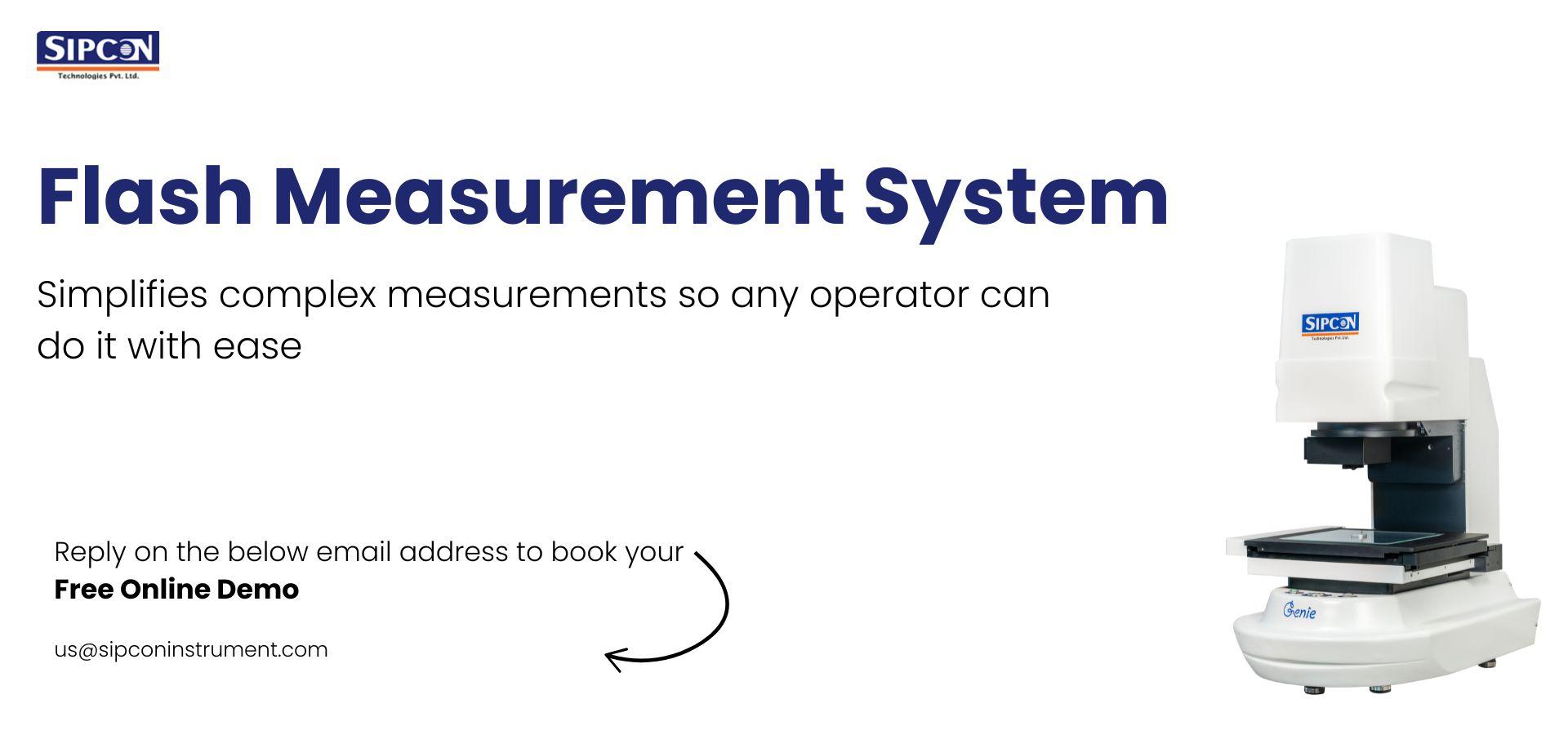

1. What is a Flash Measurement System?

A flash measurement system is a modern inspection technology that acquires dimensional characteristics in a second. Instead of employing manual tools like callipers or micrometres, it uses high-resolution optics and smart software.

For industries in the United States, the allure is clear: flash systems eliminate human error, expedite production, and deliver consistent results. Flash technology operates without physical contact and is very fast and scalable for high-volume fabrication facilities compared with other methods.

2. Flash Measurement Systems Advantages for U.S. Manufacturing

The benefits of implementing flash measurement are much more than just saving time:

- Non-contact ultrafast measurements – Users can inspect parts without touching them, eliminating the risk of damage to intricate products.

- Greater productivity and less time inspecting – What used to take minutes now takes seconds, allowing manufacturers to inspect more parts in less time.

- High Dependability for mass production – In applications where hundreds if not thousands of parts of the same design are made each day, part quality does not have to be checked after a certain time.

- The key benefits include why an increasing number of American manufacturers view flash measurement systems as necessary for remaining competitive.

- Flash measurement machines for features & applications

- The flash-assist measurement machine expands on the core technology of the flash measurement system, with functional elements tailored for industrial applications.

3. How does it Operates?

The machine captures an image of the part, processes that with some very powerful software and immediately creates dimensional data. No set-up, no Modifications and Practically an infinite number of readings for quick, accurate results.

Key Features U.S. Companies Value

- Fast – Measure hundreds of locations in seconds.

- Precision: Sub-Micron Level Accuracy for precision-critical applications.

- Automation – Simple integration in production lines also guarantees quality control on all manufactured products.

4. Applications in U.S. Manufacturing

Flash test equipment is common in those applications used in automotive testing, medical device manufacturing, electronics process control. Either way, the goal remains the same: ensure that parts are to exacting specifications, without slowing down production.

5. Image Dimension Measure Scope in the U.S.

Whilst other flash systems are there for speed and repeat ability, the system has a unique role in industries where very detailed viewing is necessary.

6. What It Is?

An image sizing system employs cameras of high definition and sophisticated software is used to quantify the part geometry using images. It is particularly sensitive., especially useful, and conveniently fragile, and small parts that could be marred by touching (or dropped). (The material is used in vacuum chambers).

7. Why Does It Matters in the U.S. Industries?

- Electronics – Check miniature parts and connectors.

- Plastics –Dimensional tolerances oversee moulded components

- Aerospace – Verifying intricate geometries and precision is a must

8. Flash vs. Image Dimension Systems

Both methods are non-contact and flash systems tend to prioritize speed over accuracy while systems use to focus on detailed image analysis. Most American companies rely on them both for complete inspection.

9. How to Select the most effective answer for your U.S. Business

It depends on what is important to you: flash system or Image dimensions.

- Accuracy requirements – Flash speeds today; image size for detail.

- Software features – Enhanced analytics and reporting can help you make better decisions.

- Scale-up systems – As your business blossoms and flourishes, it becomes crucial to have the ability to adapt and grow easily in response to the escalating demands of production. As your business flourishes and develops it is crucial to have the adaptability to adapt and grow easily in response to rising production needs.

- Local support – For U.S. companies, local suppliers and after-sales service mean less downtime and faster solutions.

10. Future of Metrology in the USA

The decade ahead will bring even more profound change:

- AI inspection – Inspect defects automatically and quality assured prediction.

- Integration into Industry 4.0 – Direct connection of measurement systems to smart factory networks.

- Further proliferation – As U.S. manufacturers increasingly understand the benefits, these systems will evolve from optional extras to become crucial aspects of industry norms, valued by businesses of all sizes. As American manufacturers increasingly understand the benefits, these systems will evolve from being seen as optional to becoming a crucial element of industry norms, embraced by businesses of all sizes.

The Making of Flash and Image Dimension Systems

For American manufacturers, implementing a flash measurement system or purchasing a flash measurement machine or an Optical measurement system has more than to do with replacing equipment: It is about remaining competitive in the world. These are speed, consistency and reliability that with the help of these technologies’ businesses fulfil their high requirements to quality and increase labour.

These systems are not optional in a world where reliability matters derived from precision, they are the future of American manufacturing.

Discover the Flash Measurement System Price that brings high accuracy without compromising your budget.

Contact us now: us@sipconinstrument.com

Visit: https://www.sipconinstrument.com/us/

Get Your Flash Measurement System Price Today and Upgrade Your Manufacturing Precision!

FAQs – Flash Measurement System & Flash Measurement Machine

1. What is a flash measurement system?

A flash measurement system is a non-contact inspection tool that captures dimensional data instantly. It helps manufacturers measure parts quickly, reduce human error, and maintain consistent quality.

2. How does a flash measurement machine work?

A flash measurement machine uses high-resolution optics and smart software to capture an image of a part, process it, and provide accurate dimensional readings within seconds, eliminating manual measurements.

3. Why are flash measurement systems important in U.S. manufacturing?

They enable ultra-fast, precise inspections for high-volume production. By using flash measurement systems, U.S. manufacturers in automotive, aerospace, electronics, and medical sectors improve efficiency and reduce defective parts.

4. What industries benefit most from flash measurement machines?

Industries like automotive, aerospace, electronics, medical devices, and precision engineering rely on flash measurement machines for quick and accurate dimensional checks, ensuring quality without slowing production.

5. How do I choose between a flash measurement system and an image dimension machine?

If speed and high-volume inspection are priorities, a flash measurement system is ideal. For detailed inspection of small or intricate parts, an image dimension machine is more suitable. Many manufacturers use both for complete quality control.