Vertical & Optical Profile Projectors in Australia or Cable Measurement – What, How & Why?

What is a profile projector?

A Profile Projector is an optical system designed to assess the specifications of small workpieces or tools and can project the shape, contributing to shorter part completion time’s overall part processing time. It does not encounter the part the way that traditional measurement systems do, which means there is no risk of damage and accuracy is high.

Profile projectors play a crucial role for industries in Australia for example cable manufacture, automotive, aerospace, electronics where they must to meet the most stringent of specifications. They are essential for:

- Geometry measurement: Size, diameter, angle, and profile of product.

- Ensuring the quality of goods: identifying issues before parts are dispatched if they are deviating from specification.

- Efficiency: Less time spent compared to manual analysis.

- Using a profile projector, Australian manufacturers can deliver all equipment up to international and local standards while following efficient processes

Understanding Vertical Profile Projectors

A vertical profile projector has a vertical stage, so it is suitable for measuring larger or heavier pieces. And here is why they come in so handy:

- Ergonomic: They can look at the projection image at eye level, without lowering head or raising chin.

- Footprint: Vertical construction minimizes factory floor space.

- Build your financial portfolio sharper vision: Great for cable inspection, accurate wire or measuring depth and coating inspections.

Applications in Australia:

- Check the cross sections of cables for consistency.

- Measurement includes automotive & electrical parts.

- Quality control for aircraft and aerospace parts.

- Vertical profile projectors allow the user to calculate with precision that can be reproducible and necessary for production environments where consistency is key.

- High Precision Optical Profile Projectors

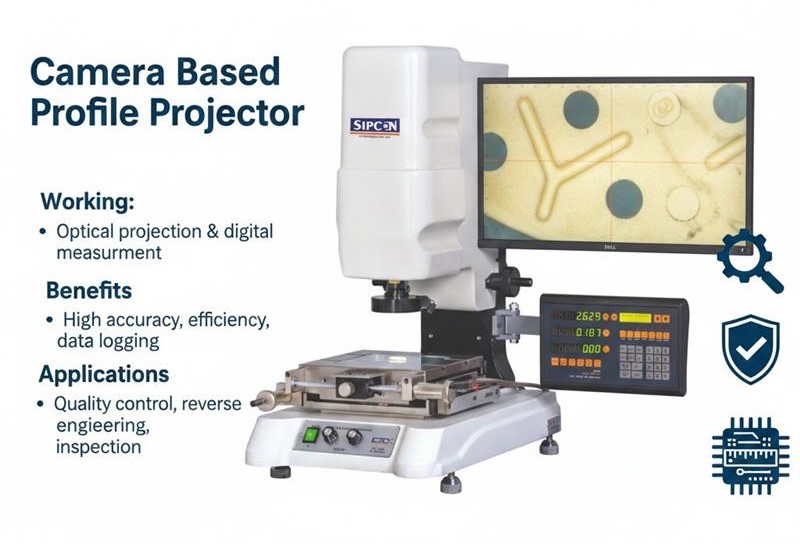

Where precision is a paramount, optical projectors can be the perfect option for many sectors. Advanced lensing and optical projection are employed to generate a clear, magnified image of the part which can then be measured on a screen.

Advantages of optical projection relative to manual check:

- High precision: detects the smallest differences in cable length, insulation depth, and surface quality.

- Swiftness: Instant results are eliminating the time wasted on manual measurement

- Conformance: Products are tested in line with Australian Standard (AS/NZS) and ISO.

Optical projectors help in generating QR codes, giving Australian manufacturers especially in cable production an advantage by detecting defects early while maintaining strict quality control.

Profile Projectors for Cable Manufacturing

Cables may seem simple, but precision is important. Differences in insulation, coating, and conductor alignment may lead to performance differences. A Profile Projector for Cable & Profile Measurement helps to:

- Detect flaws in Size of the cable, Thickness of insulation, Quality of coat.

- Make the two sides of the cable even all the way down.

- Comply with Australian and International Standards.

Production Profile projectors can be integrated into Australian cable manufacturers which is using production line to saving waste, rework costs and increase product reliability.

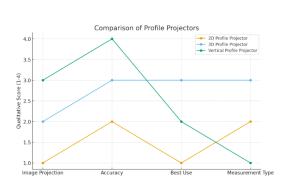

Comparison of 2D, 3D and Vertical Profile Projectors

| Feature | 2D Profile Projector | 3D Profile Projector | Vertical Profile Projector |

| Image Projection | Flat profile | Adds depth measurement | Vertical stage for large/heavy parts |

| Accuracy | High for flat components | High for complex surfaces | Excellent for wires, cables, and large components |

| Best Use | Simple components, wires | Complex geometries, multi-layered parts | Cables, wires, automotive parts |

| Measurement Type | Length, angle, width | Length, depth, contour | Diameter, profile, cross-sections |

- X-axis: Features (Image Projection, Accuracy, Best Use, Measurement Type)

- Y-axis: Qualitative Score (1–4)

- Lines: Each projector type (2D, 3D, Vertical)

How to Find the Right Profile Projector Supplier in Australia?

Choosing the best provider is a prerequisite for durable reliability. Key factors to consider:

- Lighting & software integration: These days you should expect Provides digital measurement and analysis features

- Service & calibration: Local service minimizes downtime and maximizes performance.

- Australian suppliers: good quality service and quick after-sales support, training, and calibration for a start.

The evolution of profile projectors in Australia

The Australian manufacturing industry is undergoing a transformation to a digitally-enabled and Industry 4.0 environment. The future of profile projectors are:

- Software linkage: 2D, 3D and vertical profile projectors linked to software for automated analysing and reporting.

- Increased automation: Reduced opportunity for human error, along with a more efficient production line.

- Applications beyond the industry: In addition to cables and wires, the automotive, aerospace, electronics, and medical sectors.

Start Your Quality Journey with SIPCON Instruments

To create and maintain good quality standards locally and abroad for Australian manufacturers, investing in vertical profile projectors, 2D profile projectors or 3D profile projectors is mandatory to stay competitive on a global scale

Profile projectors vertical, 2D, or high-precision optical systems are important tools for Australian manufacturers seeking accuracy, efficiency, and quality control. From cable production to aerospace, automotive, and electronics, these instruments help detect defects early, ensure compliance with local and international standards, and streamline production processes.

As the Australian manufacturing industry embraces digitalization and Industry 4.0, profile projectors continue to evolve & offering software integration, automation with enhanced measurement capabilities When a manufacturer invests in the appropriate projector and supplier, they know they can be precise, use less waste, and improve reliability – all of which makes profile projectors a staple of high-quality modern production. Write to us at export@sipconinstrument.com or visit www.sipconinstrument.com/au to start the conversation Contact Number: +61 426 368 868.