Profile Projectors in the USA | Optical & Digital Profile Projector Machines

In the American fast-paced world of manufacturing, precision isn’t just ensuring precision is an important aspect. From aerospace and automotive parts to rubber seals and electronic products, even the smallest deviation at this stage can lead to high errors. This is where profile projectors play a very important role and provide an effective, accurate & reliable way of inspection of parts & upholding high quality standards.

Digital profile projectors, in addition to regular optical profile projectors, are quickly becoming a part of modern U.S.-based factories that combine traditional methods with smart, automated measurement systems.

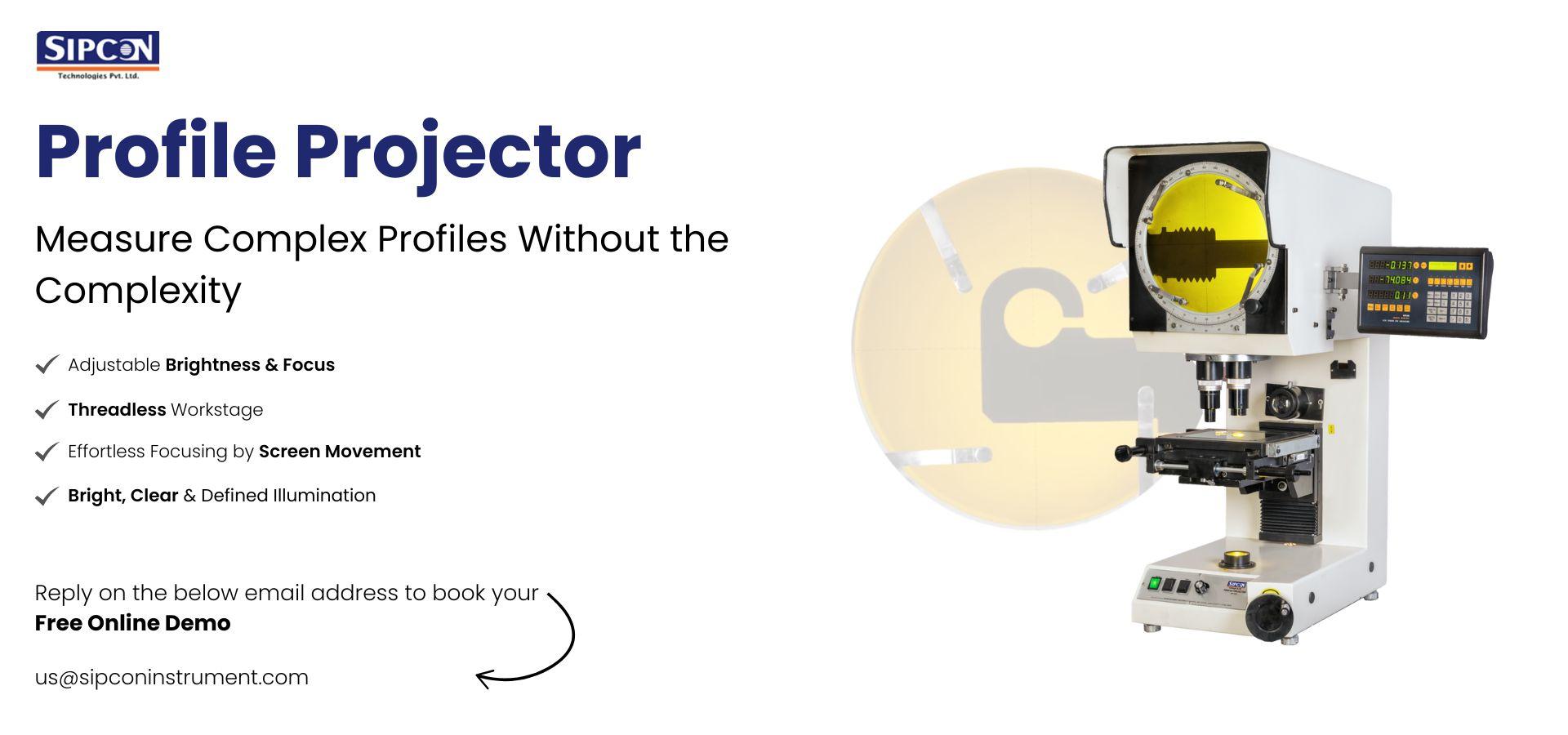

What is a Profile Projector?

A profile projector optical comparator or even shadowgraph, is a device that applies the principles of optics to the inspection of manufactured parts. It provides quality control technicians to evaluate the shape and size of the part – accurately.

3D scanning and CMMs have taken hold, profile projectors are still popular for several reasons:

- Require minimal assembly and maintenance

- Good value for small to moderate-volume production volumes

- Provide consistent performance for recurring inspections

And for industries that make small parts, including gears, rubber seals, cables or electronics, the machines are still the backbone of quality control.

Types of Profile Projectors Made in the USA

Optical Profile Projector

The traditional choice, often called the optical profile projector, projects a magnified image of a part onto a screen using lenses, mirrors, and controlled lighting. This setup will enable operators to exactly measure angles, dimensions, and contours accurately using simple tools like overlay grids.

Benefits of optical profile projectors:

- Simple to use and maintain

- Highly reliable for accurate measurements

- Cost-effective, especially for small-scale workshops

For these reasons, great numbers of American manufacturers still use optical systems because they provide a hands-on way to inspect parts with precision and without large digital overhead.

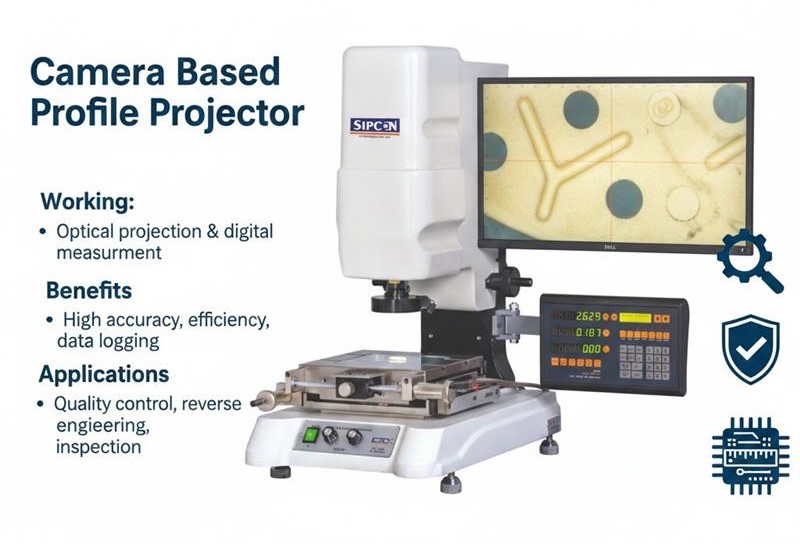

Digital Profile Projector

That is the digital profile projector, which is a combination of classical optics and modern technology. Using high-resolution digital displays and software, these systems allow an operator for automated measurements with electronic storage of results.

Advantages of digital profile projectors:

- Enhanced accuracy and precision

- Automated measurement and reporting

- All factory systems information at your fingertips – Integrate with Cedar, DMM and Jato

- Simple recording and reading of measurement results

- In many U.S. factories that emphasize automation, efficiency, and data-driven quality control, digital projectors are becoming a vital instrument.

- Profile Projector Machines- Use and Application Profile projecting machines is an optical device used to inspect the shape of an object.

- Profile projector machines today are built on the basis of different industrial requirements. Key features include:

- Variable 10x to 30x magnification for inspecting small parts

- Its adjustable lighting technology minimizes glare and enhances lamp performance.

- Big projection screens for better seeing and communicating with each other

Applications in U.S. industries:

- Cables & wares parts: Maintain thickness and cutting quality.

- Gearing & mechanical components: Checking the profile of teeth, angles and diameters

- Seal: Compare first with OEM seal up to Max, and second with the commonly available x2 types-find in description applicable; If not compatible, me-not fits!

- Electronics & PCBs – Checking small capabilities, including exact placement of components.

- American Moulding Technologies tells how profile projectors save manufacturers time and errors while assuring parts meet regulations and industry.

- Selecting the best profile projector manufacturer in USA

- Choosing a good profile projector manufacturer is important as the selection of the machine. Key considerations include:

- Accuracy and calibration: Guarantees you a reliable measurement

- After-sales support: Less downtime and learning curve

- LOCAL V.S GLOBAL Manufacturers – Local Manufacturers can respond quickly but global manufacturers may have advanced features.

For American companies, working with a reliable manufacturer results in access to premium machines and responsive support—key for keeping up with manufacturing processes and maintaining high quality.

Why American Industries Depend on Profile Projectors

Even after the emergence of high-tech tools 3D scanners or CMMs, profile projectors have not lost their necessity because:

- Flexible: Capable of inspecting multiple materials and types of parts

- Affordable: High-accuracy alternative to complicated machine tools at a fraction of the price

- Durable: Inspectors have used these for quality lasting decades

Today, they still provide fast and exact results that are found in manufacturing plants in the United States

The Future of Profile Projectors in the United States

The transformation of digital profile projectors in quality control is changing the status quo. Today with smart manufacturing and Industry 4.0, these machines will instead provide you:

- Integration with factory data systems

- Automated reporting and measurement documentation

- Improved accuracy, even on the most complicated parts

While the United States embarks on adopting smart factories and digital QMS systems, profile projectors, in both optical and digital options, will still be important instruments for measuring precision.

Conclusion

Profile Projectors/T2 Demonstrating the way we do It in American Manufacturing

Whether you are going old-school with an optical profile projector or high-tech with a digital profile projector, these machines help American workers keep precision standards and efficiencies at their highest levels in just about every sector that matters. Investing in the right profile projector machine from a top profile projector manufacturer can revolutionize your quality control processes, eliminating errors and keep you competitive in today’s world.

Looking for the Best Profile Projector Price?

Whether you prefer an optical or digital profile projector, we have the right solution to boost your quality control, eliminate errors, and increase efficiency.

📧 Email: us@sipconinstrument.com

🌐 Website: www.sipconinstrument.com/us/

📞 Call Now: +1 (262) 391-4785

Get the latest Profile Projector price and choose the perfect machine for your needs today!