Digital vs Optical Profile Projectors: Which One Should You Choose?

Explore the key differences between digital and optical profile projectors in India. Find out which profile projector is perfect for your manufacturing needs for precision and efficiency.

Digital vs Optical Profile Projectors in India: A Complete Guide

Precision is not just an advantage, but a necessity in India’s fast developing manufacturing and engineering sectors. Be it automotive parts, electronics or in metal fabrication measurement slip-up, big or small, can throw off your whole process., can result in defects, costs involved or recalls. To mitigate this, manufacturers use profile projectors to gain a clear, magnified idea of specific measurement the profile of a part.

Nonetheless, thanks to advances in technology, manufacturers must now ask the significant question: Do you buy a digital profile projector instead of an optical profile projector? This article explores the intended uses and advantages of each option and will help Indian engineers and shop owners deliberate on which projector to buy.

Understanding Profile Projectors

A profile projector is a shadowgraph; a profile projector is an accurate measurement tool assessing dimensional and geometric assessment of small parts. Operators can inspect the profiles, evaluate tolerances, and confirm parts meet specs by magnifying and projecting the object onto a glass screen.

Profile projectors can be widely found in:

- Automotive parts quality check

- Manufacturing of electronics

- Manufacturing of tools and dies

- Aerospace parts quality control

In India, where precision manufacturing is using the latest manufacturing technologies and quickly evolving profile projectors play a crucial role in maintaining global standards and reducing material waste.

Optical Profile Projector: The Traditional Solution

The optical profile projector is the traditional version that has served manufacturing and other industries for many decades. The system relies on controlled lighting and lenses to project an image of the parts onto a screen.

Benefits of optical profile projectors:

- Accuracy with reliability: Advantageous for each measurement and regular inspections

- Low maintenance: Fewer electronic parts reduce the likelihood of breakage

- Ease of operation: Requires minimal training, upgrading the capability of a workshop

- Sturdy: Fit for factory floor environments

Drawbacks:

- Manual calculations slow the production/blurring time

- Next-generation digital analysis and data storage are not available

Best For:

- Budget conscious workshops

- Routine inspections where high-speed digital analysis is unnecessary

Digital Profile Projector: The Modern Approach

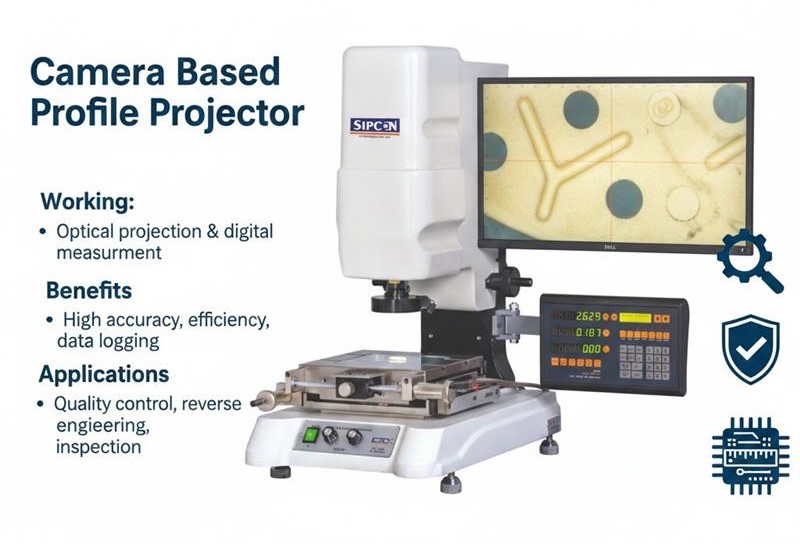

Digital profile projectors use cameras, sensors, and software to capture, display, and analyse parts digitally.

Advantages of Digital Profile Projectors:

- Improved Accuracy: Enables the identification of very minor changes.

- Record and Analyse Information: Measurement records can be monitored and analyzed over time.

- Quicker Inspections: Increased throughput through fewer manual measurements.

- Software Integration: Can be integrated with programs or précised quality management, reporting, and statistical analysis.

Disadvantages:

- Greater upfront cost compared with optical systems.

- Needs trained operators and regular software updates.

Best For:

- High-tech manufacturing environments

- More detailed parts that needs more detailed analysis

- Factories looking to digitize their process for quality control

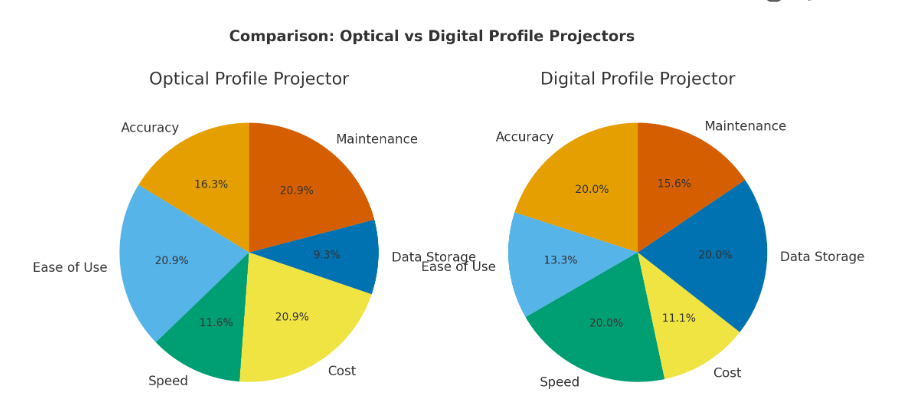

Digital vs Optical: Side-by-Side Comparison

| Feature | Optical Profile Projector | Digital Profile Projector |

|---|---|---|

| Accuracy | High, reliable for common parts | Very high, perfect for micro-tolerances |

| Ease of Use | Simple, minimal training | Requires training, software familiarity |

| Speed | Manual measurement | Faster, automated measurement |

| Cost | Reduced upfront cost | Greater upfront cost |

| Data Storage | Manual, visual documentation | Digital storage, analysis, reporting |

| Maintenance | Low | Moderate, software updates need |

Choosing the Right Profile Projector for India

While deciding on which system to invest in keep in mind:

- Cost: Generally, optical systems will have a lower upfront cost and are therefore more attractive to a small-medium sized workshop-type company.

- Complexity of components: If your parts are complex geometries, or require micro-measurements, a digital system is a better choice.

- Production Volume: High-volume operations benefit from digital systems due to speed and data tracking.

- Future Growth: Digital projectors allow factories to adopt Industry 4.0 practices and automation.

Many Indian manufacturers are now adopting a hybrid approach—using optical projectors for regular test and digital projectors for detection or quality inspections.

Final Considerations

Both digital and optical profile projectors are important instruments for precision manufacturing in India. The choice depends on your factory’s budget, structural complexity, and production goals.

- For traditional workshops an optical profile projector continues to be the solution if choice

- For high-tech, high-precision manufacturing environments, a digital profile projector provides speed, accuracy, and improved data capabilities.

- Investing in the right projector provide measurements, minimizes material waste, maintains quality standards, and positions your business to compete in global markets.

Conclusion and CTA

Choosing the right profile projector helps your factory keep precision and quality maintain high standards. Conventional optical profile projectors are dependable, durable, and cost-effective for daily inspection requirements. Digital profile projectors provide better accuracy and efficiency by offering advanced measurement methods and data processing capabilities. Selecting one of these systems depends on your production demands, the level of complexity of your parts, and your anticipation of future advancements. Do not risk precision optimize your measurement processes to ensure that every part meets both your internal and international standards.

Contact our team at info@sipconinstrument.com or reach us at +91 82229 29966 to find your profile projector digital or perfect for visual measurement tasks for the Indian manufacturing industry. Let us take the first step towards smarter, faster, and more précised inspections. Visit us at: https://www.sipconinstrument.com