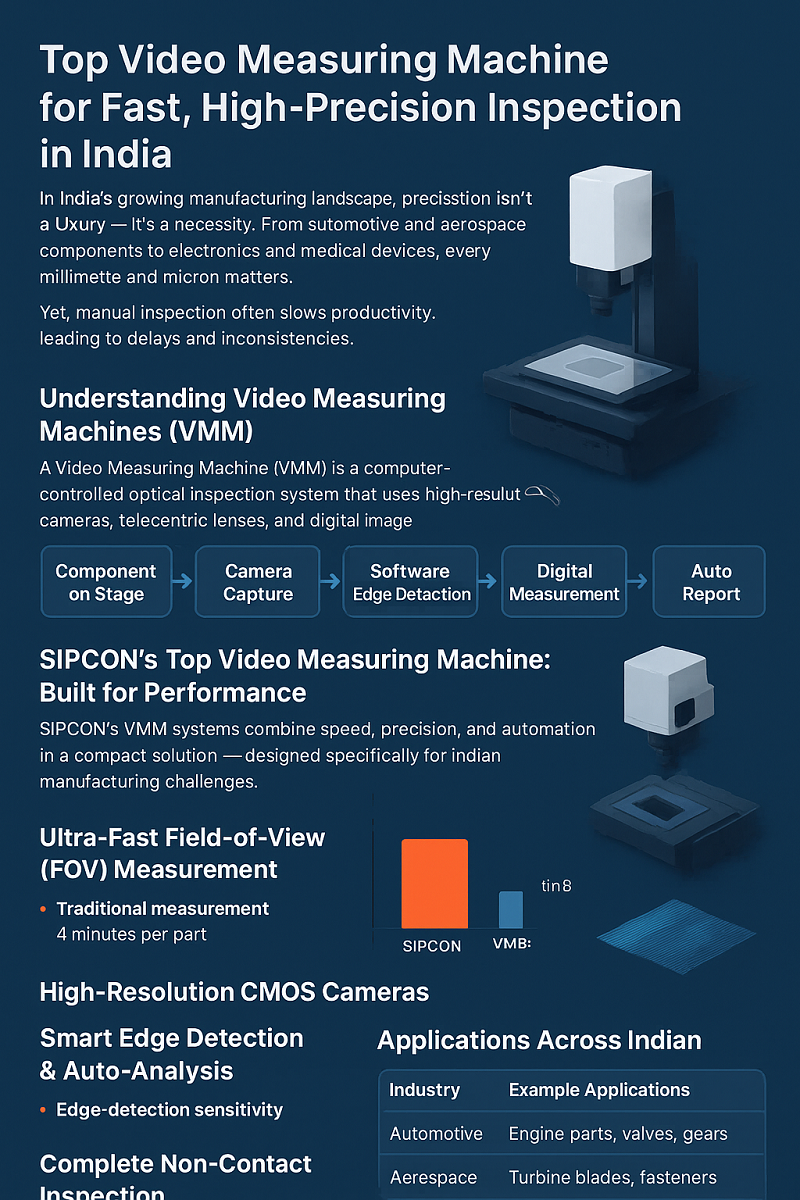

Top Video Measuring Machine for Fast, High-Precision Inspection in India

In the manufacturing ecosystem that is evolving at high speed before, precision is the defining value of performance. All industries like automotive, aerospace, electronics, medical devices, or others needs parts to be manufactured with the tightest tolerances. If the tolerances are off by even a micron, the products produced may malfunction, be dangerous, or that the efficiency is compromised. Traditional measurement methods often fall short devices/tutorials do not meet the requirements of today’s Production facilities. Manual inspections are slow, unreliable, and impossible to not be influenced by humans. Industries need inspection systems that can detect faster and gives better precisions, and be integrated into automated production environments. This is where SIPCON Technologies positions its Top Video Measuring Machine to combine high speed, precision accuracy, and high level of intelligence to change the quality control section for Indian manufacturers.

Understanding Video Measuring Machines (VMM)

A Video Measuring Machine (VMM) is an optical inspection measurement system that is non-contact and uses cameras, high-precision lenses, and powerful software to check and measure the size of a part. A VMM will never make contact with the part, unlike a contact measuring device (like CMM or micrometre), to ensure zero deformation, zero friction, and zero impact on the measurement. The machine employs an optical source for illumination, to produce high-resolution images of the part. In the inspection process, the VMM detects the edge of the object and calculates the accurate measurements the user requires in real time.

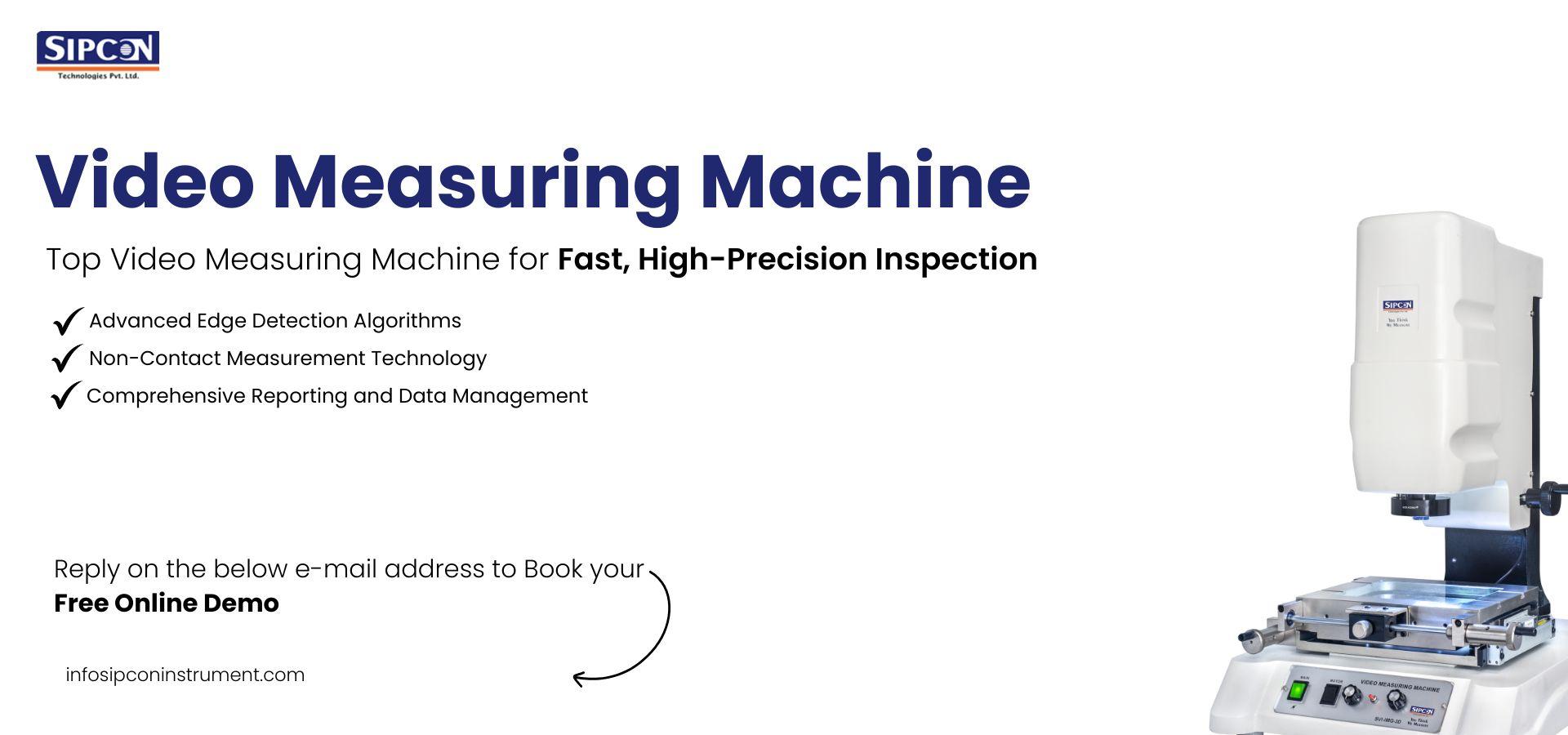

SIPCON’s Top Video Measuring Machine: Built for Performance

SIPCON’s Leading Video Measuring Machine: Engineered for Results SIPCON’s VMM systems combine speed, precision, and automation in one compact solution, engineered specifically for manufacturing challenges facing India.

Highlights and Benefits –

- Ultra-Fast Field of View (FOV) Measurement

SIPCON’s Field of View (FOV) system can take multiple measurements within a single camera shot, greatly minimizing inspection time. No more re-scanning or repositioning of the part Entire parts measured in a matter of seconds Up to 70% faster throughput than coordinate measuring systems

- High-Resolution CMOS Cameras

Each VMM uses a megapixel CMOS camera and telecentric lenses which provide distortion-free imagery with no distortion at the edges. Consistent precision regardless of surface reflectivity or illumination conditions Accuracy: ±1 µm Repeatability: ±0.5 µm Depth of Field: Optimized for large and small parts Smart Edge Detection & Auto Analysis The system’s intelligent software automatically detects part geometry circles, lines, curves, angles, calculates the results instantly.

- Complete Non-Contact Inspection

Because SIPCON system is purely optical it guarantees: No contact with the part No scratches or deformation on the part surface Ideal for delicate, micro, or soft components This is particularly important within electronics, plastic moulding, and medical device manufacturing, etc., where even the smallest component or scratch could result in rejection.

- Instant Reporting & Traceability

After inspection, SIPCON’s VMM automatically produces thorough digital reports that include all dimensional values, pass/fail analysis, and graphical data overlays. These reports can Be exported as PDF, Excel, or SPC Be integrated with ERP or MES systems Be stored for ISO or traceability audit purposes This assists compliance and strengthens process control. This is a fully automated cycle that enables accuracy and reliability without reliance on operator skill or manual judgment.

Applications Across Indian Industries

SIPCON’s Top Video Measuring Machine is widely used in:

| Industry | Example Applications | Benefits |

|---|---|---|

| Automotive | Engine parts, valves, gears | Fast dimensional checks, fewer rejects |

| Aerospace | Turbine blades, fasteners | Extreme precision under tight tolerances |

| Electronics | PCBs, connectors | Non-contact micro inspection |

| Medical Devices | Surgical tools, implants | Sterile, accurate measurement |

| Tooling & Dies | Mould inserts, punches | Better repeatability & alignment |

SIPCON Advantage: A Complete Ecosystem of Precision

SIPCON’s success relies on technology, trust, and localized expertise.

- Indian-engineered, globally fused designs

- AI-powered measurement algorithms

- User-friendly software interface for minimum training

- Pan-India support network for fast response

- Upgradable systems for automation and robot partnerships in the future

Customer-Centric Impact

Manufacturers in India are reporting improvements of:

- Inspection speed: improved 3X

- Manual errors: cut 40%

- First article inspection: improved turnaround time by over 50%

This experience reinforces SIPCON’s VMM as more than a machine, but instead a partner for quality improvements.

Three-dimensional Visual Concept: The Advantages of SIPCON

- Accuracy

- Reliability

- Automation

- Scalability

- Local Support

Conclusion and CTA

In a world that emphasizes precision and efficiency, SIPCON Technologies continues to lead the way in measuring innovation in India. The Top Video Measuring Machine provides fast and reliable inspection results with high accuracy, allowing manufacturers to not only meet global quality expectations, but also get a competitive edge in their local markets. Whether you are producing micro-parts or large assemblies, SIPCON’s vision systems provide you the ability to measure more, inspect faster, and ship more confidently. Are you ready to take advantage of India’s Top Video Measuring machine? Enhance your production experience with SIPCON’s next generation inspection systems. Please feel free to contact us at info@sipconinstrument.com or check out our website at https://www.sipconinstrument.com

📞 Phone: +91 82229 29966