Die Drawing Measurement Machines & Geometry Inspection Systems in Russia

In Russia’s booming wire, cable and metal processing industries, accuracy is not a hope: it is a necessity. Each wire that powers an industrial machine or connects electrical grid begins with one crucial part the drawing die. The measurement of these dies to the highest level of accuracy has a direct correlation to product quality, service life, and performance.

That is where drawing die measurement systems and geometry inspection machines come into play scientifically with specialized tools from IDC that marry science, technology, and precision to make manufacturing a continues process.

What is Drawing Die Measurement?

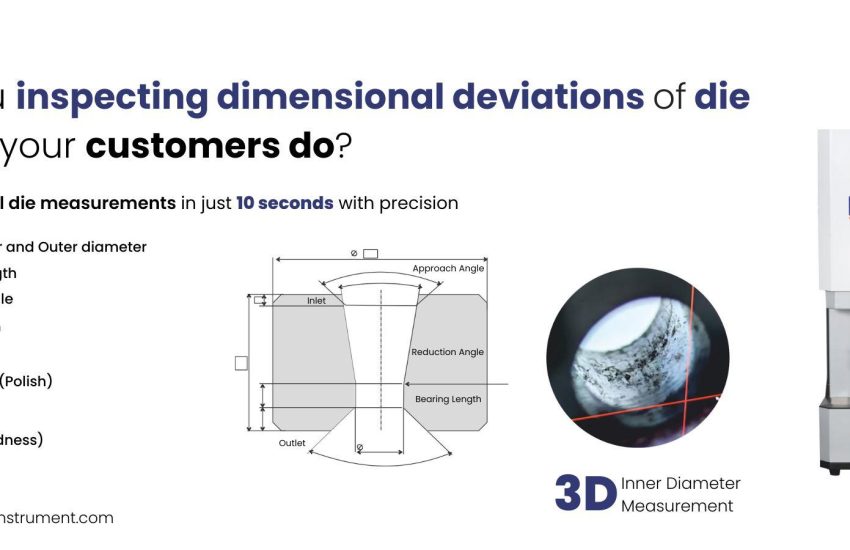

Wire Drawing Die Lights Instruments Industry Tools (0.751-2.600mm) Artists, Crafts Studio Artists. A drawing die is a precision tool that uses a small amount of working wear with wire or metal and to cut the desired shape, when smaller size is needed. This steel Mold reduces the diameter will be pulled out of copper wire. Use for Wire Drawing without case note: including 3 pieces on the Picture. Even minor wear and deviation in the die’s geometry could affect the wire measurements, its strength, and production efficiency over time.

Die measurement is inspection of the die’s internal geometry diameter, roundness, and angles to ensure they are exactly as specified. With Russia’s fast-growing industry of manufacturing and energy production, you can be sure that every wire is built for consistency, Its strength and reliability.

In industries like power transmission, automotive and telecommunications, maintaining that die geometry consistency is not only about accuracy however it is a matter of establishing confidence in every single meter produced.

Key Parameters in Drawing Die Geometry Measurement

Measurement of drawing die geometry Analysing the elements of the die and their nature that determine its effectiveness. This even goes for diameter, roundness, taper and angle meaning every die runs in exacting tolerances.

The demand for measurement of drawing die geometry in Russia is growing, in industrial clusters: Moscow, St. Petersburg, Yekaterinburg and other regions with large-scale production of wire and cable products. Precise geometric control allows Russian manufacturers to adhere to the rules of the rest of the world, so that all ready-produced products meet ISO / IEC standards.

Benefits include:

- High repeatability and measurement reliability

- Reduced scrap and rework costs

- More consistent control over surface quality and wire consistency

Drawing Die Measurement Machines accuracy in numbers

The production process of drawing die you would have seen that it is difficult if not impossible to use directly CNC measurement machines calibrated even twice or three times in just 30 days.

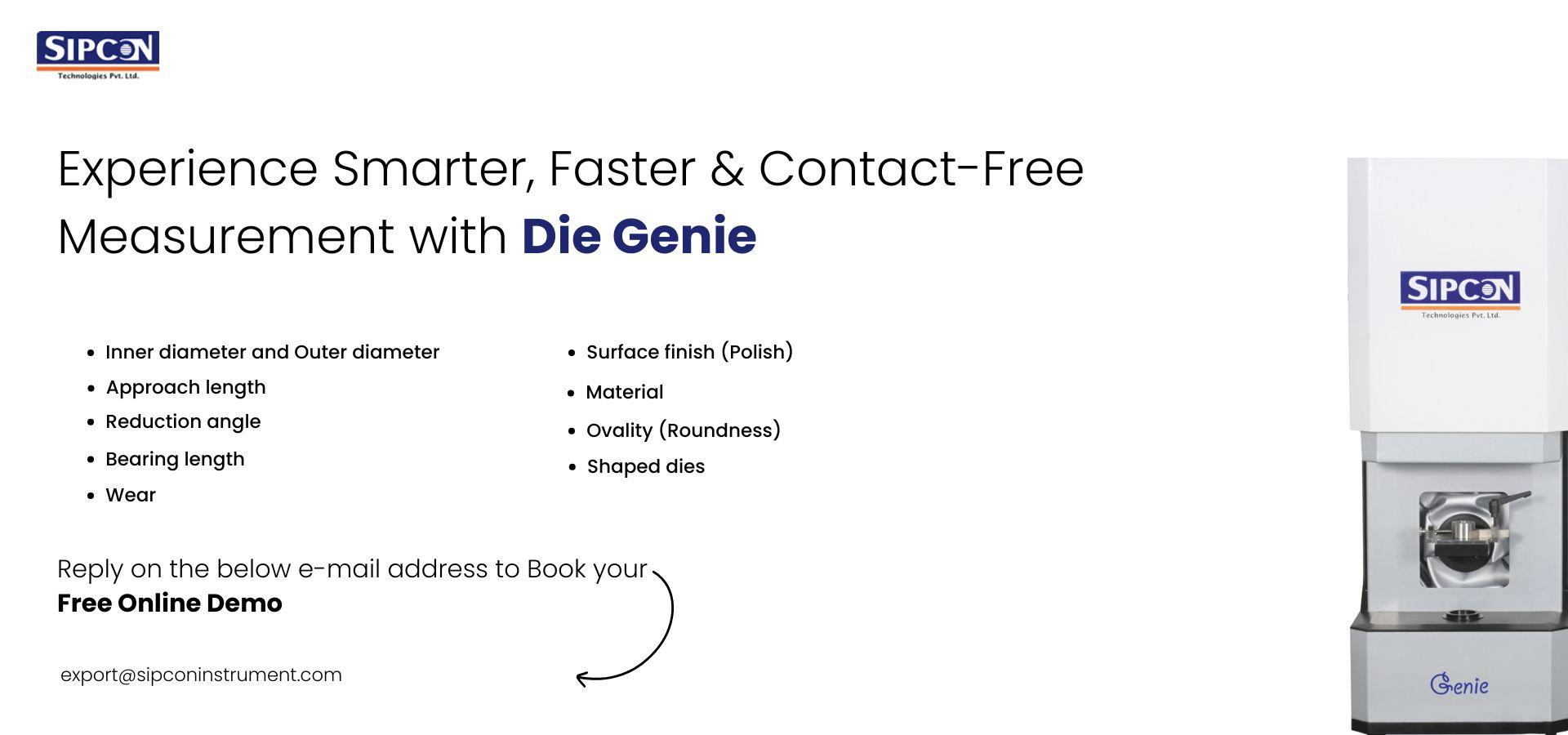

The current drawing die measurement machines are designed for high throughput, accuracy-oriented markets. They employ cutting-edge optics, non-contact sensors and automatic methods for collecting data to provide high-accuracy and repeatability tests measured in seconds.

These machines provide Russian production sites:

- Repeatability – Provides exact measurements every die, every time.

- Operability: Intuitive software for both operators and technical staff.

These machines are used in the factories of Russia’s industrial centres to inspect drawing dies during and after production thus helping minimize downtime and maintain a uniform rhythm of production.

Measurement Systems for Dies to Draw

The next step to precision is the draw die 3-D profiling system. In contrast to conventional 2D methods, these systems record a full 3-D map of the die geometry. This allows operators to inspect the complete structure of the die, including angles, radii and surface imperfections in live time.

Advantages of 3D profile measuring systems:

- Full geometric visualization

- Rapid assessment of wear and distortion

- Comprehensive assessment of surface quality of the dies

For these Russian companies that manufacture high-end cables, wires for aerospace or precision metal parts tooling features provided by the 3D systems can enable faster decisions, fewer rejections and Enhanced production levels control potentials.

Complete Drawing Die Measurement Systems

A Drawing Die Full Measuring System consists of a 2D and a 3D geometry inspection in the same integrated platform has been developed. It not only measures the internal shape of the die and simultaneously offers the data to a dedicated software package for more sophisticated analysis and reporting.

These systems provide pass/fail automated results, detailed geometry charts and historic measurement data to allow Russian manufacturers to monitor quality trends and make corrective actions in a timely fashion.

Connection to production software The interface options allow companies to link their measurement systems to Industry 4.0 platforms, creating more effective factory operations and improving traceability.

Drawing Die Inspectors in Russia

Now, the drawing die inspector is a key factor guaranteeing both the quality and lifetime of a die. They are anything but condition-insensitive testing systems, detecting in flex fatigue damages or surface cracks the smallest deviations such as wire damage coming through adjacent to a knot.For Russian enterprises, the die for the tensile inspector should:

- Detect early-stage die wear

- Prevent costly production halts

- Minimize die wear through regular maintenance

With drawing die measurement machines and drawing die inspectors, manufacturers can ensure consistently high-quality levels and reduce waste as well as related production costs.

Making the Right Measurement System Selections in Russia

Manufacturers have a few key considerations when choosing an optimal drawing die measurement system in Russia which are: Accuracy, speed of resolution, cost and level of automation.

Here is what to remain cognizant of:

- Precision – select systems that can operate at micron scale accuracy.

- Speed – choose automated systems that respond in a few seconds.

- Cost: Consider a balance between things that are technically advanced and return on investment in the long term.

- Back-up: Check who provides contact, support and back up calibration or service in Russia.

And with trusted partners such as SIPCON Technologies, Russian-based manufacturers can take advantage of dependable software support and configuration services from a technical expert all from the same people.

Do we Know the Prospects for Measuring Drawing Die Sin Russia Type publications are general contract?

Digital inspection and automation technologies are becoming increasingly popular in the Russian manufacturing. The future of geometry measuring systems for the drawing die is based in AI integrated machines as well as Industry 4.0 platforms that predict wear limits, optimize inspection timing and generate condition-based alerting to preserve gage life.

With the rise of smart factories, implementation of automated drawing die measurement systems will be central to maintaining Russian competitiveness in the era of Industry 4.0 facilitating innovation, quality and sustainability.

Stable and Accurate Measurement of Drawing Dies for Manufacturing

From 2D geometry checking to 3D profile measurement systems: Technology of wire drawing die measurements Revolution in the Russian cable and wire manufacture Not only that these systems ensure quality while providing both long-term savings and efficiency, but also customer confidence. For manufacturers in Russia who want to be ahead in precision and reliability, SIPCON Technologies provides global standardised drawing die measurement machines, drawing die geometry inspection tools as well as fully-equipped 3D profile measuring systems that help production lines to run without fail Introduce the advanced drawing die measurement systems in Russia where technology meets precision and each micron matters.

Check Drawing Die Measurement Systems Price Today!

Looking for precise Drawing Die Measurement Systems Price in Russia? SIPCON Instrument offers high-quality measurement systems with reliable performance. Visit us at 454080 Engelsa ultisa, 83b, office 1, Chelyabinsk, call +1800 412 2375, or email export@sipconinstrument.com to get a quote and know the Drawing Die Measurement Systems Price now!