Video Measuring Machines & Flash Measurement Systems in Russia Accuracy Re-imagine

The industrial environment in Russia is changing quickly with the aerospace, automotive, electronics, heavy industry industries looking more and more to high-precision measurement solutions. Old school inspection methods often cannot match the pace of moderns and refuse to compromise on quality. Introducing Video Measuring Machines and Flash Measurement System. A lot of new technology that is changing the landscape in which Russian industry measures accurately to ensure key parameters are maintained in product design and quality control. With these sophisticated tools, it is not just about measuring parts it is about increasing productivity, decreasing errors, and creating smarter manufacturing.

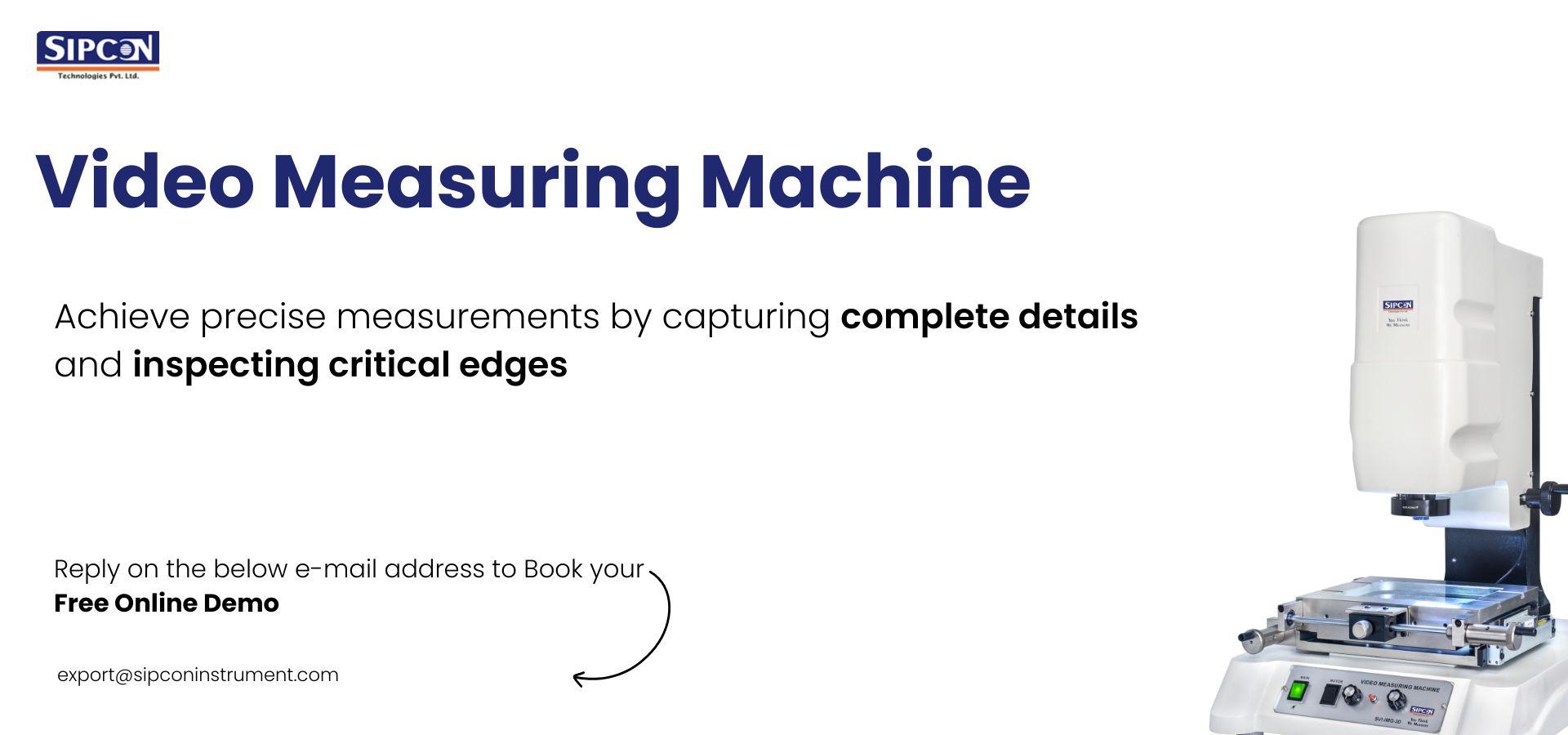

Video Measuring Machine Suppliers in Russia

Video measuring machine (VMM) is a contactless optical system that measures and analyses geometry of the part with high accuracy based on imaging technology. Unlike traditional micrometres or callipers, Vision Measuring Machines (VMMs) uses high-resolution cameras, precision optics, and intelligent software to makes them important in industries, where even the smallest deviation can lead with high precision loss.

There are benefits of using Video Measuring Machines. They provide accurate, non-contact measurement that protects fragile parts from damage. Most Systems can directly communicate with the plant automation system for data logging and trend analysis and quality reporting. This streamlines the process, minimizing human input and increasing overall productivity.

Russia prominent VMV companies have already penetrated the Russian local market provide industrial solutions. Such suppliers specialize in customization, or tailor -making the machine ng process to growing from small tool room all the way up to large aerospace facilities, that precision is t at every step of the manufacturing process.

Flash Measurement Systems – Speed and Beyond

Measurements of flashes is the next system frontier for industrial inspection. In comparison to traditional measuring machines, this metrology design system detects measurements in up to 3D with a fully automated high throughput. The operating principle is imaging in high speed a piece from different sides and a sophisticated algorithm computing object’s precise dimensions are captured quickly.

For Russian companies producing large amounts of products, the flash measuring devices are revolutionary. dimension lines can run non-stop because these inspectors are so quick.

Industry Flash Testing Machines

The flash measurement equipment is widely applicable and the interest of Russian producers in it has a likely to increase. Auto makers employ them for checking engine parts, gears, and chassis components with minimum downtime. Manufacturers of electronics use them to check online PCB dimensions and connector positions, and aerial vehicle manufacturers benefit from accurate examination of turbines and structures. Flash machines are also used by tooling industries to precision grind Molds and dies.

The benefits are obvious: increased speed [reduced throughput], decreased errors, and vastly reduced inspection time. By substituting slow manual measurements with flash measurement systems, Russian industries are still able to meet their aggressive production requirements all while verifying top-quality project results. That is why demand for that equipment has been growing in several industrial sectors of Russia.

Systems for Image Dimension Measurement in Russia

Inspection by imaging, image dimension measurement system Inspection has never been this visual, revolutionary inspection for cutting edge – “innovative new exposure”! These systems, which are equipped with high resolution cameras and proprietary software, are able to measure multiple characteristics on a single part at the same time enabling fast multi-part inspection combined with the preservation of high levels of repeatability.

In Russia, such systems are more and more used in the electronic industry, medical equipment production and metal items processing. – Manufacturers of fragile medical instruments can go even further by image-based inspection to guarantee that every part meets highest quality requirements. Equally, manufacturers of electronic components get quick and easy connectors, chis and assemblies’ inspection without the risk of producing defective items on the market. The high speed, precision, and flexibility of image-based dimension measurement systems have made them essential for the modern Russian industry.

Video vs. Flash Measurement Systems Compared

Although both VMMs and FMS meet the need for precision inspection, they do so in fundamentally different ways. We distinguish VMM from flash systems as we go; such measurements are capable of both high-precision measurement (in the case of parts that are individual or few in number and highly complex) and fast, real-time inspection (when dealing with a large population).

The choice of which to use is a matter of production preference. VMMs are what you need if your application is intended for close examination of detailed parts. On the other hand, for such industries where there is huge production in repetition flash measurement machines offer better application. Many Russian manufacturers now have merged these two technologies so you get the best of both worlds and compromise in either, a ‘hybrid’ printable and stitch solution, detailed precision with speed.

Selecting Measurement Tools in Russia

Choosing the right measuring technology is a key challenge as Russian industry strive to reach high levels. Considerations include accuracy, compatibility with software, scalability and how easily they can be integrated into your existing production lines. Apart from technical capabilities, post-sale service and operator training is also crucial in order to facilitate the uptake of technology and warrant its effective operation.

Collaborating with a reliable video measuring machine manufacturer or flash system provider is essential. Responsible manufacturers not just hardware, software support implementation services Upgrade, maintenance, and training courses, to ensure that Russian factories can maximize the use of precision inspection on investment.

Market Share by Industry Using Measurement Systems in Russia

• Automotive – 35%

• Electronics – 25%

• Aerospace – 20%

• Medical Devices – 10%

• Tool-making & Others – 10%

Adoption Rate of Measurement Technologies in Russian Manufacturing

• Video Measuring Machines – 40%

• Flash Measurement Systems – 35%

• Image Dimension Measurement Systems – 25%

The prospects of Russian metrology equipment industry

Automation and smart production technologies are the basis for the future of industrial measurement in Russia. Artificial Intelligence (AI) based inspection tools, integration with robots and adoption of Industry 4.0 is converting the conventional processes to automated and intelligent systems. Demand for quicker, smarter measurement systems will rise and with assets such as video measurement, flash measurement and image dimension measurements solutions installed in all key industries.

As Russian factories become modernized new requirements appear for manufacturers in terms of systems, which would measure, analyse, forecast, and report defects with regard to real time. This method not only prevents waste, but also helps make informed decisions about production planning and quality assurance.

Conclusion — Accurate Measuring Instruments for Russian Industry

In summary, video measuring machines, flash measurement systems and Video Measuring Machines are used in the factories of Russia for the requirements of manufacturing 。 These technologies are a perfect balance between accuracy, speed and versatility so parts can meet the tightest tolerances without holding up production.

Competing without the right technology is no longer an option–it is a strategic decision that protects quality, drives efficiencies. Russian companies that want to still be giving performance solutions like video or flash measuring systems, can learn equipment for production at industrial panorama. Achieve higher precision with our advanced Video Measuring Machines and Flash Measurement Systems in Russia. Visit us at 454080 Engelsa Ulitsa, 83b, Office 1, Chelyabinsk, Russia. Call +91-9215699661 or email export@sipconinstrument.com to get expert guidance and elevate your dimensional inspection accuracy.