How to Calculate CMM Least Count?

In today’s manufacturing being accurate today isn’t just a nice-to-have; it’s important. Whether you’re making precision machined parts, plastic moldings, parts used in automotive sectors and assemblies used in aerospace industries dies, tools, devices, and medical devices, measurement accuracy is at the core of delivering quality. And when it comes to this, the Coordinate Measuring Machine really stands out.

Now, there’s one term that tends to pop up a lot but often doesn’t get the attention it deserves: CMM least count.

For many engineers and operators, least count feels like one of those textbook phrases. They memorize it but may not fully understand how it affects actual measurement results, customer approvals, tolerances, and consistency in inspections.

In this blog, aimed specifically at an Indian manufacturing audience, we’re going to dive into what CMM least count actually means, how it’s calculated, and why it’s so important today. We’ll also touch on the contributions of SIPCON Technologies, a reliable name in metrology and inspection solutions across India.

What Exactly Is “Least Count”?

Before we dive into CMMs, let’s break down the term a bit: Least count refers to the smallest measurement an instrument can reliably detect and repeat. So, if you have a vernier caliper with a least count of 0.02 mm, that means it can pick up changes as tiny as 0.02 mm. Now, when it comes to CMMs, the same principle holds true, but there are more factors at play. You’ve got machine resolution, scale accuracy, mechanical stiffness, probing system performance, and how stable the environment is all influencing the calculations. So, when we mention CMM least count, we’re really talking about:

What is the smallest dimensional difference this CMM can reliably detect?

This has a direct impact on:

- Part approvals

- GD&T evaluations

- Customer audits

- Cpk/Ppk studies

- Inspection consistency

- Tool offsets

- Supplier credibility

In Indian industries, where competition is fierce, export demands are increasing, and the need for high precision is growing, grasping this small detail can truly make a difference.

Why CMM Least Count Matters in Real Manufacturing

You might be thinking, “Does it really matter if the CMM shows a difference of 1 micron or 2 microns?” Well, it definitely does. Here’s the scoop:

Customer Tolerances Are Getting Tighter

Industries like automotive, aerospace, die-making, and electronics are constantly pushing for tighter GD&T tolerances year after year. If your machine’s least count is too big, you could end up with false rejections or falsely accepting parts.

CMM Data Drives Production Decisions

The readings from a CMM are crucial for:

- Adjusting CNC offsets

- Validating mould and die performance

- Approving batches from suppliers

- Preparing PPAP documentation

If you get a measurement wrong, it can mess up everything that follows.

Field Competition in India Has Intensified

With international companies coming into India and local brands rapidly upgrading, customers are now expecting higher accuracy and traceability. That’s why many businesses in India are turning to companies like SIPCON Technologies, which provide solid measurement systems and metrology solutions tailored for Indian manufacturing environments.

How to Calculate CMM Least Count: A Simple Explanation

A common misunderstanding is that least count has a single value, predetermined and written somewhere inside a CMM documentation. This is not the case; least count is derived, and depends on multiple technical factors:

The formula for CMM least count is:

In the simplest terms:

CMM Least Count = Scale Resolution + Probe Resolution + System Internal Noise.

Scale Resolution

Modern CMMs use linear scales (glass, optical, or magnetic).

A typical scale may have:

- 0.5 micron resolution

- 0.1 micron resolution

- 0.01 micron in ultra-high precision system

- This number directly contributes to your least count.

Probe System Resolution

Contemporary coordinate measuring machines(CMMs) utilize linear scales (glass, optical, or magnetic).A proven example of a possible scale will have a resolution of 0.5 micron resolution0.1 micron resolution0.01 micron in ultrahigh precision systems The above resolution directly contributes to your least count.

Environmental Noise & Machine Errors

Factors that affect the measurement capabilities of the CMM include:-

- Temperature variations

- Vibration levels

- Airflow

- Stiffness of the machine

- Probe repeatability

- Noise from electronic signals-

An ideal calibrated CMM is affected by all of these factors

Putting It Together

Sample calculation:-Scale resolution: 0.5 micron-Probe resolution: 0.3 micron-Noise (thermal + mechanical): 0.2 micron-CMM least count = 0.5 + 0.3 + 0.2 = 1.0 micron-Thus, the CMM will be capable of accurately measuring differences down to1 micron.

How Indian Users Should Interpret Least Count

A lot of engineers mistake least count for accuracy. They are related but are not the same.

Least Count = The smallest unit at which we can detect

Accuracy = Overall closeness to the true value.

For instance, a CMM will have an accuracy of ±(2.5 + L/300) microns

But the least count may be 0.5 microns

So, it means,

It could detect a 0.5 micron difference. However, overall accuracy depends on many other factors.

By understanding this, we can avoid unrealistic expectations and misinterpretation of CMM reports.

Role of SIPCON Technologies in Improving Measurement Confidence

SIPCON Technologies has earned a reputation across India for its precision measurement and dimensional inspection systems and has a significant practical role beyond just CMMs.

Here is how SIPCON supports Indian manufacturing teams in real-time application:

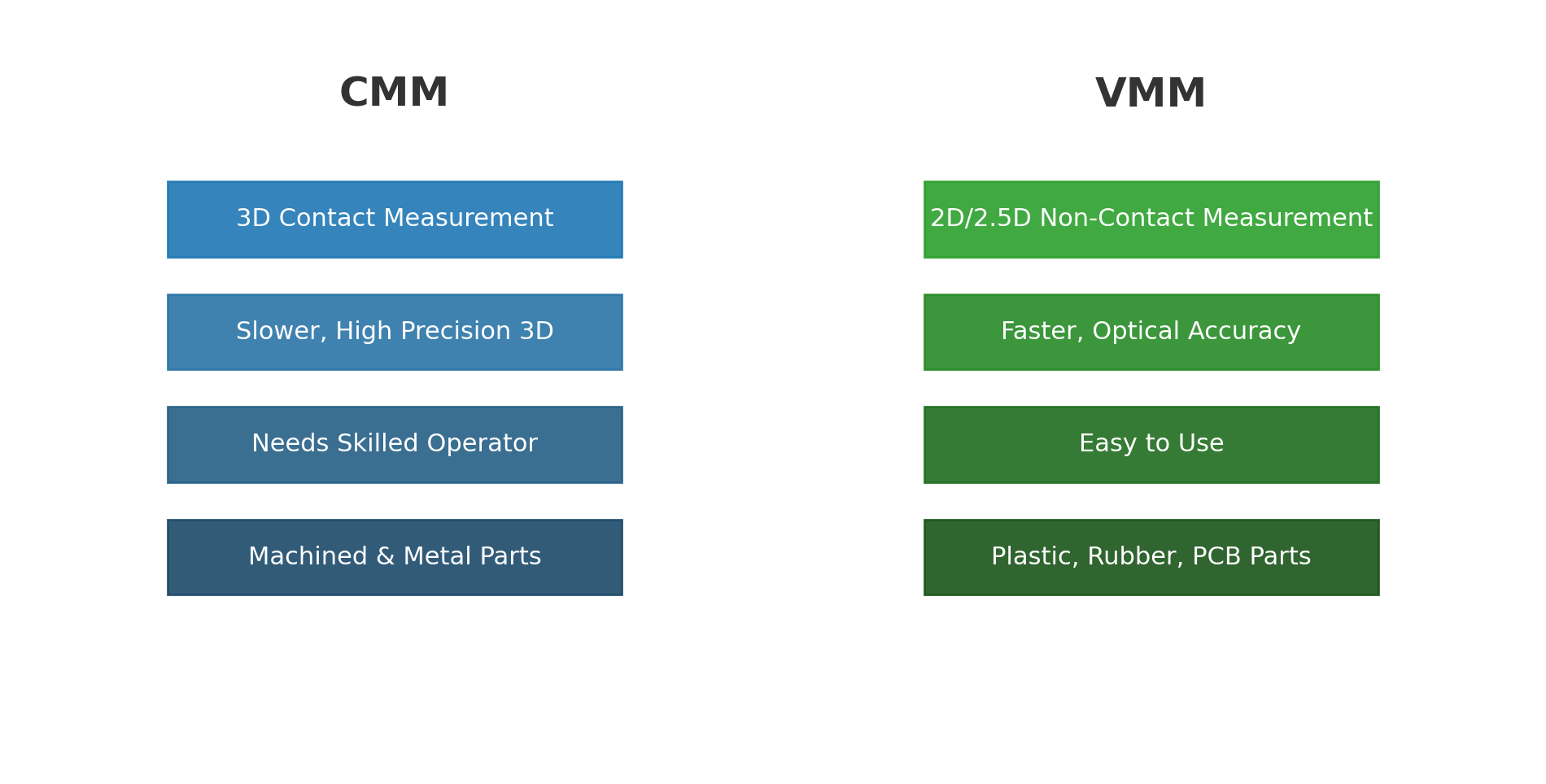

- High-Resolution Vision Measurement Systems

SIPCON’s video measuring machines (VMMs) offer imaging-based inspection systems with micron-level inspection, while avoiding the mechanical complexities of a CMM. This lends itself to:

- Pre-CMM inspection

- Deformation checks

- Tool and die verification

- Small part measurement

Better Understanding of Measurement Principles

Indian operators typically learn CMMs through experience, rather than from a formal course or systematic metrology training. SIPCON provides strong local support to help teams understand the limits of accuracy, scale resolution, implications of least count, etc.

Quicker Dimensional Measurement

In many applications, SIPCON’s systems allow for quick checks and measurements before sending a part to the CMM. This not only reduces load on the metrology team, but it allows for faster inspection and decreases the potential for bottlenecks.

Reliable Reporting and Traceability

Their systems provide automatic reports, which will give confidence to your internal colleagues and external auditors.

As SIPCON continues to grow and gain market share across India, manufacturing teams will have reliable, repetitive, and repeatable tools to help them with measurement.

Do you know you can improve your CMM least count in daily use?

Even the best machine will create poor measurements if the handling is inadequate. Here are some simple ideas that Indian factories could consider implementing: consistent temperature throughout the CMM environment, no dust, less vibration, no unnecessary air flow, orient probes in the same direction for similar inspection work, allow the machine to warm-up before an inspection, calibrate, keep a log, check gauging spheres for wear, and handle stylus with care – even bending a stylus 1 micron will lead to inaccurate measurements. Even though you may be working with a theoretical least count, all of these ideas will help the practical least count and measurement reliability.

Conclusion & CTA

The importance of CMM least count is not just academic, it is a necessary practical key to reliable measurement, proper GD&T interpretation, and customer-acceptable production. In the Indian manufacturing environment, where tolerances are diminishing and customer expectations are greater, knowing how least count is calculated and being able to understand least count helps operators, QA, and management make better decisions on the shop floor.

Manufacturers that add to their CMM workflows high-fidelity tools like the image-based measuring solutions from SIPCON Technologies achieve demonstrably better inspection speed, confidence, and reliability.

If you want to strengthen your dimensional measurement capability, advance real-world least count performance, or enhance your inspection capability with accurate visual metrology equipment:

Please take a look at SIPCON’s measurement and inspection solutions. speak to SIPCON’s technical team for support to improve your quality control processes with dependable metrology solutions, sourced and built in India. Better measurement begins with better knowledge and better equipment. SIPCON assists with both. Strengthen your brand. Speak to our team experts today to get your perfect kit set up for the job. Reach out to us anytime at info@sipconinstrument.com or explore more on our website www.sipconinstrument.com

Phone: +91 82229 29966