Cable Slicers | O-Ring Cable Cutters in Russia: Reliable Cutting Solutions

Cable manufacturing in Russia is changing fast and anyone in the industry can feel it.

With telecom networks expanding, automotive wiring getting more complex, and power infrastructure constantly upgrading, manufacturers are being pushed toward higher precision every day.

And in this kind of environment, even a single cable cut isn’t a small detail anymore.

It affects everything that happens next.

In cable manufacturing, every cut is a decision point where precision either protects performance or quietly undermines it.

Cable slicers, O-ring cable cutters and compact cable O-ring cutters, once considered basic tools, are now essential instruments that support accuracy, safety and repeatability across Russian production lines.

Why Cable Cutting Tools Are Important in Russia?

Modern Russian factories operate under stricter quality controls and rising production expectations. Manual cutting techniques cannot consistently deliver the accuracy required for telecom fiber preparation, automotive harness assembly or high voltage cable fabrication.

A study published in IEEE Access Journal, found that many wiring defects originate from inconsistencies introduced during the earliest stages of cable preparation. Russian plants transitioning to semi-automatic systems experience similar challenges. A poorly scored jacket or uneven edge can slow connector seating, disrupt automated crimping and lead to rework that interrupts production flow.

Reliable cutting tools help reduce:

- Conductor surface damage

- Unpredictable strip lengths

- Jacket deformation that affects fit

- Scrap rates and inspection failures

Factories work with copper, aluminum, fiber or multistrand cable types often find that better cutting tools significantly improve line stability.

Cable Slicers: Efficient and Accurate Cutting

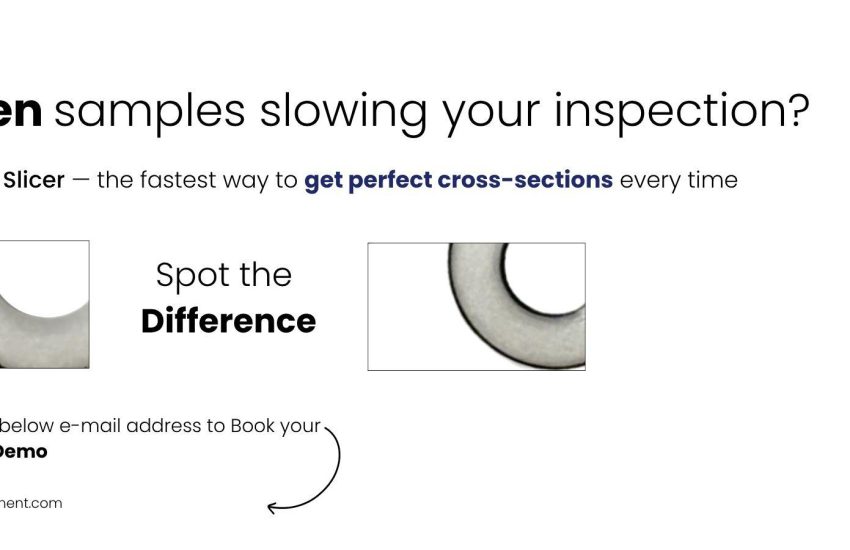

A cable slicer is designed to produce a clean, round cut. However, even minor irregularities can influence connector seating or alter how insulation behaves in later stages of assembly.

Key strengths of cable slicers include:

- Dependable cutting surfaces

- Reduced material wastage

- Longer blade life using hardened or carbide materials

- Smoother workflow due to fewer interruptions

Blade integrity is especially important. Hardened steel and carbide blades maintain their sharpness longer, providing predictable performance across multiple cable types within a single shift.

Cable slicers are widely used in Russia across electronics assembly lines, telecom preparation units and power cable workshops. Several cable slicer manufacturers now offer compact models suitable for mid-sized factories seeking consistent cuts without full automation.

O-Ring Cable Cutters: Specialized for Precision

An O-ring cable cutter produces a controlled circular score around the jacket. This technique is helpful when a partial strip is required without disturbing the inner layers.

Industry studies and widely accepted manufacturing guidelines show that controlled circular scoring provides more stable and repeatable results than manual knife techniques, particularly during high-volume harness production. Even small inconsistencies in jacket removal can affect connector fit and long-term reliability.

Why O-ring cutters matter?

- Uniform circular scoring

- Reduced tearing on soft insulation

- Less operator-based variation

- Compatibility with semi-automated stripping stations

Telecom facilities depend on O-ring cutters for fiber jacket preparation, while automotive suppliers rely on them to maintain tight tolerances in wiring harnesses. Electronics manufacturers value the control they offer on delicate, flexible cables.

Cable O Ring Cutters: Industrial Applications

Cable O-ring cutters are widely used in Russian wiring workshops for compact tools designed for controlled jacket scoring. Their value is clear in industries where minor deviations may create major downstream issues.

Key applications include:

- Telecom and fiber optics for preparing jackets before connector termination.

- High voltage cable preparation where inner layers must remain undisturbed

- Automotive and aerospace wiring where precision affects electrical reliability

- Electronics and consumer goods where small flexible cables require careful handling

Many facilities operating across multiple shifts note that using a stable O-ring cutter helps reduce rework and maintain consistent production schedules.

Choosing the Right Cable Cutter in Russia

Selecting the right cutting tool depends on the type of cables produced and the factory’s workflow. Russian manufacturers typically evaluate several practical criteria before making a decision.

Important considerations include:

- Cutting diameter range for different cable families

- Blade quality, as hardened steel and carbide maintain accuracy longer

- Depth control to protect internal conductors

- Ease of handling during extended shifts

- After-sales support, especially for factories outside major industrial regions

- Manufacturer stability for long-term reliability

Workshops often perform small batch trials to observe how a cutter behaves under real operating conditions.

Future of Cable Cutting Technology in Russia:

Cable manufacturing in Russia is gradually moving towards higher automation and integrated quality monitoring systems.

Notable trends include:

- Introduction of robotic cutting modules for repetitive tasks

- Hybrid manual digital tools with improved alignment guidance

- Increased focus on scrap reduction as material costs fluctuate

These developments indicate that cutting tools will become more connected to data tracking and quality dashboards across Russian plants.

Reliable Cable Cutting Solutions for Russian Industries

The quality of a cable cut may appear minor, yet it directly shapes termination strength, electrical stability and long-term product performance. As Russian manufacturers continue expanding in telecom, energy and automotive sectors, dependable cutting tools are essential for ensuring consistent production.

Whether the team member is prepping fiber for a splice or putting together a complex wiring harness, the right cutting tool makes the entire process easier. And in an industry built on connection and continuity, it’s often the smallest cut that carries the most responsibility.

In an industry built on connection and continuity, even the smallest cut often carries the greatest responsibility.

We will be happy to support your production and quality goals. Do get in touch with us –

export@sipconinstrument.com

OR visit us at: https://www.sipconinstrument.com/contact.php