Carbon Black Dispersion Tester: A Practical Quality Check for Polymer Performance

In polymer manufacturing, many failures do not appear immediately. Products often pass routine inspections and still fail years later in real operating conditions. In the USA market, where cables, pipes and plastic components are expected to last for decades, such failures lead to high replacement costs and loss of trust.

The most common and often overlooked cause behind long term problems is poor carbon black dispersion. This is why carbon black dispersion testing is now considered an essential quality control process, not just an optional check.

Why Carbon Black Dispersion Testing Matters

Carbon black improves strength, UV resistance & durability in polymers. These benefits depend entirely on how evenly the material is dispersed during processing.

When dispersion is poor, carbon black forms clusters inside the polymer. These clusters create weak zones that respond differently to heat, stress, and aging. The material may still look acceptable initially, but degradation starts internally and appears much later during service.

Dispersion testing helps manufacturers identify these risks early, before products reach customers or long term installations.

What a Carbon Black Dispersion Tester Reveals

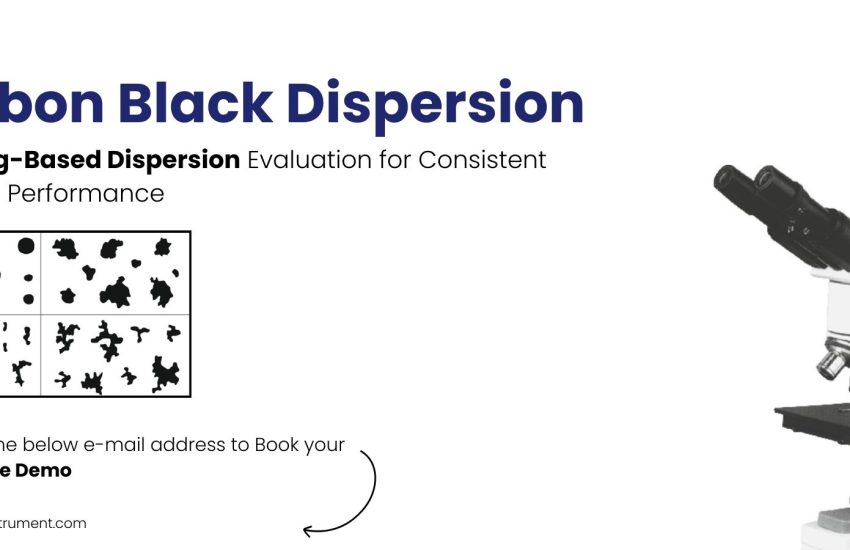

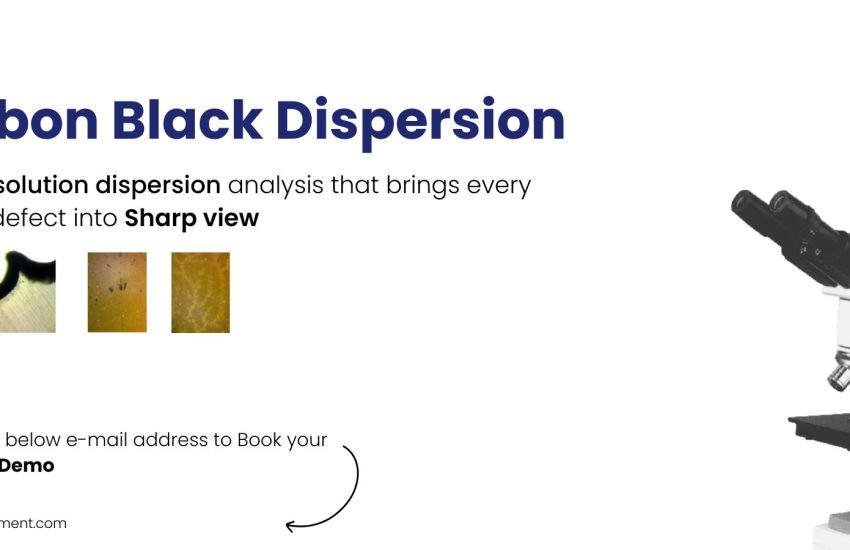

A carbon black dispersion tester shows how carbon black is distributed inside a polymer sample. Thin sections are examined under a microscope to check whether the material is uniform or clustered.

Good dispersion appears smooth and even. Poor dispersion shows visible agglomerates. These patterns provide clear feedback on mixing quality, processing conditions, and material handling.

Because standardized testing methods are used, results remain consistent and reliable across batches and audits.

Importance in Cable and Wire Manufacturing

Cables installed in the U.S. are expected to operate reliably for many years without maintenance. Carbon black is added to insulation to protect against UV radiation and environmental stress.

If dispersion is uneven, insulation degrades faster in certain areas. Weak spots form gradually and expand over time. These issues often go unnoticed during routine electrical testing.

Dispersion testing allows manufacturers to detect such internal risks early & correct processing issues before large scale production or shipment.

Use Across Polymer Industries in the USA

Besides cables, dispersion testing is also widely used in masterbatch production, film and sheet processing, and plastic pipe manufacturing. Consistent product strength, good surface finish, and long-term stability depend directly on uniform dispersion.

Furthermore, dispersion testing is employed in testing facilities and research laboratories, where the behavior of different formulations and materials is studied and evaluated under controlled conditions.

What Makes a Reliable Dispersion Tester

A reliable carbon black dispersion tester must provide clear imaging, stable operation and repeatable results. Good optics help distinguish true dispersion from preparation artifacts, while mechanical stability ensures consistent evaluation.

Compliance with recognized standards allows test results to be accepted by customers and regulatory bodies. Durability is important, as dispersion testing is often performed daily in quality control labs.

Manual Testing and Digital Dispersion Analysis

Traditional dispersion testing relies on visual evaluation by trained operators. While effective, it can vary between operators.

Digital carbon dispersion analyzers reduce subjectivity by using imaging software to standardize grading. These systems are preferred in high volume manufacturing environments where speed & consistency are critical.

Supporting Role of Die Inspection

Dispersion quality is influenced not only by mixing but also by extrusion hardware. Worn or damaged dies can disturb material flow and affect dispersion.

Routine die inspection helps identify such issues early. When combined with dispersion testing, it strengthens overall process control and product consistency.

Why Manufacturers Work with Sipcon Instrument

Manufacturers across the U.S. rely on Sipcon Instrument for dependable carbon black dispersion testing solutions. Sipcon systems are designed for daily laboratory use, offering stable performance and compliance with international standards.

Along with equipment, Sipcon provides technical guidance and support, helping quality teams implement dispersion testing effectively within existing workflows.

FAQs

Q:1 What exactly does a carbon black dispersion tester measure?

In simple terms, this tester checks whether the carbon black is properly & evenly dispersed within the polymer. While the formulation might look perfect on paper, the actual processing can leave small clumps of carbon black within the material. The dispersion tester clearly reveals these clumps, which are typically invisible to the naked eye & undetectable through standard routine testing.

Q:2 Why is carbon black dispersion testing often overlooked during production?

Most manufacturing plants focus primarily on output, dimensions and electrical values, as these parameters can be measured immediately. In contrast, the effects of poor carbon black dispersion are not immediately apparent. It’s a problem that manifests gradually over time.

This is why it’s often overlooked during the production stage. The real trouble becomes evident only after the product is already in use and by then, it is usually too late to make corrections.

Q:3 Does poor dispersion always lead to immediate product failure?

No. This is the riskiest part. The impact of poor dispersion is slow. The material initially performs well, then local weak spots begin to form. With heat, UV exposure and load, these spots grow. Failure seems sudden, but the root cause lies in the manufacturing stage.

Q:4 How dependable are the results from a carbon black dispersion test?

If the sample preparation and testing method are followed correctly, the results are quite dependable. The advantage of dispersion testing is that it reveals the reality inside the material, not just the surface behavior. This is why quality teams use this test for process control, not just for rejection.

Q:5 Is dispersion testing more important for cables than other plastic products?

Dispersion testing becomes more critical for cables because their replacement is not easy. Once installed, replacing a cable is costly and risky. If the dispersion within the insulation is poor, the problem will surface years later. Therefore, for cable manufacturers, dispersion testing acts as a long-term safety check.

Q:6 What is the difference between manual dispersion testing and digital analysis?

Manual testing depends on experienced operators. Experienced people can make good judgments, but variations can occur. Digital dispersion analysis uses imaging and software, which standardizes the interpretation. Digital systems are more practical for high-volume plants, especially when comparing data from multiple shifts.

Q:7 Can dispersion testing systems be adjusted for different materials?

Different polymers exhibit different behaviors. The testing system can be configured according to the heating stage, analysis technique and microscope optics. This versatility allows laboratories to develop testing protocols that closely match their actual production materials.

Q:8 Why do many labs prefer systems from Sipcon Instrument?

Labs generally prefer equipment that remains stable in daily use. Sipcon Instrument’s dispersion testers follow industry standards and are practical for routine lab work. Additionally, the availability of technical support and application guidance ensures that quality teams don’t face problems during implementation.

Final Note

Carbon black dispersion testing is often underestimated because its impact is not immediate. A product with poor dispersion may pass inspections today and still fail years later under real operating conditions. By the time such failures appear, the cost of correction is usually far greater than the cost of prevention.

For polymer manufacturers in the United States, dispersion testing acts as an early warning system. It helps teams understand what is happening inside the material, long before cracks, aging or performance loss become visible. When dispersion is controlled at the manufacturing stage, products age more predictably, quality variations reduce, and long-term reliability improves.

In practical terms, carbon black dispersion testing is not just about meeting specifications. It is about protecting product performance over its entire service life.

Practical Guidance from Sipcon Instrument

If you are evaluating your current dispersion testing practices or planning to upgrade laboratory equipment, Sipcon Instrument offers application-focused support based on real manufacturing conditions. Their team helps quality and process engineers select suitable configurations based on material type, testing frequency, and reporting needs.

For technical discussions, system details, or quotation support, you can contact Sipcon Instrument directly at

✉️: export@sipconinstrument.com

📲: +1 (262)391-4785

📍: 260 North Beaumont Ave Brookfield Wisconsin 53005 USA