Are You Searching for up-to-date methods to test carbon black dispersion for quality control uses?

Ever thought of carbon black as a material that is able to strengthen the polymer-based one by making it more durable, resistant to UV radiation, conductive, and of higher structural integrity? However, these benefits can only be retained if the carbon black is evenly dispersed in the polymer matrix.

That is the reason why the carbon dispersion test ranks as the first instrument in the portfolio of many quality control laboratories. Even high-quality materials have the potential to fail if they are not properly dispersed.

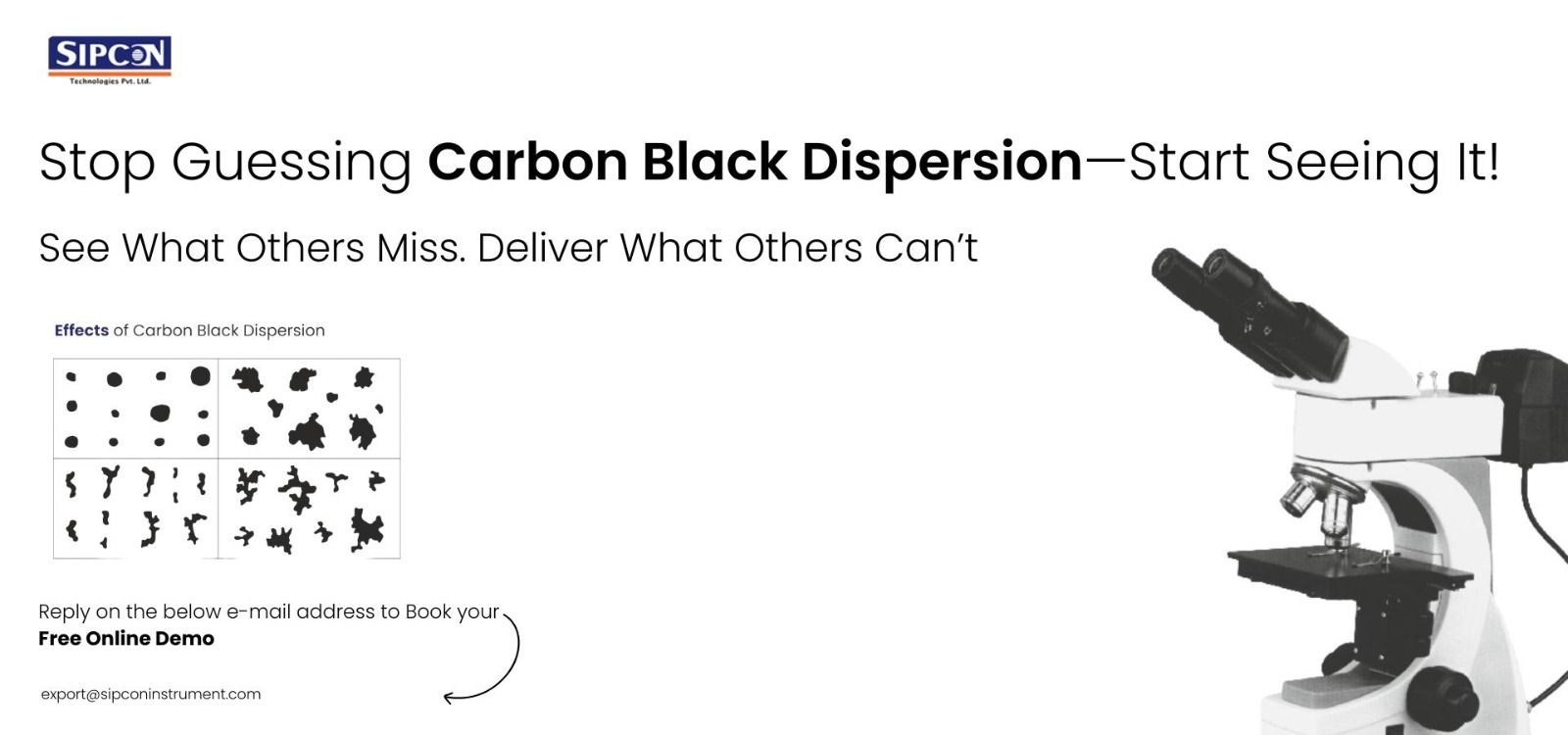

Poor dispersion may lead to:

- Cracks or weak spots in the material

- Poor UV resistance

- Reduced mechanical strength

- Uneven surface finish

- Electrical inconsistency

- Higher rejection rates during QA testing

Dispersion testing remains a non-negotiable quality step across industries related to cables to automotive,

Why Testing for Carbon Black Dispersion Is Essential

Industries that rely heavily on polymer performance conduct carbon dispersion tests to ensure:

- Strong mechanical properties

- Weather and UV resistance

- Long-term product stability

- Consistent surface appearance

- Compliance with global standards

- Sectors that depend on accurate dispersion testing include:

- Cable and wire manufacturers

- Pipe and extrusion units

- Film and sheet processors

- Masterbatch and compounding units

- Research laboratories

Uniform carbon black dispersion is a direct indicator of material performance. Even small variations can affect the lifespan and safety of the final product.

Carbon Black Dispersion Tester: Features & Technical Strengths

A high-quality carbon black dispersion tester helps technicians visually examine the distribution of carbon black within a sample using microscopic evaluation. The device plays a vital role in identifying whether a polymer sample meets international quality standards.

Key Features

✔ High-Clarity Microscopy

Allows clear visual grading of dispersed carbon particles.

✔ Uniform Sample Heating

Ensures proper melting and flattening during sample preparation.

✔ Heavy, Vibration-Free Construction

Provides a stable base for sharp, blur-free microscopic evaluation.

✔ Standards Compliance

Supports ASTM and ISO requirements for accurate dispersion assessment.

✔ Long Operational Life

As its built with sturdy components, the tester is widely valued for its simplicity, consistency, and low maintenance—making it ideal for labs handling multiple batches every day.

Carbon Black Dispersion Tester Pricing Insights

Procurement teams often search for competitive rates and configuration options before choosing the right dispersion testing system. One of the most popular queries is:

“Carbon black dispersion tester Price in Saudi Arabia”

The cost typically depends on:

- Model type (manual/semi-automatic/digital)

- Microscope configuration

- Stage lighting options

- Optional analysis software

- Installation and training preferences

Price variations ensure laboratories can select a configuration that fits their workflow, testing volume, and reporting requirements.

Carbon Dispersion Analyzer: Faster, Digital, High-Consistency Testing

Modern manufacturing units with high output volumes often shift toward automated solutions. A carbon dispersion analyzer removes operator subjectivity and speeds up the evaluation process.

Advantages of Digital Analysis:

- Automated imaging & grading

- Standardized interpretation

- Faster reporting

- Zero operator bias

- Clean and exportable test documentation

These systems are ideal for high-volume plants where accuracy and speed are equally critical.

Die Inspection Microscope: Ensuring Die Health & Product Consistency

Extrusion dies directly influence material output. Even minor defects can disrupt dimensions and surface uniformity. A die inspection microscope allows technicians to examine the die condition before production issues occur.

Benefits:

- Sharp magnification for defect identification

- Quick detection of cracks, wear, or buildup

- Sturdy, stable microscope frame

- Easy adjustment for fast inspection cycles

Using die inspection regularly reduces downtime, improves dimensional accuracy, and enhances product consistency.

These testing systems are used across a wide range of application areas:

- Plastic processing

- Wire & cable manufacturing

- Extrusion and pipe industries

- Petrochemical companies

- Automotive component manufacturers

- Testing laboratories and universities

Each sector values accurate dispersion analysis as a foundation for good material performance.

What Makes These Testing Systems Stand Out?

- High Accuracy & Reliability

Quality optics and strong mechanical design ensure repeatable test results. - Invented for Heavy-Duty usage

It’s Suitable for labs running multiple inspections throughout the day. - Simple & Technician-Friendly

Smooth operation, clear results, and minimal maintenance. - Customizable Options

Labs can choose microscopes, lighting modules, or digital add-ons based on their needs. - Support & Service

To ensure uninterrupted use, Manufacturers provide full support in installation assistance, training, and after-sales support

Product / Too Purpose Key Benefit Carbon Black Dispersion Tester Visual carbon dispersion evaluation. Accurate, stable, and standard-compliant Carbon Dispersion Analyzer Digital automated dispersion grading Faster testing + zero operator subjectivity Die Inspection Microscope Die surface and defect inspection Prevents defects; ensures die performance.

FAQ

Q1. To whom to contact for Carbon Black Dispersion Tester manufacturers in Saudi Arabia?

For manufacturers in Saudi Arabia, Sipcon Instruments can be contacted as they are widely recognized for supplying reliable and high-quality dispersion testing systems that meet international standards.

Q2. How accurate is the carbon dispersion test?

With the right equipment, the test provides highly consistent and repeatable results, helping teams identify even minor dispersion issues.

Q3. What affects the Carbon black dispersion tester Price in Saudi Arabia?

Pricing depends on model type, microscope specification, and digital enhancement options. Sipcon Instruments offers transparent quotations and guidance to help labs choose the right fit.

Q4. Can these instruments be customized?

Yes. Sipcon Instruments provides configuration flexibility in microscopes, heating systems, and software modules.

To explore certified testing instruments—including dispersion testers, analyzers, and die inspection microscopes—visit:

👉 www.sipconinstrument.com/sa/