CMM Machine: The Ultimate Guide to Coordinate Measuring Machines in 2026

A coordinate measuring machine, also known as a CMM Machine, is an advanced instrument that accurately measures the physical and geometric dimensions of manufactured parts. In modern manufacturing industries, CMM machines have become a key tool for part inspection and verification.

The advantages of a CMM go beyond just accurate measurement. The real benefit lies in ensuring that your parts conform to design specifications, reducing scrap and rework, and enabling the measurement of complex shapes that would be difficult to measure with traditional gauges.

In this blog, we will provide you with comprehensive information about CMM machines – how they work, the different types available, their applications in various industries, accuracy standards, and even pricing and purchasing tips.

How a CMM Machine Works

Essentially, a CMM machine measures the physical characteristics of an object in three dimensions — X (length), Y (width), and Z (height) — using the principles of coordinate geometry. The measurement is carried out by a sensing probe, which moves in a deliberate and precise manner and records different points on the surface of the object.

When a part is placed on the granite table of a CMM, the operator or controller starts a measurement routine. The probe touches or scans the critical areas of the part. When the probe interacts with the surface, the machine captures positional coordinates relative to a fixed reference point.

These thousands of points are then processed by powerful software to generate precise dimensional data. This data ensures that the measurements of the part match the original design or CAD model.

Depending on the model, the probe may:

- Physically contact the part (touch trigger or scanning contact probes),

- Use a laser or optical sensor (non‑contact scanning), or

- Combine multiple sensor technologies to capture rich dimensional data.

This measured data is compared to the nominal CAD model and engineering specifications—such as tolerances defined by GD&T. The software calculates the differences between the two and generates inspection reports based on these differences to support quality-related decisions.

Types of CMM Machines and Their Uses

CMM machines are not one‑size‑fits‑all. Different types exist to address specific measurement challenges and part geometries. While the core principle remains consistent, each type offers unique advantages based on how its structure is arranged.

1. Bridge CMM Machines

Bridge CMMs are the most commonly used and recognized form. They feature a rigid horizontal beam supported by two vertical columns, forming a “bridge.” The probe moves along this bridge structure, allowing precise X, Y, and Z motion.

Bridge CMM machines are most commonly used for measuring medium to large sized parts. They are widely trusted across general manufacturing, automotive & aerospace industries. Thanks to their rigid construction and high precision air bearing system, these machines are well suited for inspecting parts with tight and critical tolerances, delivering consistently accurate and reliable results.

2. Gantry CMM Machines

Gantry CMM machines are essentially scaled-up versions of bridge CMMs, built specifically for inspecting very large and heavy components. Their robust structure moves over the workpiece, offering excellent stability when measuring large assemblies such as aircraft parts, ship components, and heavy machinery fixtures.

This design allows gantry CMMs to maintain high accuracy across large measuring volumes, though they typically require considerable floor space and a higher initial

3. Cantilever CMM Machines

Cantilever CMMs support the bridge from one side only, offering easier access to the measurement table from three directions. This is especially useful for smaller or medium components where workspace accessibility matters.

While cantilever systems are less rigid compared to full bridge CMMs, they are great for shop‑floor use where ease of loading and unloading parts is a priority.

4. Horizontal Arm CMM Machines

Horizontal arm CMMs have their measuring arm extended horizontally, which makes them suitable for very long and flat parts such as car body panels or sheet metal assemblies.

They provide excellent reach and flexibility, though they tend to be less accurate than bridge or gantry types due to the extended arm structure.

5. Portable and Articulated‑Arm CMMs

When it is difficult to move large parts to the machine during field inspections, portable arm CMMs and handheld laser or optical scanners come in very handy. These have articulated joints, allowing the operator to easily move the probe around the part by hand.

Although they are not as accurate as fixed systems, their ease of use and portability make them an excellent option for onsite measurements.

Key Components Inside a CMM Machine

A modern CMM machine consists of several critical parts that work in concert to deliver accurate measurement results:

- Granite Base and Table: Provides a stable, vibration resistant platform that remains flat over long periods and minimizes thermal expansion.

- Bridge or Frame Structure: Supports and guides the movement of the probe in 3D space.

- Probing System: Can be contact touch probes, scanning probes, laser or optical sensors and multi sensor arrays.

- Axis Motion System: High precision linear guides or air bearings that control the movement of the probe.

- Controller and Software: The brain of the system, which records point data, processes it against CAD models, and generates inspection reports.

- Accessories: Fixtures, rotary tables and tool changers that expand functionality & ease complex measurement tasks.

Accuracy, Standards and Practical Interpretation

One of the most critical concerns for engineers and quality professionals is how accurate a CMM machine really is. Accuracy in CMMs is governed by both machine design and industry standards such as ISO 10360.

In simple terms, accuracy indicates how well the CMM can measure a point relative to its “true” position. Most modern touch probe CMMs can achieve micron‑level repeatability, meaning that repetitive measurements will vary only fractions of a thousandth of a millimeter.

These standards help manufacturers clearly state the performance level their CMM machines can deliver, and provide users with a basis for easily comparing different CMM machines.

The accuracy you actually achieve depends on several different factors:

- Temperature stability in the workspace

- Vibration isolation

- Probe type and calibration

- Part fixturing and setup

- Measurement strategy chosen in software

Why CMM Machines Are Important in Industry Applications

CMM machines are used in many different industries where accuracy in measurement, consistent results and adherence to quality standards are essential.

1. Automotive Industry

Automotive companies use CMMs to verify critical dimensions that affect vehicle performance & safety. In today’s world, where EVs and autonomous vehicles demand even greater precision, CMM inspection ensures that parts meet specified tolerances and reduces the need for costly rework.

2. Aerospace and Defense

Aerospace components require very tight tolerances for both safety and performance. In this environment, CMM machines are used as a standard inspection tool, fully supported by aerospace quality systems and certification processes.

3. Medical Devices

Medical devices often feature micro features and complex geometries. CMMs with non contact probing ensure that these parts meet stringent regulatory standards such as those set by the FDA & ISO 13485, thereby reducing risks to patients and guaranteeing product reliability.

4. Electronics & Precision Manufacturing

From semiconductor wafers to micro mechanical parts, electronics manufacturing involves parts that push the limits of human inspection. Multi sensor CMMs with optical and laser probes deliver high resolution data for tiny and intricate features.

What to Expect in the 2026 Pricing Guide

Here is some general information about the factors that affect the price:

- Machine Size: Larger measuring volumes cost more.

- Accuracy Class: Higher repeatability and tighter tolerance systems are priced higher.

- Probe Technology: Laser and multi‑sensor systems add premium over basic touch probes.

- Automation: CNC motion and software workflows increase overall cost.

- Brand & Support: Global brands with strong after‑sales support may carry a premium.

In the USA, entry‑level shop CMMs can start in the mid‑five figures, while high‑precision multi‑sensor systems used in aerospace or advanced automotive applications can reach six figures and beyond.

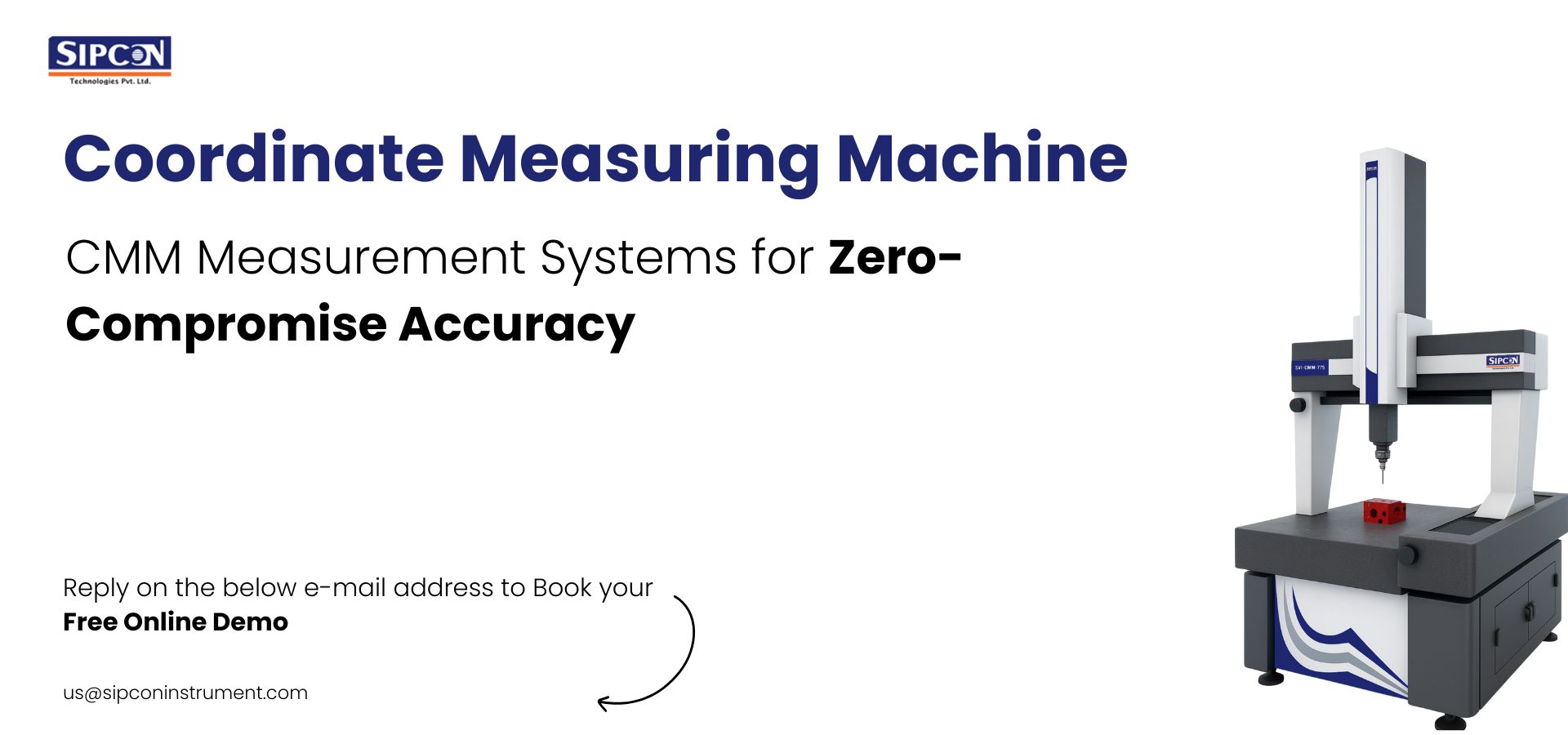

How Sipcon’s CMM Machines Fit Into This Landscape

SIPCON’s CMM machines are designed with international standards in mind, ensuring superior accuracy and reliable performance over the long term. They feature a robust granite structure and air bearings, which make the machines stable and durable.

Compatible with premium probing systems such as Renishaw’s touch and scanning probes, these machines can be used in a wide range of applications, including automotive, aerospace, electrical and educational sectors.

Whether you require manual operation or full CNC automation, Sipcon’s CMM solutions offer flexibility, precise measurements and seamless integration with modern 3D inspection software, along with clear reporting that supports quality and engineering processes.

CMM Machines: Frequently Asked Questions

Q1. Do all CMM machines use contact probes?

No. While traditional contact probes are common, modern machines also employ non contact laser & optical scanning systems for faster high density measurement and delicate surfaces.

Q2. Can CMM machines be automated?

Yes, CNC CMM machines perform measurements automatically. This reduces operator error & speeds up the process while ensuring consistent results every time.

Q3. Which industries benefit the most from CMM machines?

Industries where dimensional accuracy is critical, For example automotive, aerospace, medical devices, electronics, shipbuilding & precision engineering.

Q4. What software do CMM machines use?

Most advanced systems include integrated metrology software that compares measurement data to CAD models, analyzes tolerances & generates inspection reports.

Conclusion

A CMM machine is an indispensable tool for precision metrology – It bridges the gap between design intent and manufacturing reality. From verifying dimensional compliance to performing detailed geometric analysis, CMM machines play a crucial role in industries

Take the Next Step in Precision

If you want to improve your quality inspection, Sipcon’s precision CMM machines offer reliable and accurate solutions. Whether you are in the automotive, aerospace, medical & general manufacturing industry, our expert team will help you choose the right system.

➡ ️ Contact us today for a quotation and expert advice.

Visit us: https://www.sipconinstrument.com/us/

Phone number: +1 (262)391-4785

Mail us: us@sipconinstrument.com

Address: 260 North Beaumont Ave Brookfield, Wisconsin 53005 USA

Let us help you achieve zero rejection and maximum precision in every part you measure.