Drawing Die Measurement in Australia – Complete Guide

In Australia’s growing manufacturing sector, quality and precision have never been more important. From the cables used in construction to the rods and wires powering the automotive and mining industries, even the smallest inconsistency can cause big problems. That is why drawing die measurement has become an essential part of modern production.

What is Drawing Die Measurement?

A drawing die is the tool that shapes wires, rods, and tubes. If a die is uneven, worn, or not polished properly, even the smallest flaw can lead to defects in the finished product. Drawing die measurement is the careful process of checking and verifying these dies to make sure they are accurate, consistent, and ready for use. This step is crucial for manufacturers who want to maintain high-quality production and avoid costly mistakes.

Why It Matters in Wire, Cable, and Metal Industries

In industries where safety, durability, and performance are critical such as automotive, construction, and energy—drawing die measurement is essential. Accurate measurements ensure that every wire, rod, or tube meets strict Australian and international quality standards. It also helps manufacturers cut down on material waste, prevent production errors, and guarantee that products perform reliably when they reach customers. Simply put, well-measured dies are the backbone of consistent, high-quality output.

How Measurement Ensures Precision and Quality

Modern drawing die inspections use specialised machines and advanced systems to catch even the smallest deviations before they affect production. These tools can spot problems like uneven surfaces, incorrect angles, or subtle tapering that might otherwise go unnoticed, ensuring that every part meets the highest standards.

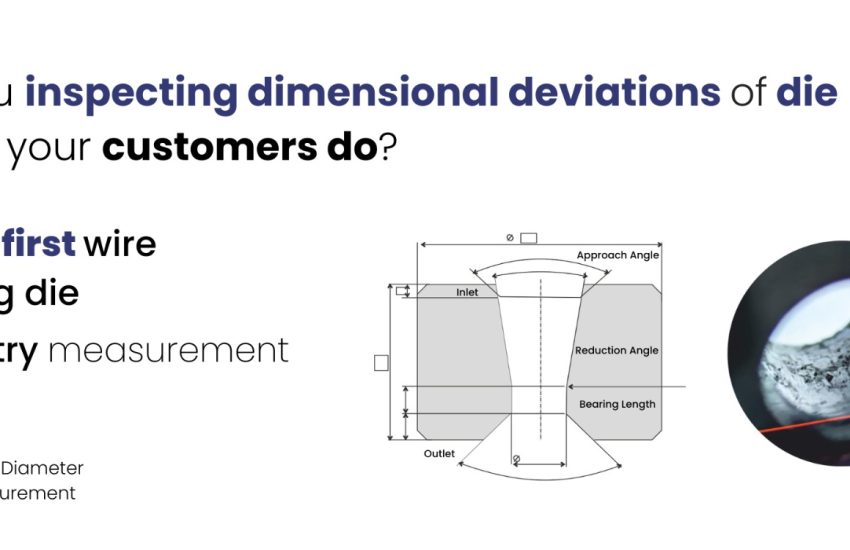

Understanding Drawing Die Geometry Measurement

- Why Geometry Matters in Dies?

The shape and internal geometry of a drawing die play a huge role in determining the quality of the final product. Even a tiny error in the angle, taper, or profile can affect the strength, durability, and overall performance of rods, wires, or cables. When the die is perfectly shaped, every part produced meets design specifications and performs reliably in real-world conditions. In short, accurate geometry is the foundation of consistent, high-quality manufacturing. - Parameters Checked in Australian Manufacturing companies

In Australia, manufacturers rely on drawing die geometry machines to check every critical aspect of a die. These machines inspect parameters like:

Width – ensuring the die produces the correct dimensions

Surface Evenness – detecting any irregularities that could affect the final product

Taper – verifying the gradual narrowing is precise for proper shaping

Polish – checking for smooth surfaces to reduce friction and wear

Symmetry – confirming the die is perfectly balanced for consistent output

By monitoring these parameters, manufacturers can maintain consistency across production runs, reduce material waste, and ensure that every rod, wire, or cable leaving the factory meets the highest quality standards.

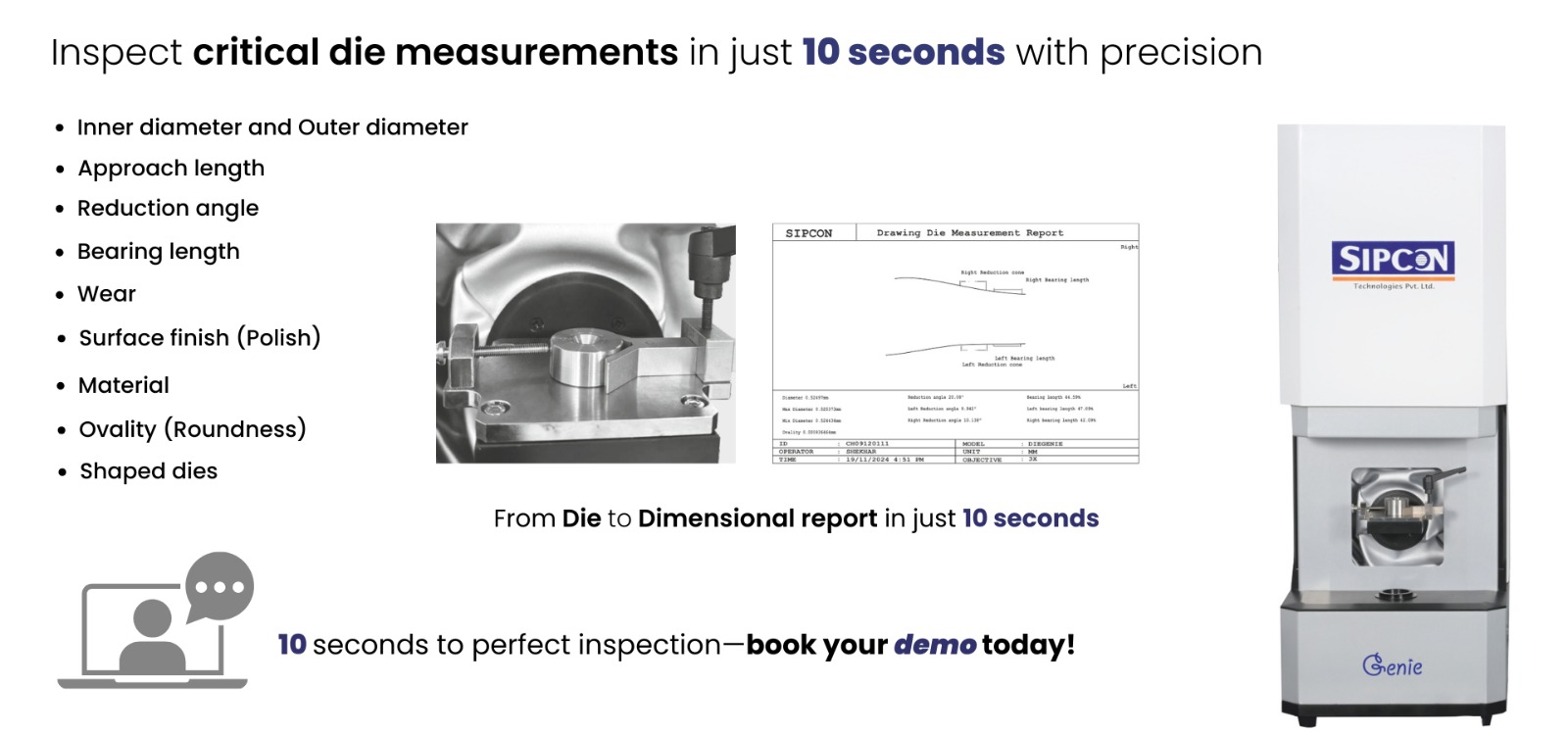

Drawing Die Measurement Machines & Systems

- Drawing Die Measurement Machine

A drawing die measurement machine is designed to record dimensions and highlight even the smallest irregularities. With the help of smart sensors and software, these machines reduce human mistakes and deliver reliable, consistent results every time.

- Automated Drawing Die Measurement Systems

More factories in Australia are turning to automation. These systems use smart software with accurate measurement tools to speed up inspections and keep results consistent. It is part of a bigger shift in manufacturing towards smarter, more efficient ways of working.

Role of a Drawing Die Inspector

- Functions and Responsibilities

No matter how advanced the machines are, they cannot replace the knowledge of an experienced drawing die inspector. These systems combine intelligent software with precise measurement tools to make inspections faster and results more consistent. They are part of a broader move in manufacturing toward smarter, more efficient ways of working. - Use of Microscopes and Measurement Tools

In Australia, inspectors rely on tools such as microscopes and optical comparators to check for wear, catch even the smallest defects, and confirm the quality of dies. Their practical experience works alongside the precision of these machines, giving extra assurance that every part leaving the production line meets top-quality standards.

Applications of Drawing Die Measurement in Australia

- Cable and Wire Manufacturing

From household wiring to large-scale power cables, drawing die measurement ensures every cable and wire meets strict quality and safety standards. It helps manufacturers maintain consistent dimensions and avoid defects that could cause failures later. - Mobility Parts

In Australia’s automotive sector, precision-shaped rods and wires are critical for making stronger, more reliable parts. Using drawing die measurement helps manufacturers maintain exact dimensions, improve performance, and reduce the risk of part failures. - Precision Engineering Industries

Sectors like aerospace and defence demand the highest levels of accuracy. Here, drawing die geometry machines and 3D profile measurement systems play a key role in ensuring components meet international quality standards, compliance requirements, and performance expectations.

How to Choose the Right Drawing Die Measurement System in Australia

- Accuracy and software compatibility

Manufacturers should focus on machines that provide accurate results that gives 3D profiling capabilities, and work seamlessly with their existing software for easy data reporting.

- Supplier and things manufacturers should look at

Working with local suppliers usually means timely services and easier maintenance, while overseas systems can give more features. Australian manufacturers can make good choices that ensure lasting performance and dependability.

Conclusion: Future of Drawing Die Inspection in Australia

For manufacturers in Australia, precision is not just a goal it is the key to success. By using drawing die measurement machines and modern inspection systems, businesses can reduce errors, work more efficiently, and make sure every product leaving the factory meets the highest quality standards.”

📩 Contact us: export@sipconinstrument.com