Drawing Die Measurement in Australia – Complete Guide

When it comes to Australia’s manufacturing sector, quality and accuracy have never been so crucial. Whether in the cables used for construction or the rods and wires that underpin automotive and mining, even a slight blemish can lead to big problems. That is why measuring of the drawing die has become a necessity for the today’s production.

What is Drawing Die Measurement?

A wire drawing die is a tool used in a wire drawing machine to shape wires, rods, and tubes. Die Even a minute defect in the shape or finalization of the die will cause defective products. Die measurement Every die is individually checked to ensure each die measured for accuracy and conformity. Especially if you are an Australia manufacturer, it is crucial to the completion of decreasing reworks and preventing manufacturing mistakes because your stuff can be great expensive.

Why Does It Matters in Wire, Cable, and Metal Industries?

In critical performance, safety and operational industries (automotive, construction, etc.) if your product is not a bit of metal skeleton that is engineering type applications If you measures drawing dies properly then it gives you confidence that for every wire/rod/cable meterage 1000 years ago was produced by me (or vendor of aforementioned product) of great worth of steel on hand Mine complies with Australia’s universal and globally accepted. You will go with good measuring practices to minimize material waster, prevent mistakes that are expensive to either fix or not fix, ensuring the things you make meet its performance characteristics should define when bought by your client.

How Measurement Certifies Precision and Quality

Inspections are now done with drawing die measuring machines and techniques too (and I know they shiver), even small scuff in their product are not getting by before it is run again. Precision measuring. Premium equipment can easily detect irregularity on a part, improper angles, even the most minute taper that would otherwise go unnoticed and brings all parts up to the peak performance.

Understanding Drawing Die Geometry Measurement

Why Geometry Matters in Dies?

The front contour (shape and internal geometry) of a die used in the drawing process plays a crucial role in determining the quality of the final product. Even small variations or errors in the angle, taper, or other geometric profiles can negatively affect the strength, lifespan, and performance of wires, rods, or cables. When a die is geometrically accurate, all products drawn through it are more likely to meet design specifications and perform reliably under real-world conditions.

Importance of Geometry in Dies?

The front contour (“shape” and “internal geometry”) of a die used that is employed in the drawing process are important factors in determining the quality of the resulting product. Even small variations or mistakes in the angle, taper, or other profiles can result in damaging the strength, life-time and other uses for wire, rods, or cable. When a die is geometrically accurate, all products resulting from that die are not only believed to achieve design parameters for those products performing in a field condition.

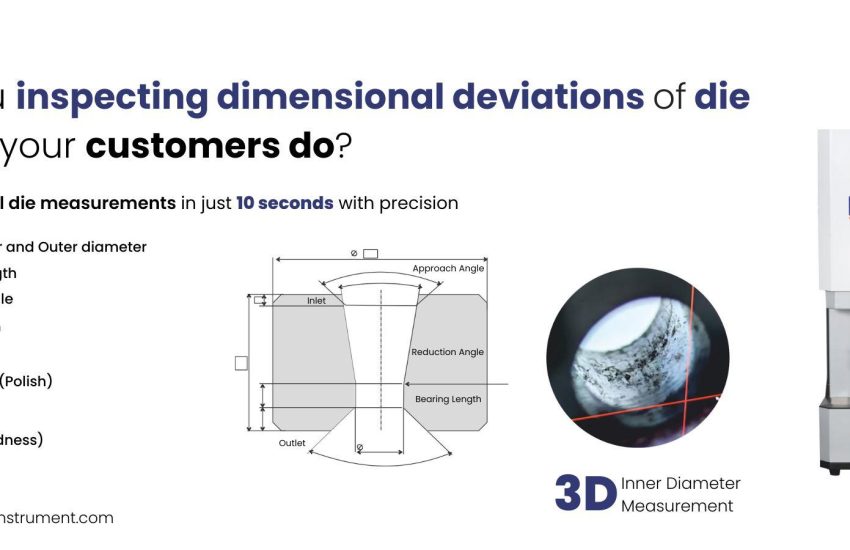

Parameters Checked in Australian Manufacturing companies

In Australia’s manufacturing sector, we use drawing die geometry machines to assess each integral part of a die. These machines inspect parameters like

1. Width – the die ensure that precisely obtain measurements

2. Levelness – inspection for bumps and dents that affect objects

3. Taper – Check that the gradual taper is accurate to achieve enough shaping

4. Polishing – smoothing to minimize friction or abrasion

5. Symmetry – goal is to continuously launch a balanced die that always generates true results.

The capability is to empower manufacturers to maintain quality standards for every production run, minimize waste, and make certain every rod, wire or cable leaving the manufacturer is the most(good) possible quality.

Drawing Die Measurement Machines & Systems

Drawing Die Measurement Machine

A drawing die measurement machine provides Smart sensors and software allow these machines to minimize human error and repeat the same reliable results again

Automated Drawing Die Measurement Systems

There are more such factories in Australia. Such systems employ intelligent software, along with accurate measuring devices, to accelerate inspections and maintain consistency in results. It is part of a broader move in manufacturing smarter, more efficient ways of working.

Role of a Drawing Die Inspector

Functions and Responsibilities: Even with all the equipment available today, nothing can replace the sharp eye and special knowledge passed by a drawing die inspector. While today’s equipment relies on smart software and sophisticated measuring appliances that can accelerate verification efforts and bring further consistency to them, it is the experience of the inspector that primarily achieves the job done. Humans and machines working together is a smarter, more reliable way to run a manufacturing operation

With Microscopes and Other Measuring Equipment

In Australia, inspectors most use microscopes and optical comparators to look for wear, spot minute defects and verify die quality. Their hands-on experience combines with the precision of these devices to ensure manufacturers can rely on each die and everything created with it will be top-quality.

Applications of Drawing Die Measurement in Australia

1. Cable and Wire Manufacturing: For household wiring to power for EV or giant cables, the measurement of drawing die ensures that every cable and wire conforms to rigorous quality requirements and safety. It allows companies to keep close tabs on size so it is consistent and free from defects that may lead to a failure down the line.

2. Mobility Parts: Tapping in to the drawing die measurement can help manufacturers measuring and improving performance and minimize risk of failure

3. Precision Engineering Industries: In sectors especially in aerospace and defense, the need for accuracy is higher than ever. In this aspect, drawing die geometry machines and 3D profile measurement systems are critical to provide global quality standards, regulatory fit & function requirements, and performance goals.

How to Choose the Right Drawing Die Measurement System in Australia

Accuracy and software compatibility: Machine manufacturers should be looking for machines that produce accurate results with 3D profiling capabilities, and that can be easily integrated into your software to minimize the time it takes to report out data.

What suppliers and factors manufacturers need keep in mind

Local suppliers tend to provide more timely service and easier maintenance; an overseas system may give more features. Australians can choose for themselves good performing and reliable Drawing Die Measurement System manufacturers.

Conclusion: Future of Drawing Die Inspection in Australia

Manufacturers in Australia know that precision is not just an end it is the measurement of all things. “With the benefit of drawing die measurement machines and modern inspection systems, companies can work smarter they can cut down on errors in production, operate more efficiently and ensure that every product it ships out the door is of the highest quality. If you are looking to invest in accuracy and consistency, knowing the Drawing Die Measurement Systems Price can help you choose the right solution for your manufacturing needs.

Contact us: +61 426 368 868

Email: export@sipconinstrument.com