Drawing Die Measurement Systems in the USA – Machines, Geometry & Applications

What’s Drawing Die Measurement?

Authenticity plays a crucial role in the modern manufacturing industry in America. To ensure consistent quality, drawing dies, which are tools for sculpting wires rods and tubes, must be carefully analysed. Uneven wires, weak cables, wasted material, and production delays are potential consequences of using a die that is uneven. Advanced drawing die measurement machines are manufactured to detect problems early on and deliver consistent, robust products. This is why they use them so often

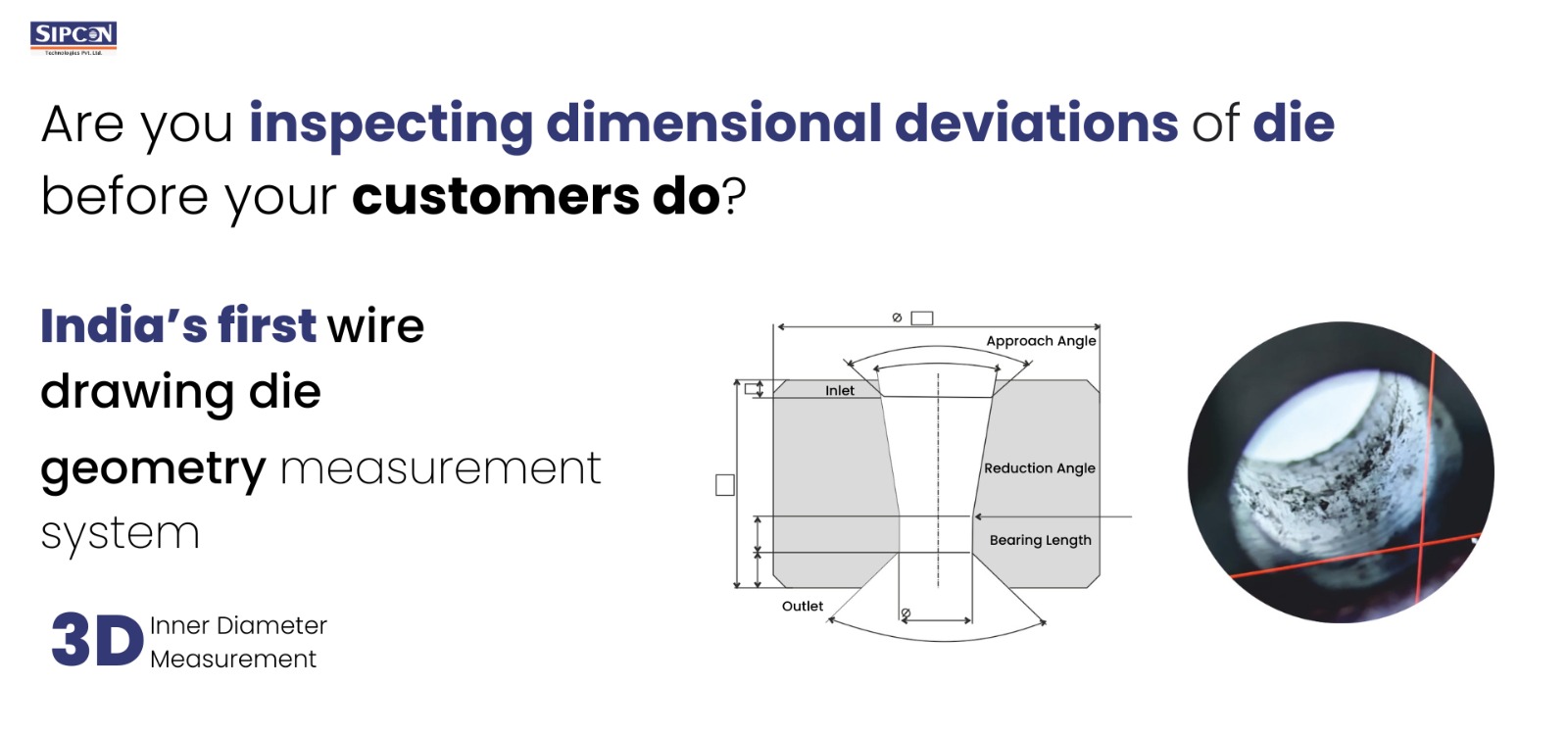

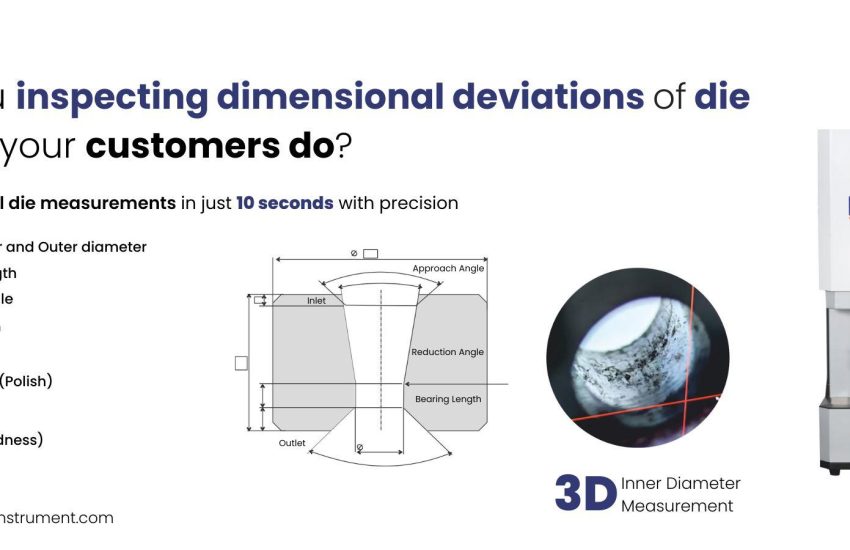

Understanding Drawing Die Geometry Measurement

Wires and rods are made with the shape of the drawing die (the inner part of this geometry), simultaneously more consistent. Geometric Dimensioning, taper, and polish are made possible by using drawing die measurement machines, geometry systems, or 3D profiling tools in U.S. manufacturing, with support from experienced drawing den inspectors. Despite small errors, die geometry is crucial for producing high-quality, reliable, and durable products due to its potential for defects, waste, or delays.

- Precise dimensional inspection plays a crucial role in quality control of U.S. manufacturing. Companies use supported by experienced personnel specialized machines designed for measuring drawing dies with precision and accuracy. Drawing die measurement machines, drawing der geometry machines, drawing die 3D profile measurement systems are most used.

- Machines in the U.S. wire, cable, and metal manufacturing industries demand accuracy, repeatability, smart software, etc.”. Reproducibility is a must-have when dealing with drawing die measurement and geometry machines, which can detect even slight inaccuracies. With the help of profile systems die inspectors, data is monitored, problems are spotted early, ensuring reliable production

Drawing Die Measurement Machines & Systems

U.S. companies use drawing die measurement system and 3D scanning to capture every curve and detail of fabricated parts. Enhanced using automated measurement systems and experienced inspectors, it helps identify defects while minimizing waste and ensure that wires are strong, consistent with quality materials. Additionally, cables must be tested for wear before they can become dangerous.

- Precaution is crucial for aerospace and defense U.S. manufacturers use drawing die measurement systems, geometry machines, and 3D profile systems to ensure that every wire and rod is strong, and free of defects. Using experienced inspectors not only reduces waste but extends the life of dies, allowing to produce safe and challenging application.

- Small errors in manufacturing can lead to major issues. Human error is reduced by automated drawing die measurement systems and 3D profile systems, which check every curve and angle of a die. Skilled drawing die inspectors complement this to ensure the consistent, reliable, and high-quality wires/rods & cables while saving time and money.

- U.S. manufacturing plants are embracing Industry 4.0 to increase output and accuracy in their operations with great precision. Real-time monitoring of dies is achieved by die measurement systems, geometry machines, and 3D profile systems to minimize waste and prevent downtime. Combined with competent drawing die the inspectors process safeguards that wires, rods, and cables are of consistent quality and reliable.

Role of a Drawing Die Inspector

Automated drawing die measurement systems, geometry machines, and 3D profile systems are used by drawn die inspectors in U.S. factories to identify problems early in the manufacture. To ensure consistent, efficient, and high-quality wires, rods & cables are produced, operators / engineers maintain the machines, analyse data.

- U.S. manufacturing relies heavily on precision. The use of microscopes, optical comparators, and drawing die measurement systems allows inspectors to identify minor imperfections, validate shapes, or capture complete die design. Using these tools, which are expertly maintained by drawing die inspectors and reduced waste ensure that wires, rods (plies), and cables are of consistent, high-quality, durable materials.

Applications of Drawing Die Measurement in U.S. industrial sectors

Industries use drawing die measurement systems, wire and cable manufacturing, automotive, aerospace, defence (P&O), and precision engineering (PCI). They give durable, and homogeneous shaping of wires, rods & metal parts. High-quality production, reduced waste output, and compliance with industry standards of manufacturing equipment like geometry machines, 3D profile systems are experienced drawing die inspectors.

How to Choose the Right Drawing Die Measurement System

It is crucial to prioritize features like accuracy, 3D support, integrated software, and accurate data reporting.

- Locally produced and imported drawing die measurement machines are available for purchase by manufacturers in the U.S. It is common for local machines to provide faster support, while imported models have functionality Irrespective of drawing die inspectors die inspectors and seamless integration with geometry and 3D profile ensure that products are reliable, and of high quality.

- U.S. manufacturing requires regular servicing and calibration of drawing die measurement machines to ensure their accuracy and reliability. Rapid resolution to issues is achieved through technical support, resulting in reduced downtime with the skill drawing die inspectors and proper machine maintenance, manufacturers can produce wired rods, cables, and other materials with super quality standards.

The Future of Drawing Die Inspection

Smarter and more efficient inspection is being used in U.S. manufacturing in the future. The use of AI, automation, and smart data tools, inspectors can quickly catch defects, cut down on waste, and keep wire, rod, and cable quality consistent. In fields like aerospace, defence, and automotive, every tiny detail counts, and getting things precise is essential. Using drawing die geometry machines and 3D profile systems, along with trained drawing die inspectors die inspectors. This focus on quality allows them to produce reliable parts efficiently and stay competitive in today’s fast-paced market.

Conclusion and CTA

If these perspectives on drawing die measurement resonate with your work, let us connect and continue the conversation. At SIPCON, we would be glad to hear about the challenges you face and explore how these approaches could fit into your operations You can reach our team directly at sales

Need Help? Call Our Experts for Drawing Die Measurement Systems Today!

Write to us at us@sipconinstrument.com or visit www.sipconinstrument.com/us/ to start the conversation.