How Can One Machine Measure Everything? The Magic of Multi-Sensor 3D Systems

SIPCON Technologies, we hear this question on a nearly daily basis: How do we get measurement on this complicated part quickly and accurately? You are making intricate automotive parts in Pune, precision aerospace parts in Bangalore, or sophisticated medical devices in Hyderabad. the journey to perfection is universal. A solution to the modern manufacturing measurement dilemma often uses an amazing technology like a Multi-Sensor Three-Dimensional Measuring System.

Also read: What is Multi Sensor Three Dimensional Measuring System

So, what is it? And how does it work its magic? Let us explain how this engineering masterpiece works in a way that resonates with our everyday quest of excellence through ‘Make in India’.

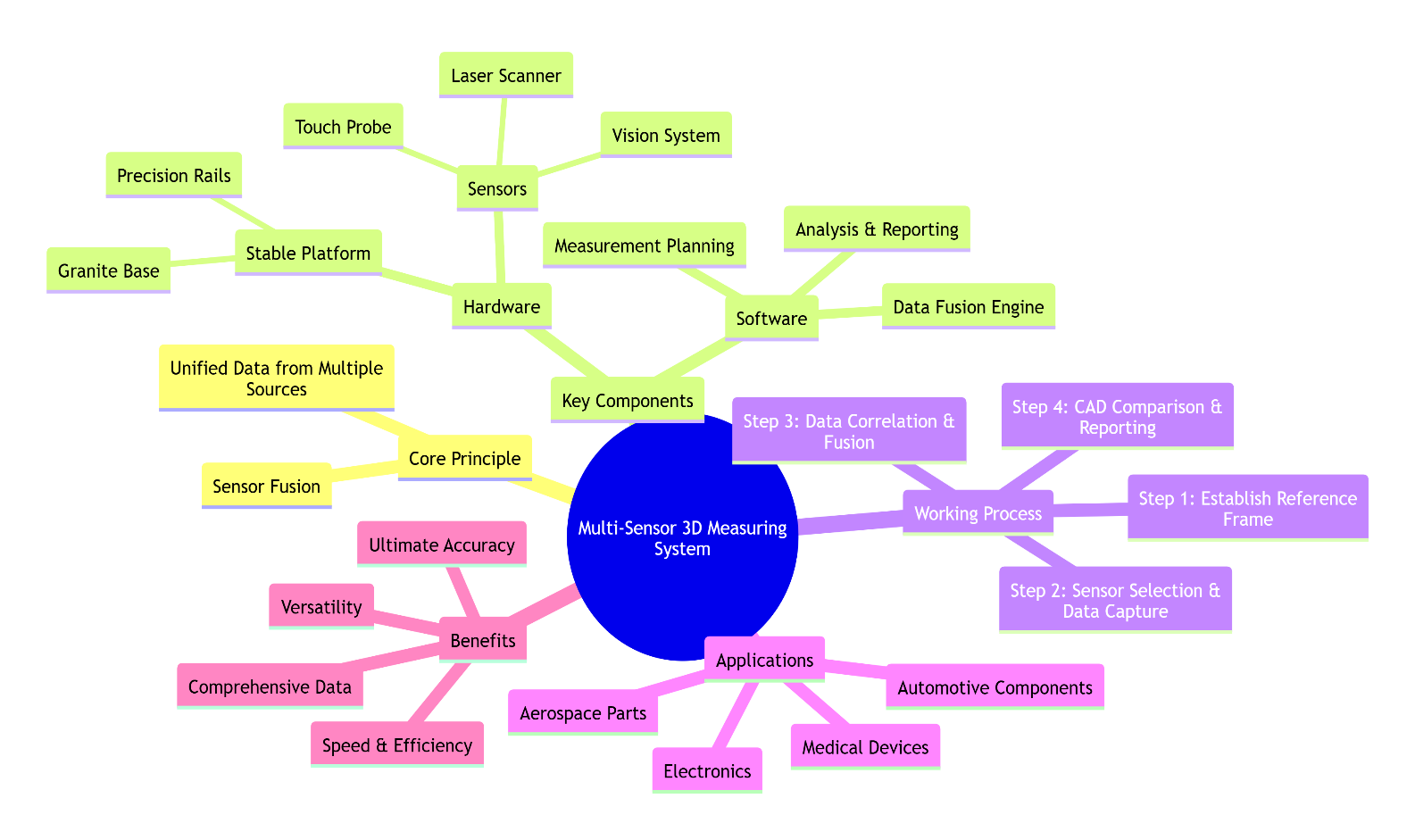

The Fundamental Principle: One System, Many Eyes, One Truth

A core concept of a Multi-Sensor Three-Dimensional Measuring System can be boiled down to the simple but powerful, concept of sensor fusion. Take, for example, a complex sculpture. You could describe its smooth contours by feeling it with your fingers (like a touch probe), tell me about its distinguishable engravings visually at it with your eyes (like a vision system), and You could choose up a laser pointer to pinpoint how tall it is (like a laser scanner).

That is what a multi-sensor CMM does; it combines multiple types of measuring sensors on a single precision platform, so it can get multiple types the same part without having to re-fixture. It can do this, because it is more than just a mechanism; it is a multi-modal sensor inspection team that operates unified system.

Breaking down the “How”: The process

Let us now discuss the working of this system, like how we would talk about a quality inspection protocol.

Step 1: The Base – The Stable Platform and Coordinate System

Every measurement begins from a known reference. The system is built on a rigid structurally stable granite foundation, avoiding thermal expansion and vibration. It defines a The creation of reference universal spatial reference.” or origin, ensures that all sensors capture data in the same spatial reference

Step 2: The Guiding Hand – The Probing System and Motion Control

The sensor head along each of the three linear axes with pinpoint accuracy Using the tactile or touch-trigger probe, the traditional workhorse of CMMs, the system performs contact measurement. Upon contact with the CMM the probe touches the part surface, a signal is sent to the system, which capturing the accurate X, Y, Z coordinates of the test probe. The system can define the form, size, and position of features like holes, slots, and planes.

Step 3: The Keen Eye – The Optical Vision System

This is where things get interesting for parts with complex features. For geometry that may be very small, very soft, and/or has a complex 2D shape, The system automatically adjusts to its high-resolution camera system. The part is illuminated from above or behind and provides a sharp, vivid image with high contrast. Through sophisticated software, the system will detect the part. For example, it can find dozens of tiny hole diameters in an instant, or intricate contour of a stamped sheet of metal part without through contact probing.

Step 4: The Laser Focus – The Non-Contact 3D Scanner

The laser scanner is used for free-form surfaces, contours, and reverse engineering. It emits a line or pattern of projects a laser onto the surface of the part. One or more cameras see the deformation of that line. The software determines each of the locations along that line by the principle of triangulation, producing a high-resolution” of millions of 3D coordinates that spatially define the surface topography of the object.

To illustrate how these multiple sensors contribute to a complete digital image

The “Brain”: Where the Magic of Fusion Happens

The real brilliance of a multi-Sensor 3D Measuring System is not in the equipment it is in the software that is the brains of the operation. This is a place where the magic of sensor fusion happens.

- Single Program: The operator creates a single measurement plan.

- Sensor Selection: The software chooses the appropriate sensor for each feature automatically. Use the touch probe for datums and critical bore depths, use vision for tiny holes, and use the laser for scanning complex curvature.

- Data Fusion: Because every sensor is working same, the touch probe, the camera, and the laser data are combined into one digital model.

- Analysis and Reports: The software identifies discrepancies from the complete data set and the original CAD model, pinpointing variations and providing simple reports containing that information. This gives the user one source of truth with respect to the geometry of the whole part.

Why is this Important for “Make in India”?

For manufacturers in India, it is not just advanced technology; it’s real competitive advantage.

- Speed: Inspection time for complex parts can be reduced by as much as 90%.

- Versatility: One system can handle a variety of product mix from a simple bracket to a complex turbine blade.

- Assured Accuracy: It mitigates human errors introduced by manual handling and fixturing across multiple machines.

- Complete Data: It provides a full that reveals intricate details allows you to to improve process and minimize waste.

Conclusion & CTA

The Future of Precision is multi-dimensional

With quality the new currency relying on a reduced-dimension model. A Multi-Sensor Three-Dimensional Measuring System signifies a shift moving from Seamless verification

ring that what you build is ultimately what you have designed. Are you ready to take your quality control to the next level? Why except for the archaic limitations of single-sensor measurement when you could have one solution? SIPCON Technologies is here to assist you. Contact our measurement experts today for a consultation that is personalized for you! Find out how a multi-sensor CMM will redefine your quality control, save you money, and bring speed to your breakthrough. We would love to connect at info@sipconinstrument.com, or check out our website https://www.sipconinstrument.com

Phone: +91 82229 29966