Profile Projector Machines in Russia – Optical & Digital Measuring Solutions

Introduction

Across Russia, industries such as automotive, aerospace, electronics and tooling rely on dimensional inspection to maintain manufacturing accuracy. Tight tolerances, higher production volumes, and global quality expectations have developed advanced optical measuring systems as a necessity rather than a choice.

For Russian manufacturers looking for dependable, non-contact measurement with consistent accuracy, profile projector machines have emerged as a proven solution. These systems are changing to satisfy contemporary inspection requirements while preserving ease of use and dependability on the shop floor with the gradual shift to digital and camera-assisted technologies.

What is a Profile Projector Machine?

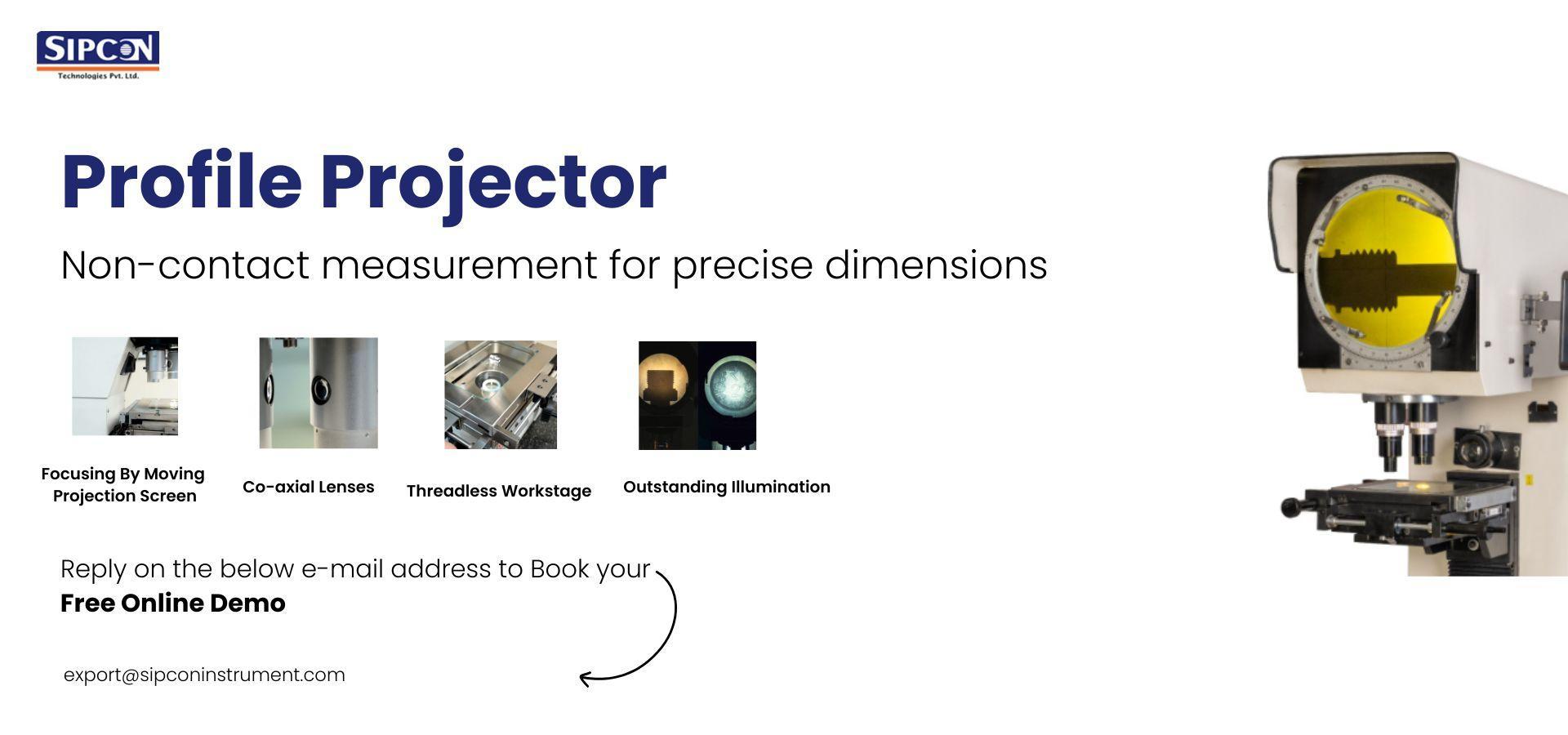

A profile projector machine, also known as an optical comparator, is a precision measuring instrument used to inspect the geometry of components by projecting a magnified image of the part onto a screen or monitor. Measurements are taken by comparing the projected profile against reference lines, charts, or digital overlays.

The operation principle is simple, but it’s highly effective. The light that passes through or reflects off the component forms a unique silhouette, which is magnified with optical lenses. By using this image, inspectors can evaluate dimensions, angles, contours and surface features without physically touching the part.

In manufacturing facilities in Russia, profile projectors take a significant role in the quality control process to guarantee that the pieces they produce fall within very strict ranges before sending them out. They are contactless, which is especially suitable for fragile, high-precision, machined, or fine-finished components.

Leading Profile Projector Manufacturers in Russia

Profile projector manufacturers in Russia support a wide range of industries by supplying dependable measuring solutions designed for long-term industrial use. What makes this manufacturer stand out is its emphasis on both equipment quality and service reliability, calibration support, and operator training.

Local suppliers offer several advantages, including faster service response, easier communication, and customization based on application needs. Meanwhile, foreign companies working in Russia have been providing cutting-edge optical and camera technologies that can compete worldwide.

Profile Measuring Machines, Accuracy in Every Dimension

While profile projectors are widely used for visual inspection and 2D measurements, profile measuring machines extend these capabilities through digital sensing and software-based analysis.

These systems combine optical projection with camera technology and measurement software to evaluate geometries, contours, and features with higher repeatability. Measurements are captured digitally, allowing for reliable data storage, reporting, and traceability.

Across Russian aviation, defense, medical and precision tool facilities, profile measuring machines are relied on because tolerances leave little room for error. When measurements stay consistent and inspections move faster, quality control becomes easier to manage over long production runs.

Optical and Camera-Based Profile Projectors, Practical Comparison

Modern profile inspection systems in Russia now include both traditional optical projectors and camera-based profile projectors. Each serves specific inspection needs, depending on accuracy requirements, part complexity, and reporting expectations.

Traditional profile projectors rely purely on optical magnification. The component image is projected onto a screen using lenses, and measurement points are manually probed using a crosshair. These systems are 2D only but work well for everyday measurement needs. They are a cost-effective, easy-to-use solution for workshops and production environments where accuracy is critical.

Camera-based profile projectors enhance this process by using a camera in combination with optical lenses. The image is displayed on a monitor and the probed points are automatically processed by software. Features such as lines, arcs and circles are calculated digitally, improving consistency and reducing operator dependency. These systems offer higher resolution, improved field of view, optional image capture, and digital reporting in formats such as Excel or PDF.

Both systems support CAD (DXF/IGS) export and GD&T evaluation in 2D. While neither is intended for full 3D measurement, camera-based projectors can be upgraded to 2.5D for limited height measurement, offering greater flexibility for advanced inspection tasks.

Choosing the Right Profile Projector in Russia

Selecting the right profile projector depends on application requirements and production goals. Key considerations include measurement range, magnification capability, image resolution, lighting system, and software compatibility.

Equally important is knowing that service engineers and calibration support are available locally in Russia. Dependable after-sales support guarantees long-term accuracy and reduces downtime. Tooling, sheet metal fabrication, electronics, medical components and automotive manufacturing industries all reap the benefits of flexible systems that can accommodate differences in part sizes. Industrial Image Processing Systems are designed for practical application.

A well-chosen profile projector improves inspection efficiency, enhances quality consistency, and supports compliance with international standards.

Future of Profile Measuring Technology in Russia

The future of profile measuring technology in Russia is closely tied to automation and digital integration. Manufacturers are increasingly embracing solutions to facilitate CAD connections, digital data management and Industry 4.0 efforts.

Hybrid optical–digital systems are also emerging, which provide the streamlined visual perspective of pure optical projection with software-driven efficiency. Progress in camera resolution, data processing and AI-enabled inspection should accelerate speed, accuracy and traceability across manufacturing verticals.

As Russian industries continue modernizing their quality control processes, profile projector machines will remain a cornerstone of precision inspection.

Reliable Profile Projector Solutions for Russian Industries

Measurement is a critical function for today’s suppliers and manufacturers, as companies require the precision measurement process to be more accessible. Profile projector machines (either optical or camera type) are indispensable to control the dimensions of parts in all industries in Russia.

Choosing the right profile projector manufacturer is not just a purchasing decision; it is an investment in long-term measurement reliability and production confidence. SIPCON Technologies offers a comprehensive range of high-precision profile projector machines and profile measuring systems designed to meet the evolving needs of Russian manufacturing.

To learn how SIPCON’s optical and camera-based solutions can enhance your inspection accuracy, connect with our experts today.

📧 export@sipconinstrument.com

🌐 https://www.sipconinstrument.com/contact.php

📞 +91 92156 99661