Profile Projectors in Russia: Precision Horizontal, 2D, 3D & Optical Technologies

The Russian aerospace, automotive, defence, and cable production industries require precision and accuracy. All parts, including the smallest electronic element and huge cable segments, have to meet the norms of GOST and ISO. In order to fulfil such requirements, manufacturers are dependent on profile projectors, which are non-contact and offer highly reliable inspection of part dimensions.

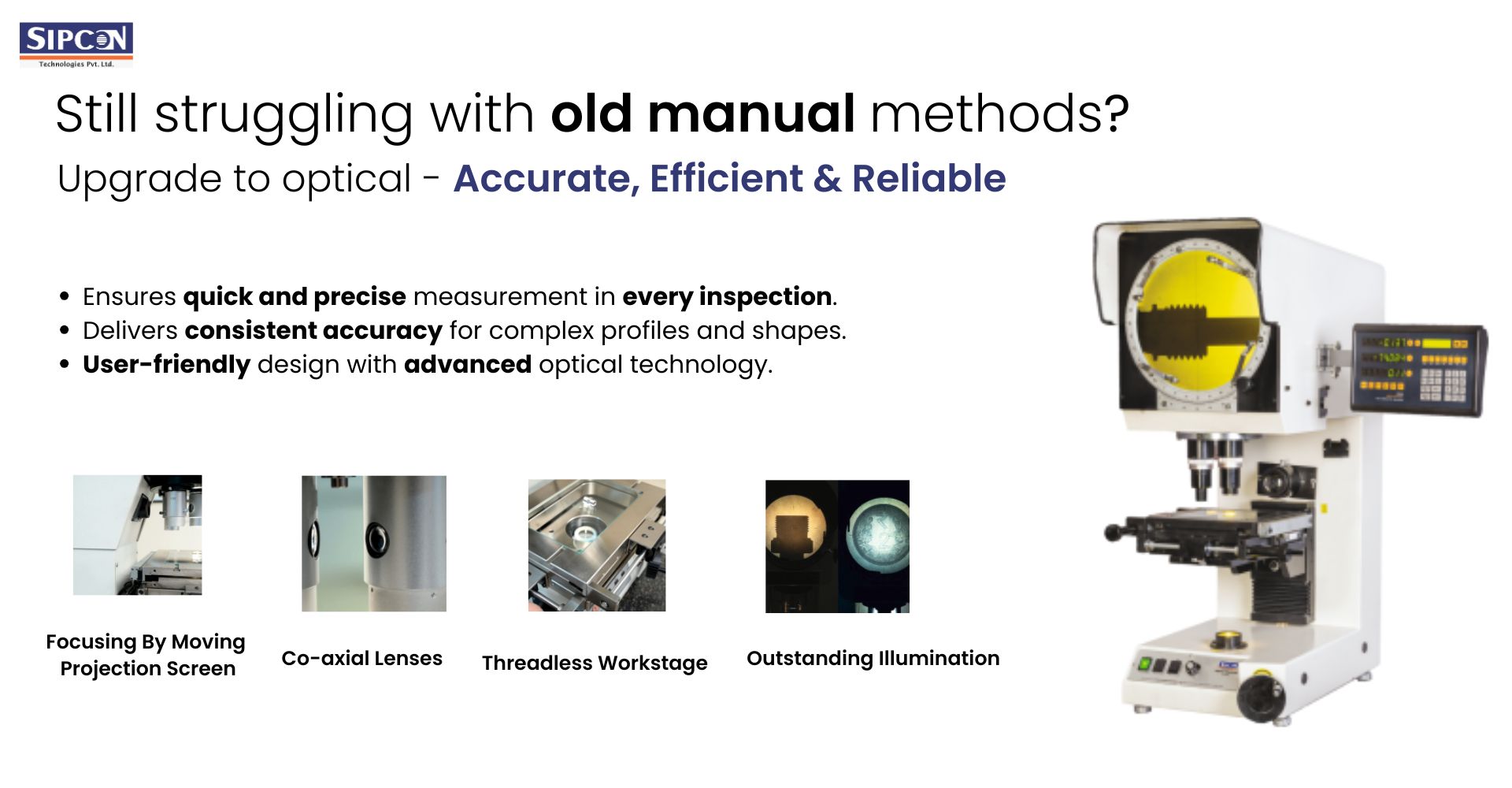

A profile projector is used to enlarge the shape of a component on a screen so the operators can compare the geometry of the component to standard drawings or CAD models. These machines can be bought in various forms, including horizontal, 2D, 3D, and optical projectors, and therefore cannot be ignored in quality control.

Sipcon is a well-established brand in Russia known to provide superior projector-based systems of measurement. Be it a 2D Profile Projector to perform simple checks, a 3D Profile Projector to perform complicated inspections or a Projector to perform cable performance, Sipcon will make sure that manufacturers are able to produce with global precision and at the same time with efficiency.

Introduction to Profile Projectors

What is a Profile Projector?

An optical comparator or profile projector is an accurate tool that can be used to measure an object by enlarging its shape on a screen. It allows operators to verify such parameters as the length, angles, radii, and diameters.

Importance in Russian manufacturing industries.

The profile projectors are required in Russian manufacturing industries to:

- Machined and moulded parts- Dimensional accuracy.

- A decrease in the rejection rates and rework.

- Adhering to local (GOST) and global quality standards.

The Horizontals of Profile Projectors in Russia.

How horizontal profile projectors work.

Horizontal profile projectors view a magnified image in a horizontal direction; hence, they are used with long or cylindrical-shaped objects.

Best for longer components and cable sections

Such systems are perfect when it comes to inspecting shafts, cables, tubes, and extruded components, which are difficult to inspect vertically.

Common Russian industry applications.

Sipcon horizontal projectors are also popular in Russia in cable manufacturing, automotive machining and aerospace workshops. Grooves, insulation thickness, and diameters are accurately measured, which facilitates faultless production.

2D Profile Projectors – Traditional and Reliable

Role of 2D profile projectors in Russian industries.

The 2D Profile Projector is a household item of the Russian workstations, providing effective inspection for the routine manufacturing procedures.

Key measurements: length, diameter, angles

It helps in the measurement of simple dimensions like diameter, angles, radii, and lengths.

Affordable inspection for routine checks.

The Sipcon 2D Profile Projectors have also received appreciation due to their low cost, which makes them ideal for the routine inspection of machining, moulding, and assembly lines where quality inspection at a low cost is reimbursable.

3D Profile Projectors – Advanced Solutions

Introduction to 3D Profile Projectors

3D profile projectors are becoming more popular in the healthcare industry due to their ability to offer a three-dimensional (3D) image of the patient during the examination process.<|human|>Introduction to 3D Profile Projectors Introduction to 3D Profile Projectors are increasingly being used in the healthcare sector owing to their capability to provide a three-dimensional (3D) image of the patient as part of the exam procedure.

The present technology development in the measurement business is the 3D Profile Projector that offers chic and automated inspection systems.

Benefits: CAD comparison, automation, and detailed geometry.

Sipcon’s 3D systems allow:

CAD model direct comparison.

Inspection procedures that are automated.

Complex geometry and surface geometry capture.

Aerospace, Defence, and Electronics adoption in Russia.

The Russian aerospace, defence, and electronics manufacturers count on the 3D projectors of Sipcon to provide the turbine blades, defence, and micro-electronics. Their potential to decrease the reliance of the operators and provide the inspections of high velocity is transforming the quality control in high-tech industries.

Optical Projectors vs Digital Projectors

The difference between optical projectors and modern digital projectors.

Optical Projectors: Light and Lenses are used to project magnified images.

Digital Projectors: This integrates high-resolution cameras and software used in CAD, automation, and reporting.

Why do many Russian companies still use optical systems?

The reason behind most of the Russian manufacturers choosing optical projectors is their simplicity, durability, and cost-effectiveness.

Transition to digital for smarter factories.

Nevertheless, as Industry 4.0 in Russia develops, an increasing number of industries are going digital. Sipcon facilitates this change, and it provides optical and digital solutions.

Profile Projectors for Cable Manufacturing in Russia

Why cables need projector-based inspection

To guarantee performance and safety, cables need to be insulated precisely in terms of insulation thickness, concentricity and defect detection.

Measuring insulation thickness, concentricity, and defects.

Cable profile projectors have been made by Sipcon that are designed to scan the full depth of a cable, including insulation to sheathing, to check whether they are properly measured.

Meeting Russian quality standards (GOST, ISO).

These checks are used to ensure that cable manufacturers are in line with the Russian GOST standards and the ISO certification to ensure that the cables are up to the standard required by the country and internationally in terms of reliability.

Choosing the Right Profile Projector in Russia

Horizontal vs vertical projectors.

Horizontal projectors: Horizontal projectors are used with long and cylindrical parts such as cables.

Vertical projectors: Ideally suited to flat parts and small parts.

2D vs 3D Systems

2D Profile Projectors: These are the most suitable when it comes to basic and regular checks.

3D Profile Projectors: This is necessary when there is complex geometry and automation.

Significance of Local Support and Training.

Sipcon insists on the local service, calibration, and training of the operators and provides Russia with the highest ROI and durability.

The manufacturing future of Russia is moving towards the new system of digital-first and automated inspection, as opposed to traditional inspection. Although 2D Profile Projectors and Optical Projectors will remain a reliable instrument, the 3D Profile Projectors and digital systems will lead the next round of revolution in the industrial world.Increase quality control with the Sipcon profile projector lineup in Russia. Our solutions are based on the requirements of the 2D, 3D, horizontal, and optical systems and are accurate, compliant with the GOST and ISO systems, and reliable over the long term.

Discover the Right Profile Projector for You – Contact Our Specialists Today!

Get in touch with Sipcon and modernize your production with measuring equipment of global standards. Send us a letter to export at export@sipconinstrument.com or in https://www.sipconinstrument.com/ to get started.”