Profile Projectors in United States – Optical, 2D & 3D Instruments for Precise Measurement

Profile Projectors in the USA | Optical, 2D & 3D Profile Measuring Machines

Explore optical, 2D, and 3D profile projectors in the USA. Learn about vertical profile projectors, profile projectors for cables, and advanced profile measuring machines for precision industries.

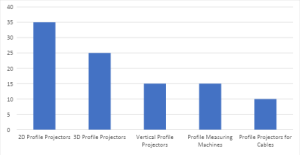

| Category | Usage % |

| 2D Profile Projectors | 35 |

| 3D Profile Projectors | 25 |

| Vertical Profile Projectors | 15 |

| Profile Measuring Machines | 15 |

| Profile Projectors for Cables | 10 |

In American manufacturing, precision is not only a competitive advantage it’s an imperative. In industries aerospace, defence, automotive, electronics and cable, even the smallest error can be quite high. Profile projectors are still important to keep in mind is you want accuracy and quality.

This guide discusses profile projectors in use by U.S. industries, the different kinds available and how they’re changing with technology.

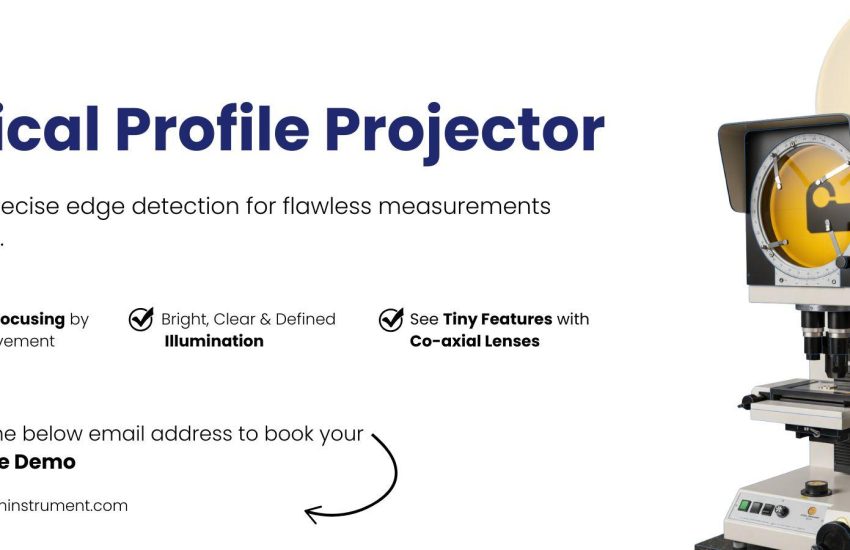

What is an Optical Projector in Production?

An optical projector is named Profile projector is a device that enlarges the image of an opaque or transparent specimen or of an emitting object and projects the enlarged image on a screen. This magnified view allows operators to compare shapes, sizes and angles against design specifications.

How it works?

A beam cast a shadow of part across lenses onto a screen. Operators can compare the blueprint with templates or CAD overlays.

Why they’re still used in some U.S. industries?

Even with the growing popularity of high-tech digital inspection systems optical projectors are still one of the most commonly employed methods due to the fact:

- Easy to Use – Almost no training necessary.

- Dependable – tested for the industry for decades.

- Affordable – pinpoint accuracy without the expensive equipment costs.

- Vertical Profile Projectors – High Precision for Flat and Cable Parts

Vertical profile projectors are configured such that the path is vertical and correspondingly, it can be used for measuring thin parts or flat parts.

Benefits

good for gaskets, washers and electronic circuits.

Beneficial to check wire Layer views, measure the conductor loss or buried wires; and track windings of motor and transformer or under carpets.

U.S. industry applications

The vertical projectors are commonly used in electronics, cable production and automotive plants here in the United States for day-to-day quality control.

- 2 Dimensional Profile Projectors – Dependable Checking for Sizes.

A 2-dimensional profile projector for length, height, diameters and angles is used.

Advantages

Inexpensive relative to state-of-the-art 3D devices.

Accurate enough for most industrial purposes.

Popular in the US factories for regular tests.

Because of their ease-of-use and performance, they are the tool of choice for QA teams requiring fast verification regarding measurements

- 3D Profile Projector Machines – cutting-edge measurement of complex parts…

A 3D profile projector goes beyond and captures depth in addition to length and width.

How they work

The art of optical scanning and digital processing allows complete 3D geometry analysis, which is often compared back to CAD directly.

Benefits

Complete shape verification.

Automated data reporting for inspections.

Perfect for intricate parts with curves and angles.

Key U.S. industries

3D projectors are used for precision and compliance at the highest levels in aerospace, defence and medical device manufacturing.

Profile Projector for Cables to the USA

Cables are necessary to everything from automobiles to telecom networks. Making sure they do are an essential requirement

Why cables need projector-based inspection?

- Detect insulation layer depth

- Examine for concentricity (the levelness of layers).

- Catch glitches before production even continues.

- In the U.S., in sectors like automotive & telecommunications, cable and profile measuring machines are used for many applications to ensure that safety & performance requirements are met.

- Profile Measuring Devices – More than Just Projecting

- Where traditional projectors relay on optics, a profile measuring machine plays with sensors and digital analysis for more automation.

Manual vs. automated

- Manual systems: requiring operator intervention, cheaper investments and suitable for small production batch.

- Automation: speedy, Consistently perfect for the United States smart factories of the future they head for Industry 4.0.

These self-automating machines are spreading like crazy through U.S. industrial hubs.

Selecting the proper profile Projector in USA

In choosing the right system, American manufacturers frequently take into account:

- Optical vs. Digital – classical shadowgraph or image-based evaluation.

- 2D vs 3D – When To Use One Over The Other Based on Part Complexity.

- LOCAL SERVICE & CALIBRATION – Suppliers available in the U.S. for local service, calibration and faster response time, meeting local requirements.

Conclusion & CTA

What now for Profile Measurement?

Profile projectors – optical, vertical, horizontal, 2D or 3D – are still an important cornerstone of U.S. industry. They bring precision, consistency and reliability to every step of production. With automatic profile measuring machines under continuous installation, the future is a mix of old fashion reliability together with state-of-the-art smart-factory integration.

For U.S. manufacturers, the decision of what projector to select is not merely one of inspection, but one of quality, safety and reputation.

Get in Touch : us@sipconinstrument.com or visit http://www.sipconinstrument.com/us to start the conversation Contact Number: +1 (262) 391-4785