Revolutionizing Quality Checks in Seconds with Rubber Seal Genie

Very simple rubber seals are key elements in so many different industrial applications. This is evidenced, for example in automotive door seals to appliance gaskets, where they are contributing to safety or efficiency or reliability of the product. But the inspection of such seals has historically been a difficult job, because rubber is a soft and flexible material. Even small misalignments out of geometry can lose the sealing function, resulting in leaks and damage or customer annoyance.

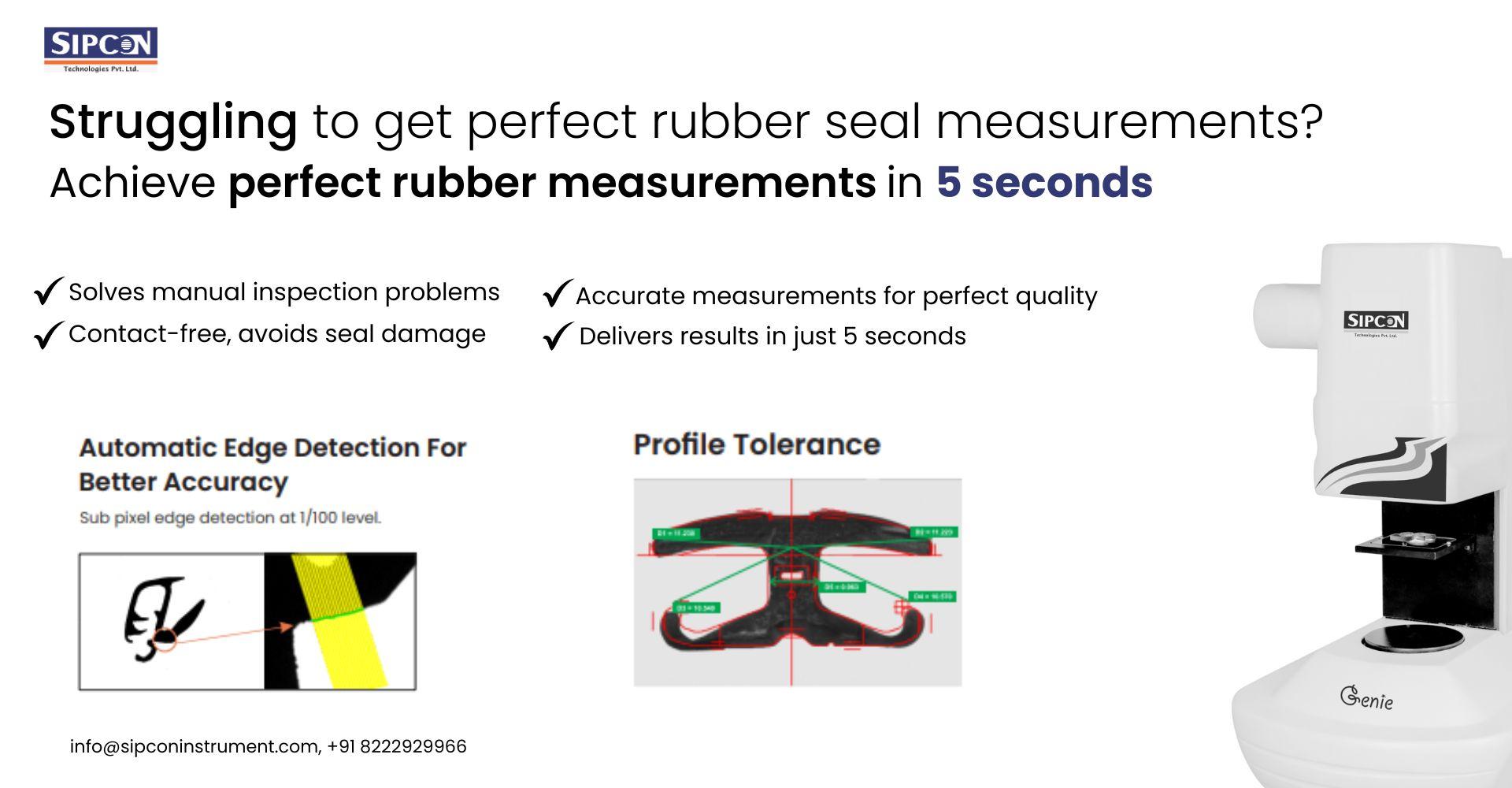

Introducing SIPCON’s innovative system like Rubber Seal Genie, a state-of-the-art inspection system using digital optics, controlled lighting and high-speed vision algorithms to achieve non-contact inspection in just seconds.

Why These Seals Are Hard to Inspect

It is difficult to visually check the rubber seal. There are several factors that make this an incredibly challenging measurement:

- Material Compliant: Rubber material loses a realistic deformation even with touch, this is the opposite for metals. 3. Traditional inspection instruments or calipers can exert a force that compresses the seal, or deforms the seal by rotation, leading to measurement deviations

- Small Geometric Differences Matter: Minute pitch, lip angle or cross section changes may not be visible to the naked eye that can have dramatic effects on performance.

- Soft Surface Behaviour: Rubber will wobble and twist causing the optical measurement more complicated.

- Manual Processes Are Too Inefficient: Many inspections undertaken are manual, slow and highly operator-driven, causing results to suffer from the variance in performance.

- Traceability: Conventional manual methods rarely provide compliance-ready paperwork making it hard to comply with ISO/TS or other quality requirements.

- Industry Ramification: A 2023 study by the Rubber Manufacturers Association (RMA) found that 29% of all rubber seal rejects can be attributed to missed dimensional deviation, rat her than material defect.

How Rubber Seal Genie Solves These Problems

Rubber Seal Genie combats issues pertaining with the old seal inspection process. The system uses a leading-edge digital vision technology to measure rubber seals with precision and speed without physical contact issues or operator intervention.

Step-by-Step Workflow

-

- Apply the Seal: No centring or clamping. Just place the seal over the inspection desk.

- Document the Profile: Use high resolution digital optics and lighting control to produce a distortion-free profile of the seal.

- DXF Auto-Alignment: DXF is automatically aligned with the captured image for accurate comparison.

- Deviation Check: In 5 seconds all forms, lips and angles not fulfilling expectations are highlighted for the operator.

- Automated Reporting: PDF and Excel reports are automatically created and saved for traceability, taking the headache out for quality inspections

- Takeaway: Rubber Seal Genie cuts down inspection time by more than 90 percent and improves accuracy, repeatability and compliance.

Traditional vs Rubber Seal Genie

| Feature | Traditional Method | Rubber Seal Genie |

| Inspection Time | 5-7 minutes per part | <5 second apart |

| Operator Dependency | High | Low |

| DXF match up | Manual | is Fully automatic |

| Touch Accuracy | ±100 µm (+-)) | ±5 µm (non-contact) |

| Reporting Manual | Automated | audit-ready reports |

Industries and Applications

- Rubber Seal Genie is suitable when accuracy, speed, and traceability are important:

- HVAC: Profiles for vibration damping, duct seals and insulation parts

- Third party Testing Labs: High precision is a mandate even for export quality inspections

- Compliance-Focused QA Labs: ISO /TS audits and regulatory validation compliance, and traceable quality documentation

Quantifiable Benefits for Manufacturers

Here is what some Rubber Seal Clients using Rubber Seal Genie have reported saying already:

- Inspection Speed: Up to 90% faster compared to traditional inspection methods techniques

- Accuracy: ±5 µm, even on soft and flexible materials

- Traceability: 100% audit-able reports that are aligned with ISO/TS requirements

- Cost Savings: 70–80% savings on re-inspection and reject part.

- Financial Savings: ₹6–10 lakh/year on Labor and rework costs saved.

Client Testimonial

We perform hand-based inspection taking 5 minutes. Inspecting for seconds using Rubber Seal Genie. The findings are replicable, robust in perfect alignment

Work was completed Core Value Technologies — QA Manager, Leading Seal Manufacturer, Pune

Why Rubber Seal Genie Matters

A minor change in a rubber even a small deviation in a seal can result in serious implications, but it can have widespread effects: leaks, premature wear, customer protests and noncompliance with regulations. With Rubber Seal Genie, these risks are taken away and accurate fully traceable inspections empower QA teams to stop the defects before they start.

- Immediate Inspections: Never get caught with bottlenecking production

- More Accurate – eliminates errors and combined with material hang-ups from benches and plaques.

- Complete traceability: Meets ISO/TS & more quality standards

- Save money: Less labour, less rework and scrapping

- Customer Assurance: Achieve reliable results every time specifications when shipping supportable product

Conclusion and CTA

This accelerates and transforms the rubber seal inspection from slow and mistake-prone to a highspeed, accurate, and traceable inspection operation. Fast complex seal measurement in 5 sec allows manufactures to produce and ensure quality, save costs and deposit with confidence of not being penalized for quality inspections.

👉 See the future of rubber seal inspection – where speed, accuracy and traceability meet: Rubber Seal Genie

📞 Contact us now at info@sipconinstrument.com to schedule a demo and see how 5-second inspections can transform your QA process.

Visit – https://www.sipconinstrument.com/

Contact Number – 91 8222929966