Top Video Measuring Machines (VMMs) in Saudi Arabia for Accurate Quality Control

Precision and dependability are critical in the fast-enveloping industrial manufacturing area. The manufacturing sector in Saudi Arabia is thriving due, in large part, to commitments made under the Vision 2030 program and is seeing a higher demand for quality control and advanced solutions. Sipcon’s Video Measuring Machines (VMMs), which are revolutionizing how industries ensure product integrity. As a leading video measuring instrument manufacturer, Sipcon Instrument Industries from India has extended its footprint to Saudi Arabia, providing state-of-the-art vision measurement systems that enhance efficiency and reduce errors. This blog delves into the intricacies of VMM technology, its applications, and its impact on Saudi Arabian industries, incorporating key aspects like the VMM machine full form, video measuring system least count, and more.

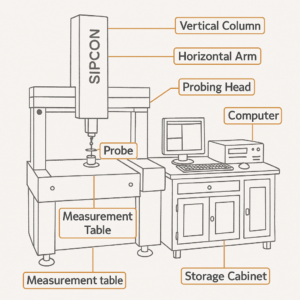

What is a Video Measuring System (VMM)?

A video measurement machine is an advanced metrology instrument that utilizes optics and precision mechanical devices to acquire dimensions of components. These machines are typically utilized where accuracy down to a micrometer is essential.

The VMM machine full form is video measuring instrument, its main task is to provide fast, accurate, non-contact measurements of complex parts.

Key Features:

- High-resolution imaging for accurate measurement

- Non-contact operation to prevent damage to sensitive materials

- Automated measurement capabilities for faster inspection

- Suitable for various materials, rubber, plastic, and metal.

VMM Machine Uses

Video measuring machines are highly versatile, making them indispensable for quality control in a wide range of industries.. Here are some common VMM machine uses:

- Measuring complex geometries in automotive parts

- Inspecting rubber gaskets, seals, and other molded components

- Checking dimensions of plastic components used in electronics

- Ensuring precision in metal parts and machined components

- Reducing manual measurement errors and saving inspection time

Video Measuring Machine for Rubber Parts

Rubber parts often have complex shapes and flexible surfaces that make them difficult to measure in a traditional method. A Video Measuring Machine designed for rubber parts allows a manufacturer to measure tolerances, dimensions, and even thickness without touching the actual parts. This prevents applied forces that might deform the rubber components and provides a greatly increased reliability due to no-contact measuring.

Video Measuring Machine for Plastic Parts

Plastic components in industries like electronics, packaging, and automotive require tight tolerances. A Video Measuring Machine for plastic parts uses optical measurement to ensure every piece meets the required specifications, even for delicate or thin materials.

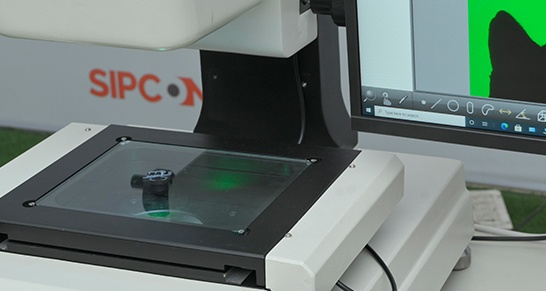

Video Measuring Machine Working Principle

Understanding the video measuring machine working principle helps in appreciating its precision and efficiency.

- Imaging System – A high-resolution camera captures the part’s image.

- Lighting – Using accurate edge detection with LED or fiber-optic lights will enhance contrast.

- Motion Control – The system moves the stage or camera in the X, Y, and Z axes.

- Software Processing – The software provides advanced processing capabilities to analyze the image, determine dimensional measurements, and generate reports.

The combination of optics, mechanics, and software creates a metrology solution with video measurement systems that are precise, fast, and reliable.

Why Choose Sipcon VMMs in Saudi Arabia

Sipcon offers advanced vision measurement systems that meet the demands of modern industries. Here’s why manufacturers prefer Sipcon:

| Feature | Benefit |

| High Accuracy | Measures down to microns, suitable for sensitive applications |

| Fast Measurement | Reduces inspection time, increasing production efficiency |

| Versatility | Can measure rubber, plastic, metal, and hybrid materials |

| User-Friendly Software | Easy to operate, reduces the need for extensive training |

| Robust Build | Long-lasting machines suitable for industrial environments |

| Support & Maintenance | Local support in Saudi Arabia ensures minimal downtime |

Sipcon’s video measurement machine solutions help manufacturers maintain strict quality standards while improving productivity.

Sipcon VMM Models

To illustrate the versatility of Sipcon’s offerings, here’s a table comparing key models:

| Model | Measuring Range (mm) | Least Count (microns) | Software Features | Ideal Applications |

| Manual Video Measuring System | 100x100x100 to 500x400x300 | 0.1 / 0.5 / 1 | Full 3D with CAD integration | Small rubber/plastic parts inspection |

| CNC Video Measuring System | 100x100x100 to 500x400x300 | 0.1 / 0.5 / 1 | Automated 3D measurement, reverse engineering | Automotive and electronics metrology |

| FOV-Based Video Measuring Machine | 100x100x100 to 500x400x300 | 0.1 / 0.5 / 1 | 2D software, one-click measurement | High-volume plastic molding quality control |

| Hybrid Multi-Sensor System | Variable | 0.1 | Touch, laser, and video integration | Complex rubber seals in oil & gas |

This table highlights how Sipcon’s VMMs cater to diverse needs, with consistent high-resolution least counts ensuring precision across the board.

Video Measurement System Metrology in Industries

Video measurement system metrology is increasingly becoming the standard in industries where accuracy is crucial. For instance:

- Automotive – Verifying that engine parts and sensors are within tight tolerances.

- Electronics – inspecting circuit boards, connectors, and plastic casings.

- Rubber & Plastics – measuring seals, gaskets, and molded parts.

- Machining & Tooling – Verifying precision-cut metal parts

With a Sipcon VMM, companies can perform these tasks faster and with higher confidence than with manual methods.

Choosing the Right Video Measuring Machine

When selecting a VMM, consider these factors:

- Measurement range and precision

- Compatibility with materials (rubber, plastic, metal)

- Software capabilities (report generation, automation)

- Ease of maintenance and local service availability

A reliable video measuring machine manufacturer like Sipcon ensures that you get a system tailored to your industry’s needs.

FAQs About VMMs

- What is the least count of a VMM machine?

The least count of a video measuring machine refers to its smallest measurable unit. Sipcon VMMs can measure down to 0.001 mm, providing high precision for critical applications. - How does a video measuring machine work?

A VMM works using optical cameras, lighting, and motion control to capture images of a part. Software then analyzes these images to calculate dimensions accurately without physical contact. - Can VMM machines measure rubber and plastic parts?

Yes. VMMs are suitable for video measuring machines for rubber parts and plastic parts, providing non-contact measurement that prevents deformation. - Who are the leading vision measurement systems manufacturers?

Leading manufacturers include Sipcon, Mitutoyo, and Keyence. Sipcon provides tailored solutions for industries across Saudi Arabia with strong local support.

Final Thoughts on Video Measuring Machines

In Saudi Arabia, industries that focus on quality and precision are increasingly relying on video measurement machine. Whether it is video measuring machine for rubber parts, plastic components, or metal parts, Sipcon VMM offer unmatched accuracy, speed, and reliability. By adopting these systems, companies can minimize errors, improve product quality, and maintain competitiveness in a demanding market.![]()

Investing in a Sipcon VMM is not just buying a measurement machine; it’s investing in confidence, efficiency, and superior quality control.

Video Measuring Machine Price / Contact

📞 +91 9215699661

📧export@sipconinstrument.com

Enhance your quality control today with Sipcon VMMs. Ensure every product meets the highest standards, reduce inspection errors, and boost productivity. Contact our experts now for consultation and pricing!