Why Italian Industries Rely on Cutting Tools Measurement Systems for Accuracy

The vehicle manufacturing, aerospace, precision engineering, and manufacturing industries have long been known in Italy due to their craftsmanship, innovation, and attention to detail. Accuracy in machining and production is, therefore, something that can never be compromised to retain this reputation and compete globally. Even a slight change in the cutting tools could cause inefficiencies, increased costs, and poor quality of the products. Here, a Cutting Tools Measurement System becomes a very important part.

These are high-tech systems beyond quality-control tools. They make sure that cutting tools employed in production are accurate, constant and prepared to give their best-it has an immediate effect on productivity, tool life and integrity of final products. To maintain high standards in their machining practices, Italian manufacturers are gradually moving toward the use of cutting tools inspection systems, such as universal cutting tool measuring tools and cutting tool microscopes.

Changing the Quality Requirements in Italian Manufacturing

The industrial environment of Italy is characterized by the emphasis on high-quality products, such as luxury cars, aerospace equipment, mechanical components, and machinery. In these types of industries, there is no room to be vague; accuracy is the cornerstone of reliability and effectiveness.

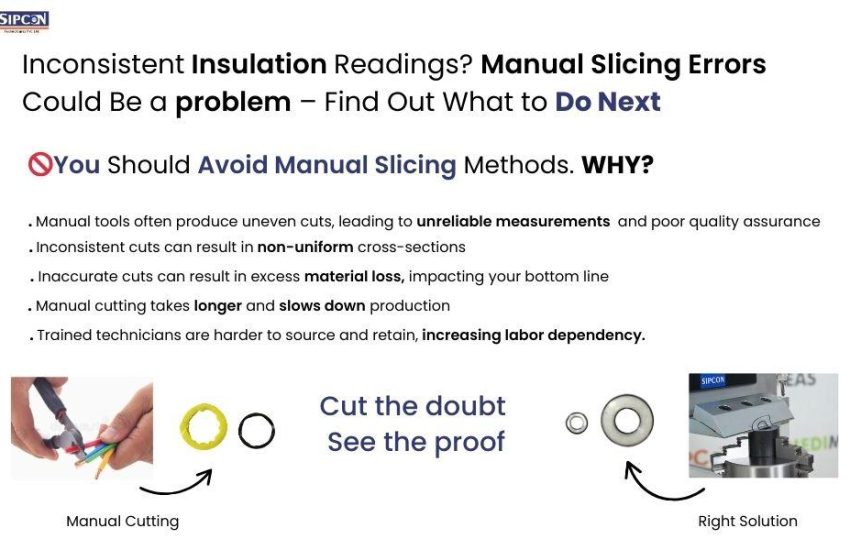

The traditional manual methods of inspection fail to deliver in this high-precision environment. Using manual gauges and visual inspections creates variability, wastes time, and can cause important tool wear or misalignment to be overlooked. Rather, developing manufacturers are adopting Cutting Tools Measurement Systems which integrate optics, sensors and software algorithms capable of providing accuracy within the micron range in real-time.

Not only do these systems monitor, but they also deliver useful data, which operators can use to effect instant changes and prevent expensive downtimes.

Role of Cutting Tools Measurement Systems

An Italian industry’s Cutting Tools Measurement System is a complete system to check that tool geometry, tool alignment and tool wear are within specified limits.

There are a few roles that these systems play:

There are a few roles that these systems play:

Dimensional Accuracy Check – Checks whether tools such as drills, milling cutters, and inserts match specific geometric requirements.

Wear Recognition – Identifies wear and tear at the onset and cancels defective machining operations.

Alignment Checks – Ensures that machines have the right tools installed, which enhances stability in the processes.

Documentation and Traceability – Prepares an electronic account of inspection, which is used in the audit of compliance and quality.

These systems enable the Italian manufacturers to reduce or eliminate rework, increase the life of their tools, and maximize efficiency through the integration with production lines.

The Major Tools That Promote Precision

One-size-fits-all solutions are not being depended on by Italian industries. They instead use special inspection equipment, according to the production situation.

Universal Cutting-Tool Measuring Instrument

A universal cutting tool measuring instrument will be a versatile type of measuring instrument that can measure a large number of tools. It gives very precise data about tool length, diameter, angles, and wear. In the case of manufacturers with a wide range of products in their line, this tool will provide uniformity in the various machining operations.

Cutting Tools Inspection System

The cutting tools inspection system combines precision optics with sophisticated software and allows checking the cutting tools at several checkpoints quickly and reliably. It reduces dependence on the operators, provides less human error and repeatability.

Cutting Tool Microscope

A cutting tool microscope enables the edges, coating, and wear patterns of the tools to be visually observed in great detail. It is an essential tool in industries where safety and performance can be affected by even tiny irregularities, such as those in the aerospace and automotive industries.

In combination, these tools create a strong quality control system that Italian manufacturers can use to stay competitive at the global level.

Advantages of introducing Cutting Tools Measurement Systems

In the case of Italian industries, the benefits of these systems extend more than accuracy:

- Increased Productivity – Time is saved on machines running with real-time inspection that reduces unproductive downtime.

- Less Scrap and Rework – Since tool defects are detected early, there is no scrap or expensive reprocessing.

- Consistency Quality– High repeatability- Each product is manufactured according to strict specifications.

- Long Tool Life – Tracking wear ensures tools are replaced on time and unwarranted tool expenses are eliminated.

- Traceability and Compliance – Digital records are compatible with quality management tools, such as ISO, to drive audits and customer confidence.

This not only contributes to profitability but also enhances the status of Italy as a centre of quality manufacturing.

Italy Tool Inspection Future

With the emerging trend of Industry 4.0, more Cutting Tools Measurement Systems are becoming smarter, connected, and predictive. The systems that Italian manufacturers are embracing have:

- AI-Powered Defect Detection – The use of machine learning to detect wear patterns of tools exceeding the pre-defined thresholds.

- Cloud-Based Data Management – Monitoring of data in multiple facilities.

- Connection via CNC Machines – Full integration with machine tools to provide automatic corrections of measurement systems.

- Predictive Maintenance – Anticipate failures in machines and repair them before they happen, minimizing unplanned downtime.

These changes are consistent with the long-standing tradition of innovation in Italy, which enables industries to plan ahead of their time and provide high-quality products to consumers worldwide.

Sipcon: Accurate Solutions to Italian Cutting Tool Manufacturing Industries

Italian industries that require precision measurement partners to remain competitive. Sipcon Instrument offers modern industrial Cutting Tools, Measurement Systems, cutting tools inspection systems, and cutting tool microscopes. Sipcon is highly focused on innovation and reliability; thus, manufacturers are not only assured of accuracy but also efficiency and scalability in their processes.

Investment in appropriate measurement systems is no longer a choice in industries that aim to achieve the utmost level of precision and performance.

👉 Call us today at +91 9215699661 or email export@sipconinstrument.com to discover how our advanced Cutting Tools Measurement Systems can boost accuracy and efficiency in your Italian manufacturing operations.