Camera Based Profile Projector (USA) for accurate dimensional inspection of delicate parts—fast, sharp, and reliable results every time

Even illumination offers perfect shadow of part for the reliable measurement effortlessly with sipcon profile measuring machine

Threadless stage ensures smooth, friction-free movement for long-term precision and effortless, accurate component inspection

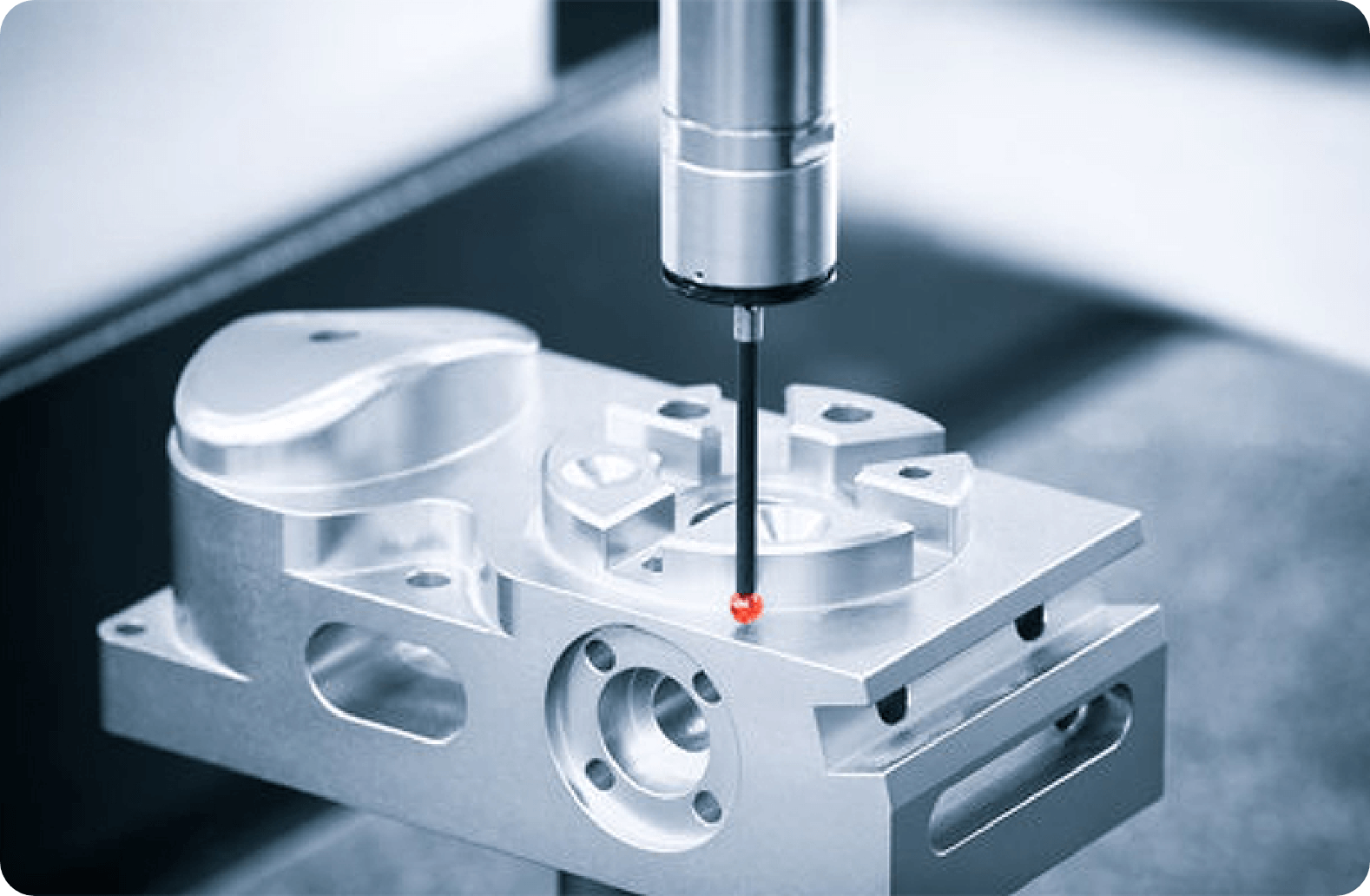

Explore our full range of Dimensional Measurement solutions in USA industries to get unmatched accuracy

Explore the whole range of SIPCON - 2D/ 3D profile projector, video profile projector, digital profile projector, horizontal profile projector and vertical profile projector etc

An Expert guide by your leading Camera-Based Profile projector manufacturer/supplier to help you make the right buying decisions