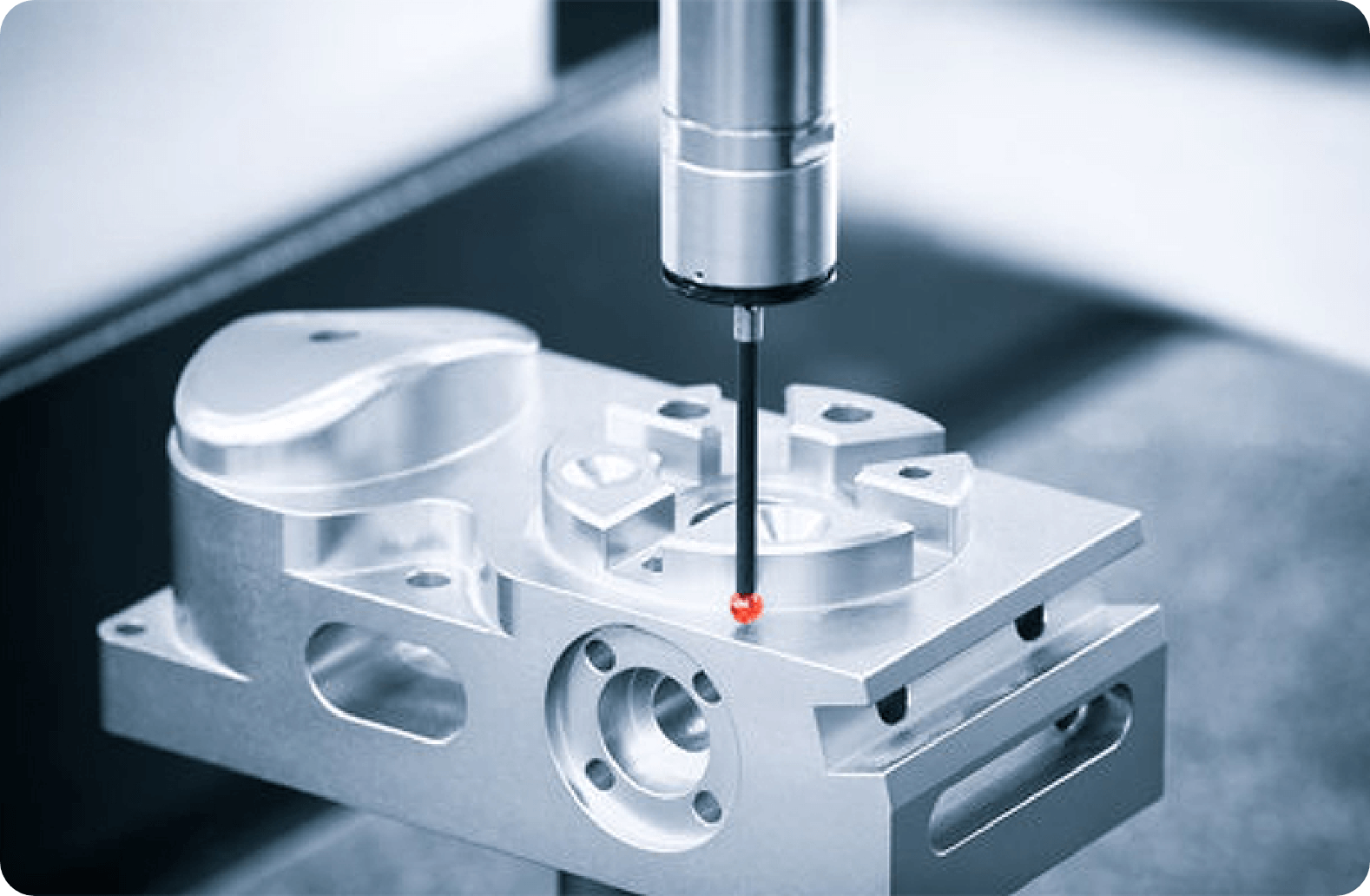

Discover all our dimensional measurement solutions in a single comprehensive guide

Explore our measurement solution from top Fov video measuring machine manufacturer/Supplier

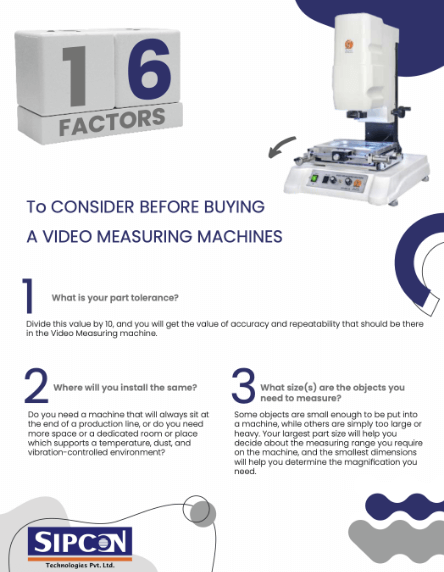

Key factors you must consider before choosing a right FOV video measurement machine