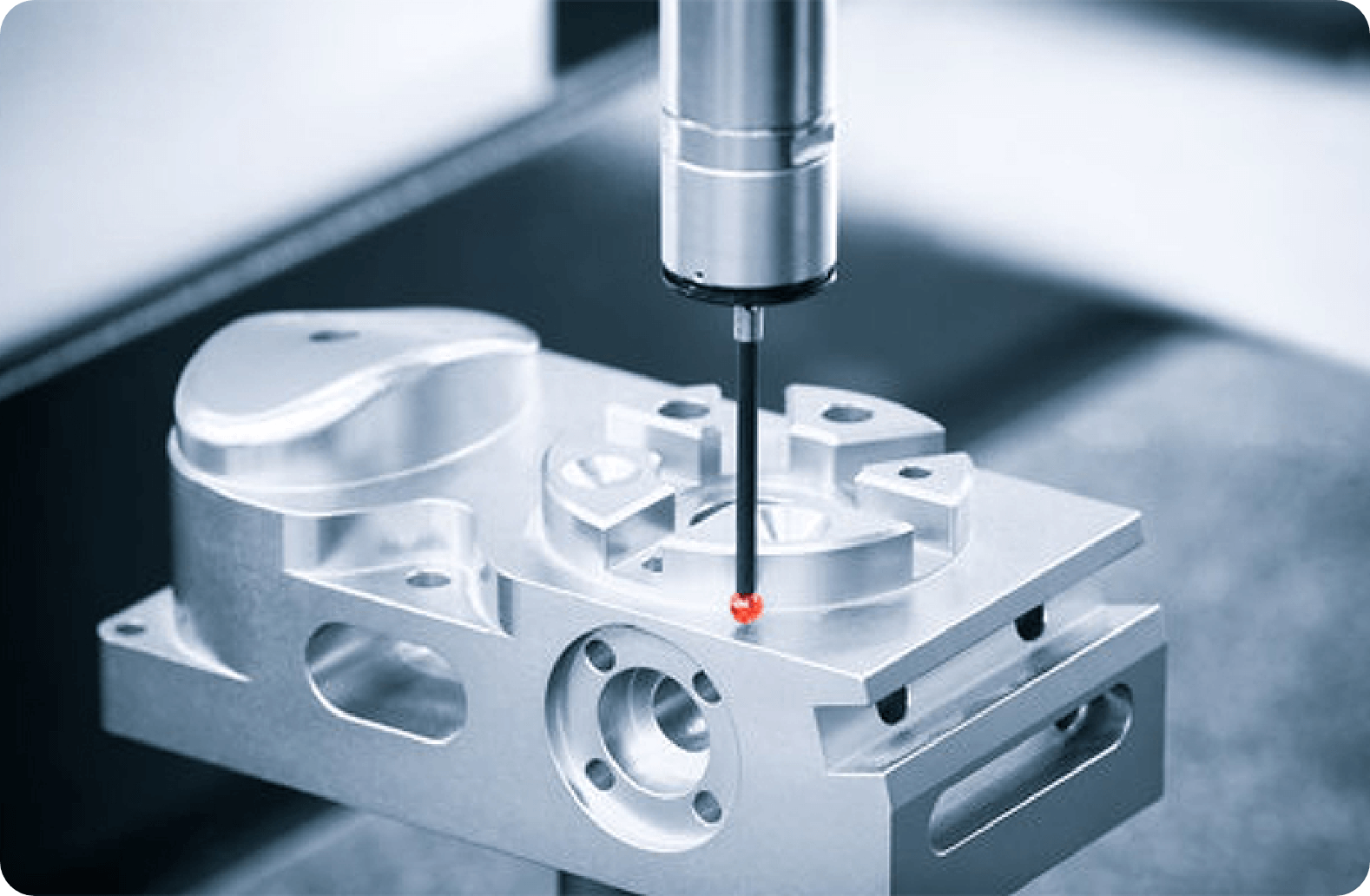

High-precision Multi-Sensor CNC Video Measuring System for rubber and plastic parts, from a leading cnc machine manufacturers in USA

Three advanced measurement technologies in one system - Vision measuring system which is ideal for high-speed 2D inspection and touch probe for 3D measurements

Achieve multi-angle inspection automatically with our video measurement machine’s Rotary indexer

The solid granite base and platform provide exceptional stability, minimizing vibrations and thermal distortions during measurement.

Explore our complete range of solutions by top leading video measuring machine manufacturers.

Discover our video measurement machine catalogue for precise, complete measurements

Buying guide to help you choose the right system by a trusted Multi-Sensor CNC Inspection System Manufacturer