How Vision Measuring Systems from SIPCON Are Helping Indian Manufacturers

Whether a factory is located in Rajkot, Faridabad, Coimbatore, Pune, Chennai, Hosur, Sriperumbudur, or thousands of MSME clusters across India, concern is same for every owner and quality manager, “What if the customer rejects the batch?”

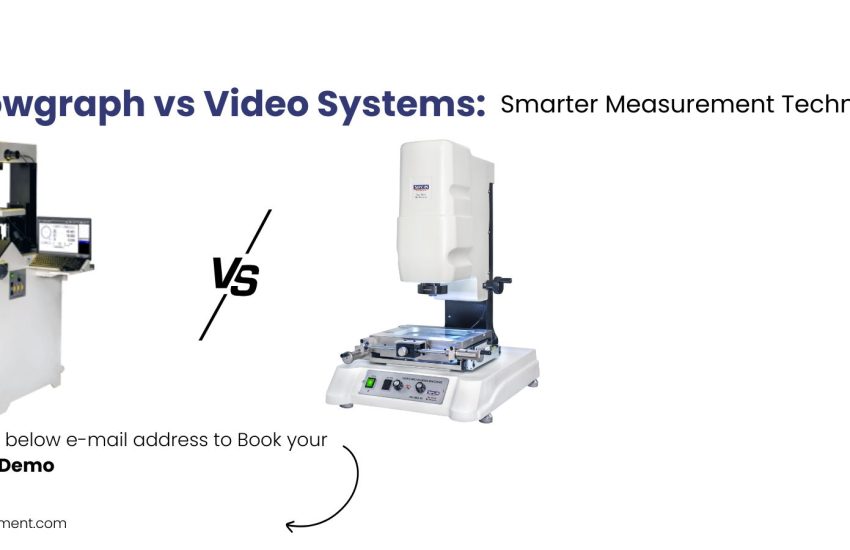

In today’s manufacturing environment, even a micron-level deviation can wipe out weeks of profit. Most Indian factories started their quality journey with Vernier calipers, micrometers, vertical measuring sizes and profile projectors. For years, these tools were enough especially when supplying to the replacement market or lower-tier customers.

That reality has changed.

Directly selling to the top OEMs and international brands globally connect with the world’s high-demand markets in Europe, Japan and the USA. Quality Control Inspections must not be done alone, since manual inspections cannot provide adequate consistency, or help fulfill required documentation, to ensure a successful production run of large quantities.

To meet this challenge, Indian-made SIPCON Vision Measuring Systems provide manufacturers with enhanced capabilities to support and strengthen their quality assurance processes on the shop floor.

Why Vision Measurement System Has Become Essential

Modern components are becoming smaller, more complex, and tighter in tolerance. When it comes to measuring features like radii or chamfers or profiles or soft/flexible (manufactured material), it is hard and often unreliable to use conventional contact measurement tools to measure these features accurately.

Vision measuring systems, on the other hand, enable manufacturers to inspect a single set of dimensions in near real-time, without having any contact with the part being inspected, and with very high levels of repeatability. For many businesses focused on reducing their rejection rates or improving their control of the manufacturing process and meeting the requirements of their customers’ audits, vision measuring systems provide a very practical solution.

Why Indian Manufacturers Prefer SIPCON Vision Measuring Systems

With decades of experience in precision measurement, SIPCON has developed vision systems specifically suited for Indian manufacturing conditions.

- Designed to Fit into Real Manufacturer’s Environment

Factories in India actually have to deal with dust, oil mist, temperature changes, fluctuating power supplies, and operators with many different levels of experience operating the equipment.

SIPCON systems are built with robust granite bases, protected guides, stable electronics, and user-friendly software that supports local language operation. The focus is on reliability, not delicacy.

- Fast Measurement with Practical Investment Levels

SIPCON vision systems can measure dozens of dimensions in seconds with micron-level repeatability. This speed allows inspection to keep pace with production without creating bottlenecks. Compared to imported alternatives with similar performance, the overall investment remains more accessible for Indian MSMEs.

- Reduced Operator Dependency

Through the use of automated edge detection capabilities and programmed measurement methods, you can produce equal and repeatable results no matter the operator’s background. Once a programming file has been established, repeat outputs for an individual part will be the same all the time and will therefore eliminate operator error due to personal judgment.

- Capability to Measure Complex Features

From thin rubber components and transparent plastics to deep bores and micro-machined metal parts, SIPCON’s optical systems and lighting options allow accurate inspection without damaging delicate components.

- Digital Reporting and Traceability

Digital creation of the measurement data, measurement tolerances, photos, and inspections helps maintain better traceability, allows easier auditing, provides easier integration into quality systems and ERP systems.

Real Impact Seen on Indian Shop Floors

Across different industries, manufacturers have used vision measurement to solve long-standing quality challenges.

In automotive and engineering applications, consistent inspection of chamfers, profiles, and angles has helped reduce customer rejections significantly. Medical and precision component manufacturers have improved inspection speed while meeting strict audit requirements. In several cases, companies have reduced dependence on manual inspectors while improving accuracy and documentation.

The common outcome has been better control, faster decision-making, and increased confidence when supplying to demanding customers.

Service and Support That Matters

Measurement systems are long-term investments. Along with a machine, support behind a machine equally matters. In India, SIPCON as an original equipment manufacturer (OEM) along with on-hand availability of spare parts, minimizes downtime, ensuring that production continues without interruptions.

For manufacturers, this reliability often becomes a deciding factor during system selection.

Supporting MSMEs with Subsidies and Flexible Financing

Many Indian manufacturers are able to access central and state government subsidies for quality improvement and capital equipment. Vision measuring systems often qualify under these schemes, making advanced inspection technology more accessible.

Flexible financing options further help MSMEs upgrade quality without placing excessive strain on cash flow.

In a competitive manufacturing environment, quality is no longer defined only by machining capability. It is defined by how accurately, consistently, and confidently a company can measure what it produces.

When manufacturers invest in proper vision measurement systems, they are not only decreasing their rejection rates but increasing their customers’ trust in them and improving their own process and positioning for future growth.

With tighter tolerances becoming standard and increased customer requirements, if your current inspection systems fall short in meeting these stringent standards, then it is advisable to consider vision measurement for the first time. Because in today’s manufacturing world, the companies that measure better are the ones that grow faster.