Part Genie: Catch the Microns You Can’t See, Before They Cost You

Why Traditional Part Inspection Fails?

2D part inspection still relies on automation scripts, fixture tools, and manual decision-making in thousands of quality labs because, in modern manufacturing, getting a part “just right” is not about rough alignment or a visual match with a drawing.

It is about sub-micron precision, geometric integrity, and measurement accuracy, because every contour of a part can affect how a system performs.

One of the weakest links and the cost of that link often shows up weeks later in assembly or customer rejection

Why Measuring a size is not Enough?

No part ever fails at the time it is measured. It fails where you did not.

A bore that’s 0.03 mm not perfectly centred may not raise alarms in a rush. But when that same bore is meant to align with another mating part suddenly, you are troubleshooting a misfit, re-machining, or worse, rejecting the entire batch.

Most QA teams record them for quality verification. That is not confidence. That is guesswork.

Image-Based Part Validation

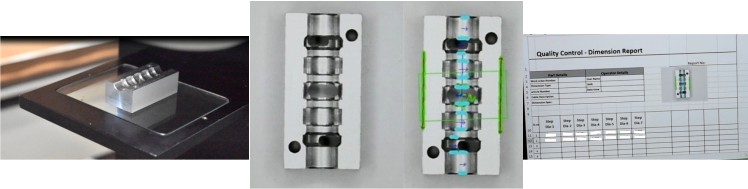

Image-based inspection systems, like those commonly used in manufacturing, do not check inspection. Instead, they look at the entire geometric story.

Each arc, border, opening, and pitch is scanned not just visually, but dimensionally. Measured against actual tolerance values. Logged with full traceability.

No macros. No manual benchmarks. No “maybe it’s close enough.”

The Hole They Missed resulted leading to losses (Case Study)

One of our tier-1 vendors supplying support elements had passed their parts in incoming inspection using profile projectors. But during assembly, the fasteners were not aligning.

A single hole had drifted by 0.12 mm. That is less than the depth of two human hairs.

Callipers and macros did not flag it, but the downstream cost was real:

- Line stoppage

- Rework

- Late delivery

- ₹3.8 lakh in cumulative losses over 30 days

Switching to a non-contact image-based system caught it in the first batch.

Why Is 2D Profile Deviation Invisible?

You cannot see concentricity with the naked eye. You unable to determine pitch drift with measuring stick

You cannot “feel” an angular mismatch unless the part is put together.

And you should not have to.

That is the role of high-resolution digital microscopy and real-time vision measurement systems. These systems do not just show the shape they quantify the shape, in under 3 seconds.

Common Errors Missed in Conventional Inspection

Even the comprehensive inspection can miss:

- Concentricity drift in multi-bore parts

- Roundness irregularities in stamped features

- Pitch and gap errors in fine geometries

- Angle deviations that affect fit and function

- Parallelism shifts over long part lengths

And if you are using printed drawings and profile projectors, chances are some of these are not being measured at all.

Why Geometry-First QA Wins?

The future of inspection does not start with callipers; it starts with data. And geometry is data. Rich, layered, accurate data.

With Part Genie-style systems, you get:

- One-click inspection – No macros, just position and click

- DXF overlay – Aligns digital drawings in real time

- 360° orientation compensation – No need for part alignment

- Measurements per feature – Precision across every angle

- Pass/fail batch reports – Color-coded, auto-exportable

Whether you are measuring straightness, roundness, parallelism, or true position, it is done in seconds, with no operator dependency.

Where Part Genie Shines

- Tool & Die validation: Rapid changes do not need new macros.

- Sheet metal QA: Flat, complex parts that are identified with no fixture changes.

- High-mix, low-volume: Run different parts in the same shift requires no preparation

Our Client Says;

“I no longer worry about which 3 holes for measurement. Now It will check faster than I used to check one.”

– QA Lead, Pune-based Precision Shop

Conclusion and CTA

Every micron matters. Especially the ones you do not see.

Explore Part Genie here and see how modern geometry-based inspection can change your QA.

Numbers do not lie with 3-second inspection cycles, ±3 µm accuracy, and automated reporting. Part Genie transforms inspection from a bottleneck into a business advantage. Clients have reported saving lakhs in rework, reclaiming production hours, and improving customer confidence, all because geometry is no longer a guess. Part Genie protects your reputation by catching errors before they ever leave the QA floor.

📞 Contact us now at info@sipconinstrument.com to schedule a demo and see how 5-second inspections can transform your QA process.

Visit https://www.sipconinstrument.com/

Contact Number – 91-8222929966