Best Die Inspection Microscope Manufacturers & Suppliers in Italy

Introduction

In Italy’s wire-drawing and cable production sectors, one principle has always remained true: the quality of the drawing die largely dictates the accuracy, stability, and surface finish of the final wire. Because of this, every die used in the process needs to be examined with absolute precision.

A standard microscope is no longer enough for today’s manufacturing expectations. Italian producers now look for instruments that can clearly reveal the highly polished internal surfaces of a die, show geometry without distortion, and expose even the smallest flaws. This shift is the reason advanced die inspection microscopes—especially those built with indirect illumination, refined optics, and controlled zoom—have become the preferred choice in the industry.

Over the past several years, many well-known wire-drawing plants in Italy discovered that traditional lighting systems simply cannot handle reflective die surfaces. They needed a practical, purpose-built solution. That gap was effectively filled by systems like the Drawing Die Inspector (DDI), which offer stable magnification, a clear visual field, and reliable geometry inspection designed specifically for wire-drawing dies.

If you’re evaluating options for the best die inspection microscope manufacturer or looking for a dependable supplier in Italy, the information that follows will help you understand the available technologies and choose the right system for your production needs.

Why Die Inspection Microscopes Matter in Italy’s Wire-Drawing Industry

In Italy, sectors such as automotive, aerospace, medical wire, electrical cables, and high-precision tooling depend heavily on consistent die performance. Even the smallest defect inside a wire-drawing die can:

- Increase wire breakage

- Create inconsistent diameters

- Reduce surface finish quality

- Slow down production

- Increase scrap and reworking

To avoid these expensive problems, Italian manufacturers rely on die inspection microscopes capable of revealing micro-imperfections in dies ranging from medium to ultra-fine sizes.

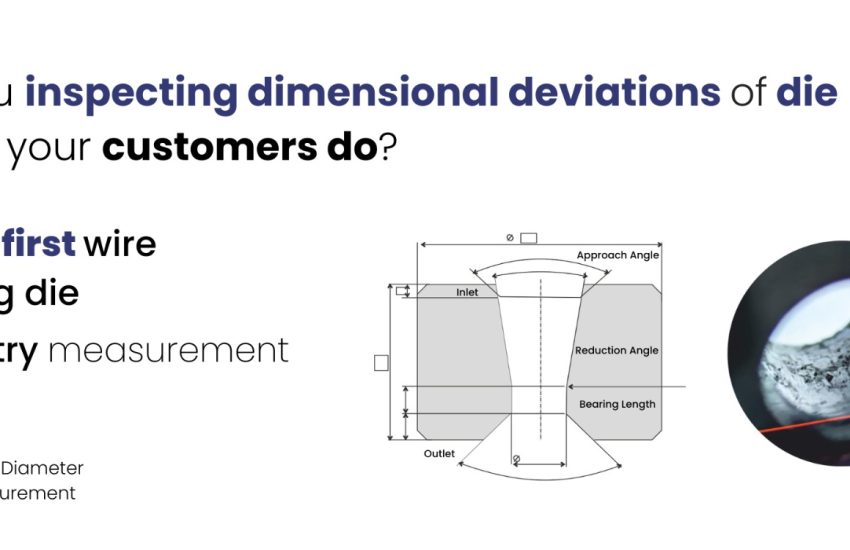

Core Challenges in Die Inspection

Traditional inspection methods used in many facilities show one common problem:

Highly polished and reflective die surfaces reflect direct light, causing a black field image.

As a result:

- micro-cracks become invisible

- pits cannot be detected

- geometry distortions remain hidden

- analysis becomes unreliable

This makes traditional lighting unsuitable for precise die inspection.

Italy’s industries have therefore moved toward microscopy solutions with diffuse illumination, controlled LED lighting, and multi-angle viewing, which make it possible to evaluate the die face, land, approach angle, and exit area clearly.

What Italian Industries Expect from a High-Precision Die Inspection Microscope

Italian manufacturers consistently look for:

- High-clarity visualization inside drawing dies

- Detailed inspection of approach angle, bearing, reduction zones

- Adjustable illumination without glare

- Reliable depth perception

- Large working distance for handling dies

- Capability to inspect dies down to 30 microns

- Durable construction suitable for industrial use

This demand has created a competitive environment among global and Italian suppliers where only highly engineered solutions are preferred.

The Rise of Modern DDI (Drawing Die Inspector) Technology

The DDI (Drawing Die Inspector) has become a preferred microscopy technology for die inspection across Europe and Italy due to its:

- Indirect and diffuse illumination

- Large zoom range

- High-resolution digital output

- Ability to analyze ultra-fine dies

- Ergonomic viewing head

Unlike conventional microscopes, the DDI is specifically built for wire drawing dies, ensuring that every inner surface can be viewed clearly and without eye strain.

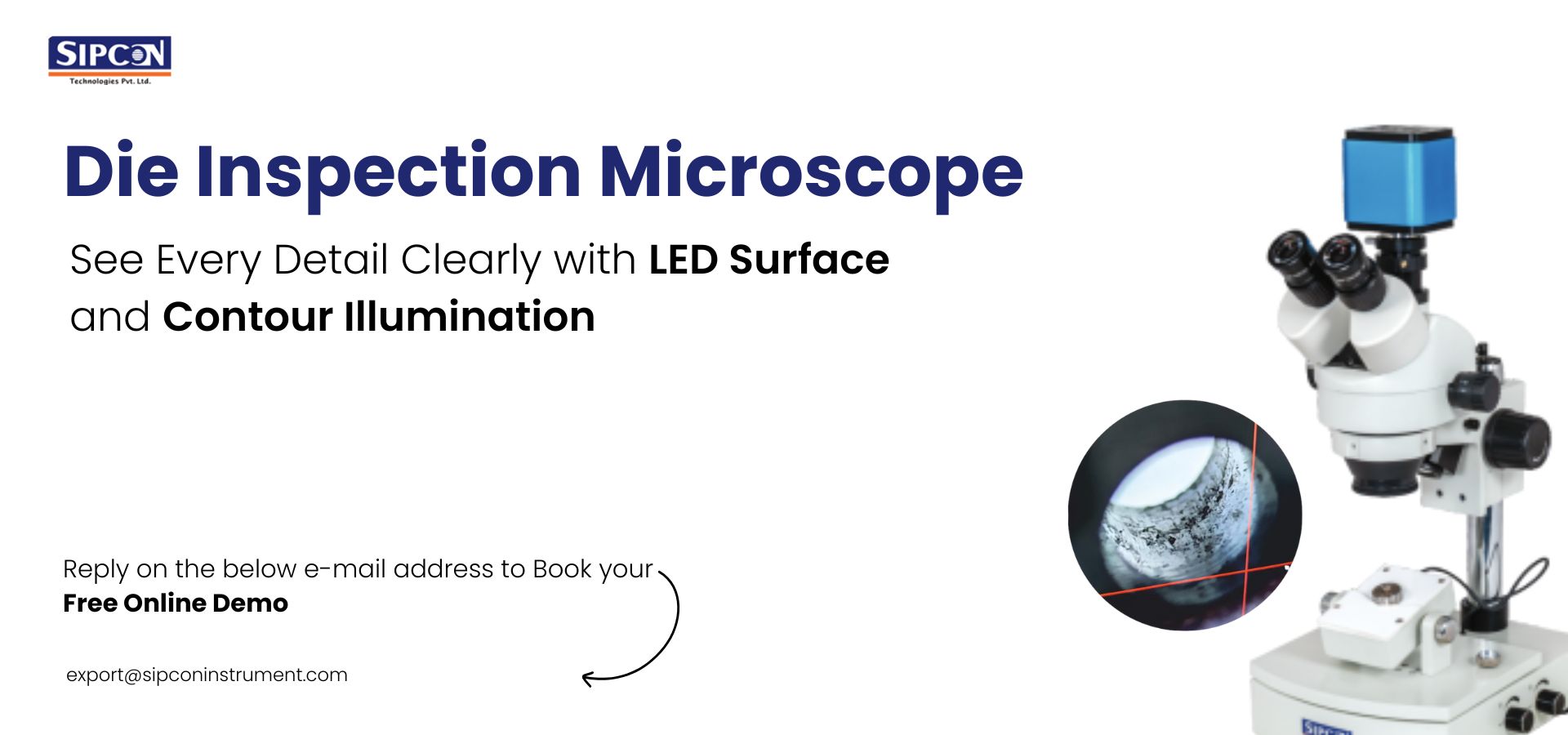

Key Features of a Reliable Die Inspection Microscope

A professional die inspection microscope in Italy typically includes:

- Trinocular observation for simultaneous viewing and digital imaging

- 10X/20X compensating eyepieces

- 5MP high-resolution vision module

- 0.7X–4.5X objective lens

- 7X–45X magnification, extendable to 14X–90X

- LED surface and contour illumination

- Metal base construction

- Minimum die inspection up to 30–50 microns

- Rotatable die geometry observation

These specifications allow quality control teams to inspect medium, fine, and ultra-fine dies with clarity.

SIPCON’s DDI – A Global Supplier for Die Inspection Microscopes in Italy

Among the prominent global players supplying precision measurement instruments, SIPCON stands out as a major name frequently trusted by Italian wire-drawing and cable industries.

SIPCON’s Drawing Die Inspector (DDI) is developed specifically to address the problems of reflective die surfaces and inconsistent lighting. When Italian manufacturers evaluate suppliers, SIPCON’s DDI is considered a benchmark because of its:

- precision optical system

- innovative illumination

- durable build

- industrial-grade performance

- compatibility with ultra-fine dies

- ergonomic operation

For companies seeking a dependable die inspection microscope manufacturer or supplier in Italy, SIPCON’s DDI has become a preferred choice due to its reliability and clarity.

Technical Specifications of the Drawing Die Inspector (DDI)

Optical System

- Observation Head: Trinocular

- Eyepiece: 10X/20X compensating

- Objective Lens: 0.7X – 4.5X

- Magnification: 7X–45X (extendable to 14X–90X)

- Vision System: 5MP digital module

Illumination

- Surface Illumination: LED

- Contour Illumination: LED

- Diffused Indirect Lighting: Eliminates glare and improves visibility

Mechanical & Functional Features

- Working Distance: 90 mm

- Max Die Diameter: 12 mm

- Min Die Diameter: 50 microns (30 microns optional)

- Metal Base Construction

- Fully Manual Operation

- Rotatable Die Geometry Inspection

These specifications make the DDI suitable for all levels of die inspection—from routine quality checks to advanced precision analysis.

Advantages of Diffuse/Indirect Illumination

Diffuse illumination is the heart of SIPCON’s DDI system. Italian industries prefer this system because it offers:

1. Reduced Specimen Damage

No harsh direct lighting → protects delicate ultra-fine dies.

2. Enhanced Contrast

Fine surface structures become visible, even at high reflectivity.

3. Minimization of Glare

Removes reflection problems commonly seen in mirror-polished dies.

4. Improved Surface Finish Evaluation

Operators can analyze cracks, pits, scratches, bearing surface quality and reduction zones clearly.

5. Comfortable Viewing

No eye strain, even during long inspection cycles.

With these advantages, DDI systems are now widely used by Italy’s leading wire producers.

Applications Across Italian Wire, Cable & Metallurgy Sectors

In Italy, the die inspection microscope is used extensively across:

- Wire drawing units

- Cable manufacturing plants

- Fine and ultra-fine wire producers

- Metallurgy and material testing labs

- Tooling & die refurbishment centers

- Automotive wire component manufacturers

- Steel wire & alloy wire industries

The DDI microscope supports inspection of:

- Diamond dies

- PCD dies

- Tungsten carbide dies

- Shaped dies

- Multi-wire dies

- Ultra-fine wire drawing dies

Buyer’s Guide – How Italian Companies Choose a Die Inspection Microscope

When Italian engineers evaluate die microscopes, they typically consider:

1. Illumination Quality

Diffuse LED is preferred for glossy die surfaces.

2. Zoom Range

Should cover medium to ultra-fine dies.

3. Digital Output

5MP or higher for documentation.

4. Ergonomics & Comfort

Trinocular head reduces eye fatigue.

5. Durability

Metal base and industrial design are essential.

6. After-Sales Support

Suppliers who understand die geometry and wire drawing processes are valued highly.

Why SIPCON Is Considered Among Top Die Inspection Microscope Manufacturers Supplying to Italy

SIPCON is recognized worldwide for its measurement and inspection instruments. For Italian markets, customers prefer SIPCON’s DDI because:

- It is purpose-built for die inspection

- It uses indirect illumination, perfect for reflective surfaces

- It offers stable and sharp optical clarity

- It reduces operator fatigue

- It supports fine to ultra-fine die inspection

- It has strong technical specifications tailored for industrial QC

- It delivers consistent results

- It is supplied with reliable global support

While Italy has local suppliers and distributors, SIPCON stands out as a global manufacturer trusted by Italian buyers for die quality evaluation.

Conclusion

The demand for precision in Italy’s wire-drawing and cable manufacturing industry continues to increase. High-performance dies require equally advanced inspection tools.

A die inspection microscope equipped with diffuse LED illumination, superior optical clarity, and ergonomic design is essential for consistent quality control. Among global suppliers serving Italy, SIPCON’s DDI remains a leading choice because of its technical superiority, industrial reliability, and ability to reveal even the smallest imperfections inside drawing dies.

If you are evaluating die inspection equipment for your facility in Italy, the DDI offers the accuracy, comfort, and long-term performance needed for modern wire-drawing operations.

FAQs

1. What is a die inspection microscope?

A die inspection microscope is a specialized optical instrument designed to inspect the internal surfaces, geometry, and finish of wire-drawing dies.

2. Who is the best die inspection microscope manufacturer supplying to Italy?

Among global manufacturers, SIPCON is widely regarded for supplying advanced Drawing Die Inspector (DDI) systems to the Italian market.

3. Why is diffuse illumination important in die inspection?

Diffuse lighting eliminates glare and black-field reflections on polished die surfaces, making internal defects clearly visible.

4. Can these microscopes inspect ultra-fine wire drawing dies?

Yes. Systems like the DDI can inspect dies as small as 30–50 microns.

5. What industries in Italy use die inspection microscopes?

Wire drawing plants, cable manufacturers, precision metalworking units, automotive suppliers, and research labs.

Ready to Upgrade Your Wire-Draw Die Inspection?

Looking for a reliable die inspection microscope manufacturer? SIPCON’s Drawing Die Inspector offers precision, glare-free illumination, and accurate geometry inspection for medium to ultra-fine wire-drawing dies. Perfect for Italian wire-drawing and cable industries, our die inspection microscope ensures superior quality and consistency in every production run.

Contact SIPCON today to learn more about our die inspection microscope in Italy, request a demo, or get a personalized quotation.

📞: +39 340404 2357

✉️: export@sipconinstrument.com

📍: Via Brigata Julia, 21, 35020 Pernumia PD, Italy