Measurement of Drawing Die Italy introduction Precision and Accuracy

In Italy, precision wire, cable and metal forming industries, the worlds of precision must dominate. Any deviation from the die’s true geometry can compromise quality, introduce scrap and, often, force a delay in production schedules. This is why drawing die geometry measurement has become a major driver to businesses today. With a latest drawing die measurement machine, 3D profiles systems and drawing die inspector Italian suppliers ensure a safe and consistent output quality and meet the rigorous European norms.

1. Why Italy Requires High-tech Measurement Solutions for Drawing Dies

Leave it to the Italians to mind specifics. The geometry of a die, like diameter, ovality, reduction angle and bearing length affects Uniformity of wires and cables conductivity and waste byproduct thereof.

The creation of accurate measuring systems for drawing dies conduce to:

- Reduce scrap and rework

- Minimize downtime

- Maintain consistent process parameters

- Boost overall production efficiency

With a growing number of SMEs in Italy engaged with high-end precision manufacturing, the necessity of metrology and QC equipment is higher than ever. Smart, of course, making it clear why you should be investing in high-precision measurement systems to adopt equipment that supplies high-precision measurement is a poor decision that is dumb.

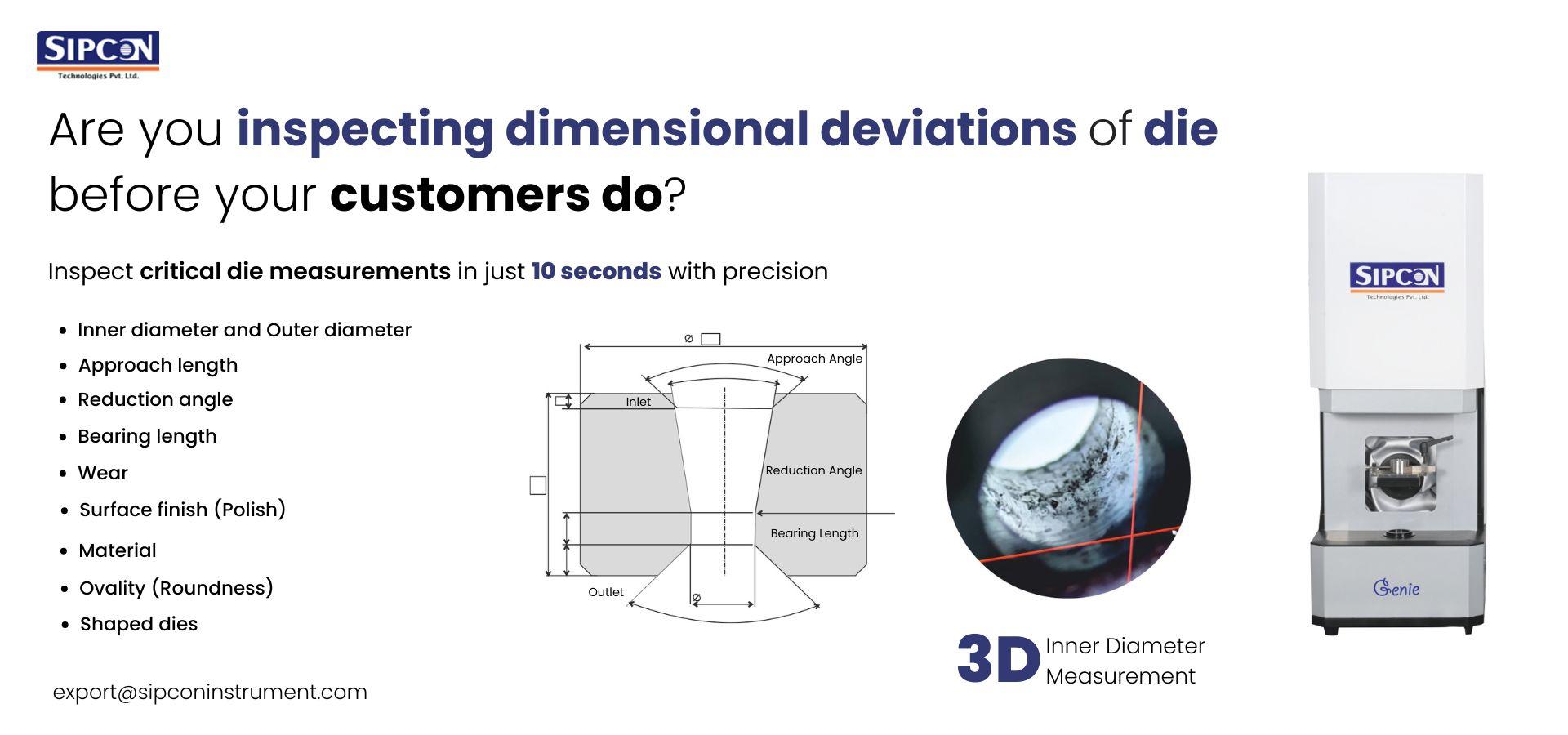

2. Measurement of drawing die geometry – what and why?

Quality of wire and cable manufacture relies on careful time-to-time inspection of the following parameters Wire & Cable Die maintains:

- Diameter: Fulfilled all wires according to deliver precision in every measurement

- Ovality/Roundness: Uniform and without defects

- Reduction Cone Angle: Maximizes draw forces and material flow

- Bearing Length: Wire tensile strength and surface quality

- Transition Radius: Increases die life and performance

With the help of such measurement system to précised follow up these parameters, manufacturer can reduce minimal failures and be sure that wire & cable quality delivers consistent results

3. Wire Drawing Die Measuring Machines in Italy

There are many first class drawing die measurement machine made in Italy as follow:

- D-Lab (TKT Group (Konner / Areole): A contact-less, telocentric optical system for measuring die diameters from 0.5 to 8 mm with a wide array of ±1 μm in approximately ~1 second.

- DGMS from OEG Optical Metrology: A modular system that measures diameter; roundness; reduction angle and bearing length for both shaped & enamelling dies.

- Create DM100 / DM600S The latest generation profile measurement systems providing online click free bore diameter and ovality inspection with optical self-calibration, high repeatability.

These solutions allow Italian manufacturers to achieve precision and faster inspections

High Level Drawing Die 3D Profile Measurement Systems

Three-dimensional measurement of the die for complex die geometries is a must. With systems including the DM600S, details of the 3D profile of a die can be obtained in terms of bearing asymmetry and cone geometry.

Benefits include:

- Triggering Die wear pattern in Detail.

- Enhanced process control and lifecycle management

- Measurement of difficult internal geometry

- By adopting 3D profile measurement systems for drawing dies, Italian companies achieve the best accuracy and reliability.

4. Drawing Die Gauges and Automated Measurement System

Today’s drawing dies, inspectors make quality control automatic. To meet this demand tools have been introduced as follows from CompTIA with models CU4, CU6, CU11 and CU20; A willingness to listen to your needs Too!

- Automated die feeding and inspection

- Integration high-efficiency manufacturing lines operations

- Reduced operator workload

- Auto-mated die measurement systems not only have to be efficient, while securing a constant process towards quality.

5. Italian Suppliers & Manufacturers You Can Trust

There are experienced suppliers and reputable distributors delivering high-precision drawing die measurement systems Italy in. Selecting our partner ensures local support, swift response on service and compliance with EU excellence built into solutions specific to the Italian production environment.

- Italy: How to Select the Best Drawing Die Measurement System

- Consider the following to choose a measurement system:

- Measurement precision and speed

- 3D capabilities and real-time inspection

- Software aspects and user friendliness for operators

- On- site calibration, comprehensive training and dedicated Italian support

- Scalable or expandable systems that adjust accordingly to your production requirements change.

- Systems like DGMS deliver modularity, while D-Lab and Create deliver state-of-the-art 3d measurement performance, enabling Italian manufacturers to ramp up without the need to compromise on accuracy.

6. What can we expect for Italy in the future: Automation & Smart Metrology

Italian manufacturing is being reinvented by Industry 4.0. Due to the advanced measurement systems for drawing die, which are getting smarter every time, they can now be easily connected to ERP and production data, providing:

- AI-assisted die wear prediction

- Closed-loop die maintenance

- Increased traceability and certification for EU markets

- Embracing automation and predictive analytics is also that Italian companies maintain a competitive advantage while mitigating the risks associated with production.

- to record all data Ships with every model. 12.

General references

As per the studies showcased

https://en.wikipedia.org/wiki/Die_(manufacturing)

Conclusion & CTA

Accuracy in measuring drawing die geometry is necessary. Whether it is 2D, 3D full profile analysis or automated drawing die inspectors, Italian manufacturers have the latest technology today.

Explore solutions including D-Lab, DGMS, and Create for the consistent enhancement of die quality, with reductions in defects and efficiencies in production. Contact reliable Italian manufacturers to ask for demos or trials and experience the difference of precision measurement firsthand. Write to us at export@sipconinstrument.com or visit https://www.sipconinstrument.com/italy/ to start the conversation, connect with us at +39-3404042357