Drawing Die Measurement Systems in Saudi Arabia: Geometry, 3D Profile & Die Inspection Guide

Introduction to Drawing Die Measurement in Saudi Manufacturing

Saudi Arabia’s manufacturing sector is expanding fast especially in construction, oil & gas and infrastructure related production. With higher output demand manufacturers must keep dimensions accurate and quality consistent at every stage.

Drawing die measurement systems help achieve this by controlling die accuracy, reducing production issues, and supporting stable long term manufacturing performance.

What Is a Drawing Die Measurement System?

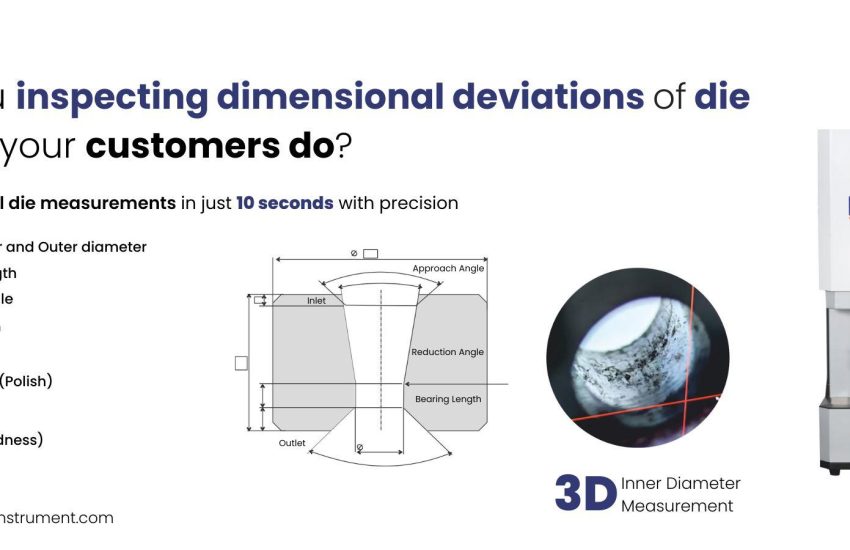

A drawing die measurement system is a specialized inspection solution designed to measure the internal geometry, profile, angles, and surface condition of drawing dies used in wire, rod, and tube drawing processes.

These systems help manufacturers to:

- Verify die dimensions before production

- Detect manufacturing defects and wear

- Ensure uniform material flow

- Maintain consistent product diameter and strength

In Saudi Arabia, automated drawing die measurement systems are widely adopted because they provide fast, repeatable, and highly accurate results compared to manual inspection methods.

Drawing Die Geometry Measurement: Why Accuracy Matters

Drawing die geometry measurement focuses on analyzing the internal shape and angles of the die. Even a small geometric deviation can result in poor surface finish, wire breakage, or excessive die wear.

Key Geometry Parameters Checked in Drawing Dies

- Entry angle

- Reduction zone geometry

- Bearing length

- Exit profile

For Saudi industries handling high-stress and heavy-duty applications, accurate geometry measurement ensures product durability and operational safety.

Common Geometry Issues in Drawing Dies

- Incorrect bearing length

- Uneven reduction angles

- Oval or distorted die profiles

- Accelerated wear due to misalignment

Early detection of these issues through precise geometry measurement reduces material waste and unplanned downtime.

Drawing Die 3D Profile Measurement System Explained

Traditional inspection methods only measure selected points, while a drawing die 3D profile measurement system captures the entire internal surface of the die.

How 3D Die Profile Measurement Works

- Non-contact optical scanning records the internal surface

- A complete 3D digital model is generated

- Software compares actual geometry with design specifications

Benefits of 3D Profile Measurement

- Full visibility of die wear and deformation

- Accurate trend analysis over time

- Predictive maintenance planning

- Extended die service life

High-volume manufacturing plants in Saudi Arabia increasingly rely on 3D profile measurement to maintain stable and repeatable production output.

Die Inspection Microscope for Precision Quality Control

Many die-related failures originate from microscopic surface defects that are invisible to the naked eye. A die inspection microscope is used to identify these issues before they affect production.

Defects Detected Using a Die Inspection Microscope

- Micro-cracks

- Surface scratches

- Polishing defects

- Coating damage

Optical vs Digital Die Inspection Microscopes

- Optical microscopes are ideal for quick visual inspections

- Digital microscopes provide high magnification, image capture, and inspection reports

Saudi manufacturers increasingly prefer digital microscopes for quality documentation and traceability.

Industries in Saudi Arabia Using Drawing Die Measurement Systems

Drawing die measurement and inspection systems are widely used across:

- Wire and cable manufacturing

- Oil and gas equipment production

- Automotive component manufacturing

- Construction material processing

- Heavy engineering and fabrication

These industries demand high reliability and consistent performance, making precise die measurement essential.

How to Choose the Right Drawing Die Measurement System in Saudi Arabia

Selecting the right system is a long term investment decision.

Key Factors to Consider

Measurement Accuracy and Resolution

Micron level precision is critical for quality control.

3D Profile Measurement Capability

Ensures complete inspection and future readiness.

Software and Reporting Features

Easy data analysis, comparison and documentation.

Local Support in Saudi Arabia

Reliable calibration, training, and service support reduce downtime.

Importance of Regular Drawing Die Inspection

Routine drawing die inspection helps manufacturers:

- Detect wear at an early stage

- Prevent sudden die failures

- Plan re-polishing and replacement schedules

Saudi manufacturers that follow preventive inspection practices achieve longer die life and lower operating costs.

Future of Drawing Die Measurement and Inspection in Saudi Arabia

Saudi Arabia’s manufacturing sector is moving toward automation and smart inspection technologies.

Future developments include:

- AI-assisted die analysis

- Real-time measurement systems

- Predictive wear monitoring

- Integrated quality control platforms

These innovations will further improve efficiency, accuracy, and cost control.

Why Saudi Manufacturers Are Investing in Advanced Die Measurement Systems

Advanced drawing die measurement systems help manufacturers:

- Improve product consistency

- Reduce rejection and rework

- Meet international quality standards

As a result these systems are becoming a strategic investment rather than just inspection equipment.

Frequently Asked Questions (FAQs)

What is a drawing die measurement system?

It is used to check the internal shape and condition of drawing dies so wire or rods are produced with consistent size and quality.

Why is drawing die geometry measurement important?

Because even small geometry errors can cause wire breaks, poor finish, and faster die wear.

What is a drawing die 3D profile measurement system?

It scans the full internal profile of a die instead of checking only a few points.

What is a die inspection microscope used for?

It helps identify microcrack, scratches and surface defects that are not visible to the naked eye.

How often should drawing dies be inspected?

Most manufacturers inspect dies during maintenance cycles or when wire quality starts changing.

Are these measurement systems used only for wire drawing?

No, they are also used for rod drawing, tube drawing, and other precision metal forming processes.

Why is local support important when buying die measurement systems in Saudi Arabia?

Local service and calibration support reduce downtime and keep production running smoothly.

Final Thoughts

In Saudi Arabia’s competitive manufacturing environment, drawing die measurement systems, geometry analysis, 3D profile measurement, and die inspection microscopes are essential tools for achieving high quality, low rejection rates, and consistent production performance.

Investing in the right die measurement solution enables manufacturers to improve efficiency, reduce costs, and maintain long term operational excellence.

Ready to Improve Drawing Die Accuracy and Production Quality?

If you are looking to improve drawing die measurement, geometry inspection or 3D profile analysis in your manufacturing process, working with the right inspection solution makes all the difference.

Whether your focus is reducing die wear, improving wire quality or minimizing production downtime, our team can help you select the right measurement and inspection system for your application in Saudi Arabia.

Get in Touch Today

Website:

https://www.sipconinstrument.com/sa/

Email:

export@sipconinstrument.com

Phone / WhatsApp:

+91 9215699661

Saudi Arabia Office:

Aba Al Khail Tower, 6th Floor Sitteen Street, Jeddah – Saudi Arabia

Our specialists work closely with manufacturers to provide reliable drawing die measurement systems, 3D profile inspection solutions, and die inspection microscopes tailored to real production needs.

👉 Contact us today to discuss your requirements and take control of die quality and production consistency.