How Sipcon Profile Projectors Are Powering Precision Engineering across Australia

Introduction

In precision engineering, accuracy decides success. From aerospace to automotive and electronics, manufacturers need tools that can measure components with micron-level precision. One of the most reliable instruments for this is the profile projector (also called an optical comparator).

Among the leading names, Sipcon profile projectors have gained popularity throughout Australia due to their reliability, precision, and cost-effectiveness.

This blog covers everything you need to know: profile projector diagram, working principle, uses, advantages and disadvantages, least count, types (Optical, 2D, 3D, Video, Camera-Based), price, calibration, and FAQs.

What is a profile projector?

A profile projector is an optical measuring instrument that magnifies the image of a small part and projects it onto a screen for accurate measurement and inspection.

It is widely used in:

- Automotive – checking gears, shafts, cams

- Aerospace – precision engine parts

- Electronics – PCB inspection

- Medical devices – surgical instruments

- Tool and die making – molds and dies

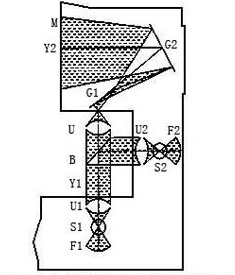

Profile Projector Diagram

A profile projector diagram helps in understanding the instrument’s key components and their functions, showing how light, lenses, and measurement scales work together for precision inspection.

A standard profile projector diagram includes:

- Light source – projects illumination on the specimen

- Worktable/Stage – holds the object

- Lens system (objective + condenser) – magnifies image

- Projection screen – displays enlarged shadow

- Scales & micrometers—used for precise measurement

This arrangement allows measurement of length, angles, radius, and contours.

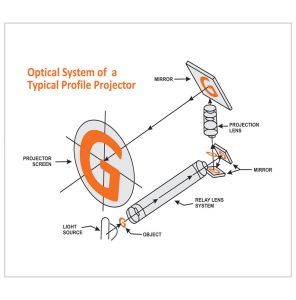

Profile Projector Working Principle

The working principle of a profile projector is simple and based on optical magnification. The process can be explained in clear steps:

1. Illumination of Specimen

Light from the source passes through or reflects from the object placed on the work stage.

2. Image Magnification

The objective lens magnifies the object’s profile to make fine details visible.

3. Projection on Screen

The enlarged image is projected onto a screen for comparison and measurement.

4. Measurement of Dimensions

Operators use micrometers, scales, or digital readout systems to measure lengths, angles, radii, and thread profiles with precision.

👉 This enables highly accurate inspection of shapes, angles, and contours critical for quality assurance.

Profile Projector Uses

Sipcon profile projectors are used to:

- Inspect intricate shapes, angles, and dimensions

- Compare parts with CAD designs

- Ensure high-quality manufacturing standards

- Check gear teeth, threads, cams, tool edges, cutting tools, dies

- Measure radii, angles, and diameters

Additional instruments for precise inspection include:

- Drawing Die Measurement

- Cable Slicer

- Carbon Black and Void Contamination Microscope

- Die Inspection Microscope

Advantages and Disadvantages of Profile Projectors

Advantages

- High Accuracy and Reliability: Provides precise measurements for critical components, ensuring consistent quality.

- Non-Contact Inspection: Measure parts without causing any physical damage, preserving delicate components.

- Capability to Measure Complex Shapes: Ideal for intricate profiles, radii, and angles that require detailed inspection.

- Cost-Effective Alternative to CMMs: Offers precision at a fraction of the cost of coordinate measuring machines.

- Ideal for Quality Control and R&D: Supports inspection, prototyping, and product development in multiple industries.

Disadvantages

- Limited to 2D Measurements: Not suitable for full 3D dimensional analysis without advanced systems.

- Requires Skilled Operation: Accurate results depend on operator expertise and experience.

- Not Suitable for Very Large Parts: Best for small to medium sized components due to stage limitations.

- Needs Regular Calibration: Maintain accuracy through periodic calibration and maintenance.

- Potential for Optical Errors: Misalignment or improper use can lead to measurement inaccuracies.

- 0.001 mm – 0.01 mm

Suitable for industries requiring high precision & tight tolerances.

Profile Projector Least Count

Types of Sipcon Profile Projectors

Precision engineering requires different types of profile projectors to meet diverse measurement and inspection needs. Sipcon profile projectors are widely used across industries due to their reliability and versatility. Here’s a detailed overview of the main types:

1. Vertical Profile Projector

The vertical profile projector has a light source that travels vertically from below the worktable. This design is ideal for flat and thin objects such as gaskets, films, and printed circuit boards (PCB). The vertical configuration allows precise magnification and measurement of 2D profiles without distortion. Its compact design also makes it suitable for electronics and plastics industries where space and accuracy are critical.

2. Horizontal Profile Projector

In a horizontal profile projector, light travels horizontally across the object. This type is best suited for heavy or cylindrical parts, including shafts, gears, and cams. Horizontal projectors are widely used in automotive, aerospace, and mechanical engineering sectors because they can handle larger and bulkier components while maintaining micron-level measurement accuracy.

3. Optical Profile Projector

The optical profile projector is the traditional and most widely used type. It relies solely on optical magnification to project the image of a component onto a screen. Known for its high accuracy and reliability, it is ideal for industries that require precise inspection of gears, tools, dies, and mechanical parts.

4. 2D Profile Projector

A 2D profile projector focuses on measuring two-dimensional shapes, dimensions, and profiles. It is particularly useful for flat components and intricate designs, allowing engineers to compare actual parts with CAD drawings or technical specifications quickly.

5. Video Profile Projector

The video profile projector integrates a digital camera that displays the magnified image directly on a monitor. This makes measurements easier and faster, with software-assisted tools for enhanced precision. Video projectors are ideal for R&D labs and quality control departments looking to reduce human error and improve workflow efficiency.

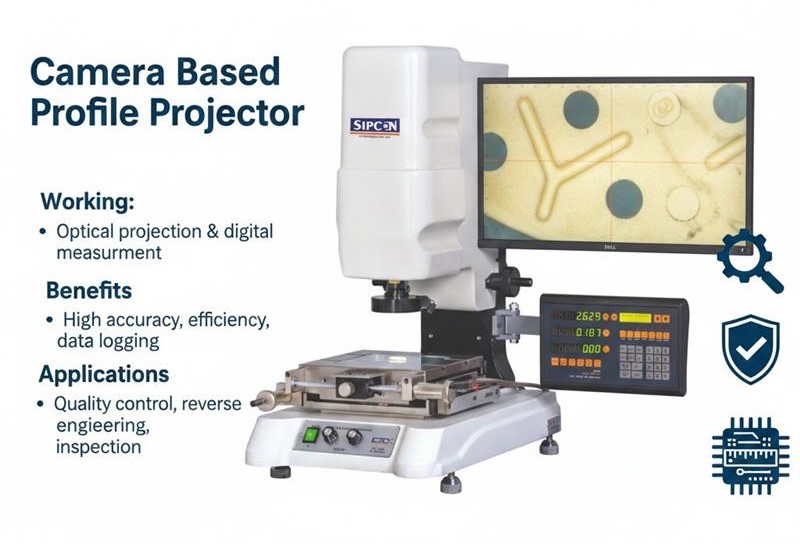

6. Camera-Based Profile Projector

Combining optical and digital technologies the camera based profile projector provides highly accurate measurements with real–time digital analysis. It is suitable for both 2D and 3D inspection, making it a versatile option for complex engineering parts.

7. 3D Profile Projector

The 3D profile projector is designed for measuring three-dimensional shapes and surface profiles of complex components. This type is essential for aerospace, medical, and precision manufacturing industries where surface topology and contour accuracy are critical.

Each type of profile projector serves a specific purpose, helping engineers maintain high-quality standards, achieve micron-level precision, and enhance productivity across various industries.

Profile Projector Pricing

Prices vary based on:

- Type – vertical, horizontal, 2D, 3D, video, camera-based

- Magnification – 10x, 20x, 50x

- Readout – manual or digital

- Advanced features – CNC control, software integration, automation

Sipcon profile projectors are known for:

- High-quality optics

- Robust construction

- Reliable performance

- Excellent after-sales support in Australia

Profile Projectors: Manufacturers in Australia

Sipcon is a trusted name for:

- High-accuracy optics (least count up to 0.001 mm)

- Vertical & horizontal models

- Digital readout & software integration

- Robust build for heavy-duty use

- Strong after-sales service & calibration

Ideal for manufacturers aiming for ISO certification and global quality standards.

FAQs

Q1. Difference between vertical and horizontal projectors?

Vertical: flat/thin objects. Horizontal: large, heavy, or cylindrical parts.

Q2. How to Calibrate a Profile Projector

- Clean stage & lenses

- Place standard calibration scale on stage

- Focus & align with projector screen

- Compare displayed values with actual

- Adjust micrometers or digital readout

- Record calibration results

Recommended: Every 6 months.

Q3. How to Check Radius in a Profile Projector

- Place object on stage

- Focus radius on screen

- Align with radius template or digital overlay

- Measure & compare with design specifications

Q4. How to Use a Profile Projector

- Place part on stage

- Select magnification (10x, 20x, 50x)

- Focus image using knobs

- Align part edges with reference scales

- Measure dimensions, angles, radii

- Record results for QA

Powering Australia’s precision engineering, Sipcon profile projectors are trusted for their micron-level accuracy, reliability, and efficiency. They are ideal for automotive, aerospace, electronics, medical, and tool-making industries.

Q5. What is a 2D profile projector and when should it be used?

A 2D profile projector measures two-dimensional shapes and profiles. It’s best for flat components and intricate designs where CAD comparison is needed.

Q6. How does a 3D profile projector differ from a 2D projector?

A 3D profile projector captures the full surface geometry and contours of a component, ideal for complex shapes and aerospace, medical, or precision engineering applications.

Q7. What is an optical profile projector and its advantages?

An optical profile projector uses traditional optical magnification to project a part’s image onto a screen. Advantages include high accuracy, non-contact measurement, and suitability for gears, tools, and dies.

Q8. How to choose between 2D, 3D, and optical profile projectors?

Consider part complexity, required precision, and industry application:

- 2D for flat and simple parts

- 3D for complex geometries and surface profiling

- Optical for traditional precision measurement and cost-effective inspection

Get the Best Profile Projector Price Today!

Looking for a high-precision profile projector at the best price in Australia? Sipcon offers affordable, reliable, and accurate solutions tailored for your industry needs.

👉 Call us now at +61 426 368 868 or email export@sipconinstrument.com to get a free quotation and expert guidance on choosing the right model.