How Image Based Measuring Machines Are Transforming Precision Manufacturing in the USA

Precision manufacturing in the United States is undergoing rapid evolution. From aerospace and automotive to electronics and medical device manufacturers are under constant pressure to deliver higher accuracy, faster inspection and consistent quality. all while controlling costs. Traditional contact based dimension measurement tools are no longer sufficient for these demands.

This is where Image Based Measuring Machines, also known as Image Dimension Measurement System are transforming how American manufacturers inspect, measure and validate components.

What Is an Image Based Measuring Machine?

An Image Based Measuring Machine is a non-contact dimension measurement system that uses high resolution industrial cameras, precision optics and intelligent image-processing software to measure the size, shape and geometry of components.

Unlike conventional dimension measurement instruments such as vernier calipers, micrometers or gauges image based systems:

- Capture a digital image of the component

- Detect edges automatically

- Convert visual data into accurate dimensional values within seconds

This technology eliminates human error, improves repeatability and enables fast inspection on the production floor.

How Image Dimension Measurement Systems Work

The working principle of an Image dimension maesurement system is simple yet powerful:

- Image Acquisition

A high resolution industrial camera captures the image of the part under controlled LED illumination.

- Edge Detection and Image Processing

Advanced algorithms detect edges, contours and features using pattern recognition and auto edge detection.

- Dimension Measurement

Software calculates critical dimensions such as length , width , diameter, thickness, angles, pitch, concentricity and ovality.

- Instant Reporting

Results are displayed instantly with pass/fail indication, SPC data, and customizable Excel or PDF reports.

This entire process often takes less than 1–5 seconds, making it ideal for high-volume manufacturing environments in the USA.

Why US Manufacturers Are Shifting to Image-Based Dimension Measurement

1. Non-Contact Measurement for Delicate Parts

Industries such as electronics, medical devices, rubber and cable manufacturing deal with soft or deformable components. Image based measurement eliminates physical contact , ensuring accurate results without damaging parts.

2. Speed and Productivity

Modern image dimension measuring machines can measure thousands of points in one click, dramatically reducing inspection time compared to manual tools or even traditional CMM machines.

3. Operator-Independent Accuracy

With 360° auto-alignment and automated measurement, results are no longer dependent on operator skill—an important advantage for US factories facing skilled labor shortages.

4. Compliance with Global Standards

Image-based systems support measurements aligned with ISO, ASTM, EN, and industry-specific standards, making them ideal for export-driven US manufacturers.

Applications of Image Based Measuring Machines in the USA

Image based dimension measurement tools are widely used across American industries:

- Automotive manufacturing – Seals, springs, cables or machined parts

- Aerospace – Precision CNC components, GD&T inspection

- Electronics – Micro components, connectors, PCB features

- Medical devices – Non-contact inspection of delicate parts

- Cable & wire industry – Insulation thickness, ovality, diameter

Sipcon Image Based Measurement Solutions for US Manufacturing

Sipcon Technologies offers a specialized range of Image Based Measurement Systems, each designed for specific industrial applications.

Cable Genie – Precision Cable Measurement Made Easy

Cable Genie is designed for manufacturers who must maintain strict control over cable insulation thickness, diameter, and ovality.

Why it matters in the USA:

US cable manufacturers must balance material cost optimization with compliance to statutory standards. Even minor deviations can cause failures or rejections.

Key benefits:

- Measures cable diameters from 0.5 mm to 144 mm

- 10,000 measurement points for maximum accuracy

- Measurement time less than 1 second

- Supports XLPE cable and color percentage measurement

- Operator-independent with 360° compensation

- Customizable reports as per EN and IS standards

Cable Genie enables fast, repeatable, and reliable dimension measurement directly on the shop floor or in quality labs.

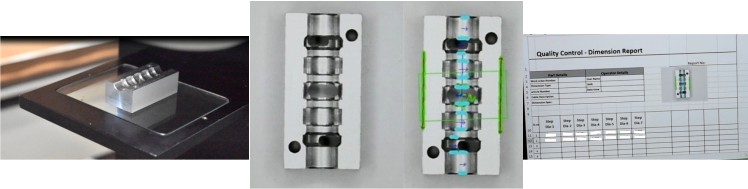

Part Genie – One-Click Measurement for Precision Components

Part Genie is a powerful image dimension measuring machine for 2D geometry inspection of machined and CNC components.

Ideal for US industries like:

- Aerospace

- Automotive

- Precision engineering

- Electronics and fuel injection systems

Key capabilities:

- Measures up to 240 mm parts in one click

- Accuracy up to ±3 microns

- GD&T features: concentricity, parallelism, straightness and ovality

- Batch inspection with color-coded pass/fail reports

- DXF overlay for CAD comparison

Part Genie replaces multiple dimension measurement tools with one fast, intelligent optical system.

Rubber Seal Genie – Accurate Measurement of Soft & Flexible Seals

Measuring rubber seals and weatherstrips is challenging due to deformation and handling issues. Rubber Seal Genie solves this with a dedicated image-based solution.

Applications:

- Automotive door , window , bonnet and sunroof seals

- Truck, tractor and passenger vehicle rubber components

Key advantages:

- Measurement in under 5 seconds

- No alignment or physical drawing required

- DXF overlay for deviation analysis

- High image clarity with telecentric lighting

- Measures multiple seals in a single field of view

For US automotive suppliers, Rubber Seal Genie ensures consistent quality with minimal inspection effort.

Spring Genie – Advanced Optical Measurement for Springs

Spring Genie is built for fast and accurate inspection of springs, measuring 35+ parameters in one click.

Why US manufacturers prefer it:

- Measures springs from 0.5 mm to 140 mm diameter

- Accuracy up to 3 microns

- Zero maintenance (no moving parts)

- Measurement time around 3 seconds

- Horizontal, vertical, or dual configurations available

Spring Genie is ideal for automotive, industrial, and precision spring manufacturers seeking speed without sacrificing accuracy.

Image Dimension Measurement System Price: What to Expect

Many manufacturers ask:

“What is the price of an image dimension measurement system?”

The cost depends on:

- Measurement range and field of view

- Camera resolution and optics

- Software features and automation level

- Industry-specific requirements

Instead of a fixed price, US manufacturers benefit more from solution-based configuration, ensuring the system matches production needs and ROI expectations.

The Future of Dimension Measurement in the USA

As American manufacturing moves toward Industry 4.0, smart factories, and zero-defect production, image-based dimension measurement tools will continue to replace manual inspection methods.

Their advantages speed, accuracy, non-contact inspection and digital reporting make them essential for modern quality control.

Call to Action

Looking for the Right Image Based Measuring Machine for Your Application?

Whether you manufacture cables, precision parts, rubber seals or springs, Sipcon Instrument offers custom configured Image dimension maesurement systems designed for real production environments.

👉 Get expert guidance, application evaluation and a tailored quotation today.

👉 Contact Sipcon Technologies to transform your quality inspection process.

✉️: us@sipconinstrument.com

📲: +1 (262) 391-4785

📍: 260 North Beaumont Ave Brookfield Wisconsin 53005 USA

Frequently Asked Questions

Q1: What is dimension measurement in manufacturing?

Dimension measurement is the process of measuring physical features such as length, width, diameter, thickness, angles and tolerances to ensure a part meets design and quality specifications.

Q2: What image dimension measurement system is used for?

Image dimension maesurement systems are used for non contact and high accuracy inspection of parts in industries like automotive, aerospace, electronics, medical devices and cable manufacturing.

Q3: How accurate are image based measuring machines?

Modern image based measuring machines can achieve accuracy up to ±3 microns depending on the system configuration and application.

Q4:Are image based measurement systems better than manual tools?

Yes. Image based systems offer faster inspection, higher repeatability, operator independent results and digital reporting, making them superior to manual dimension measurement tools for modern manufacturing.

Q5: How much does an image dimension measuring machine cost in the USA?

The price varies based on application measurement range and features. It is best to request a custom quotation based on your production requirements.

Q6: Which industries benefit most from image based measurement systems?

Automotive, aerospace, electronic, medical device, rubber, spring, cable and precision engineering industries benefit the most from Image dimension maesurement system.

Conclusion

Image Based Measuring Machines are no longer optional—they are essential.

For US manufacturers aiming to stay competitive globally adopting an Image Dimension Measurement System means:

- Higher productivity

- Consistent quality

- Reduced scrap and rework

- Faster time to market

With advanced solutions like Cable Genie, Part Genie, Rubber Seal Genie, and Spring Genie, Sipcon Instrument delivers precision measurement systems designed for real world manufacturing challenges.