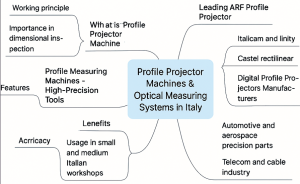

Profile Projector Machines & Optical Measuring Systems in Italy

Within the field of precision engineering in Italy (notably in automotive, aerospace, plastic processing, etc.), there is no room for guessing; even the most minor shift is capable of result in an immeasurably expensive mistake. That is where profile projector machines, along with their innovative dimensioning solutions systems, come in. Using profile projectors that are optical-based and digital, they can give our Italian manufacturers confidence that you will get every part to the detailed specifications necessary to improve quality, efficiency, and competitiveness in the domestic and European markets.

What is a Profile Projector Machine?

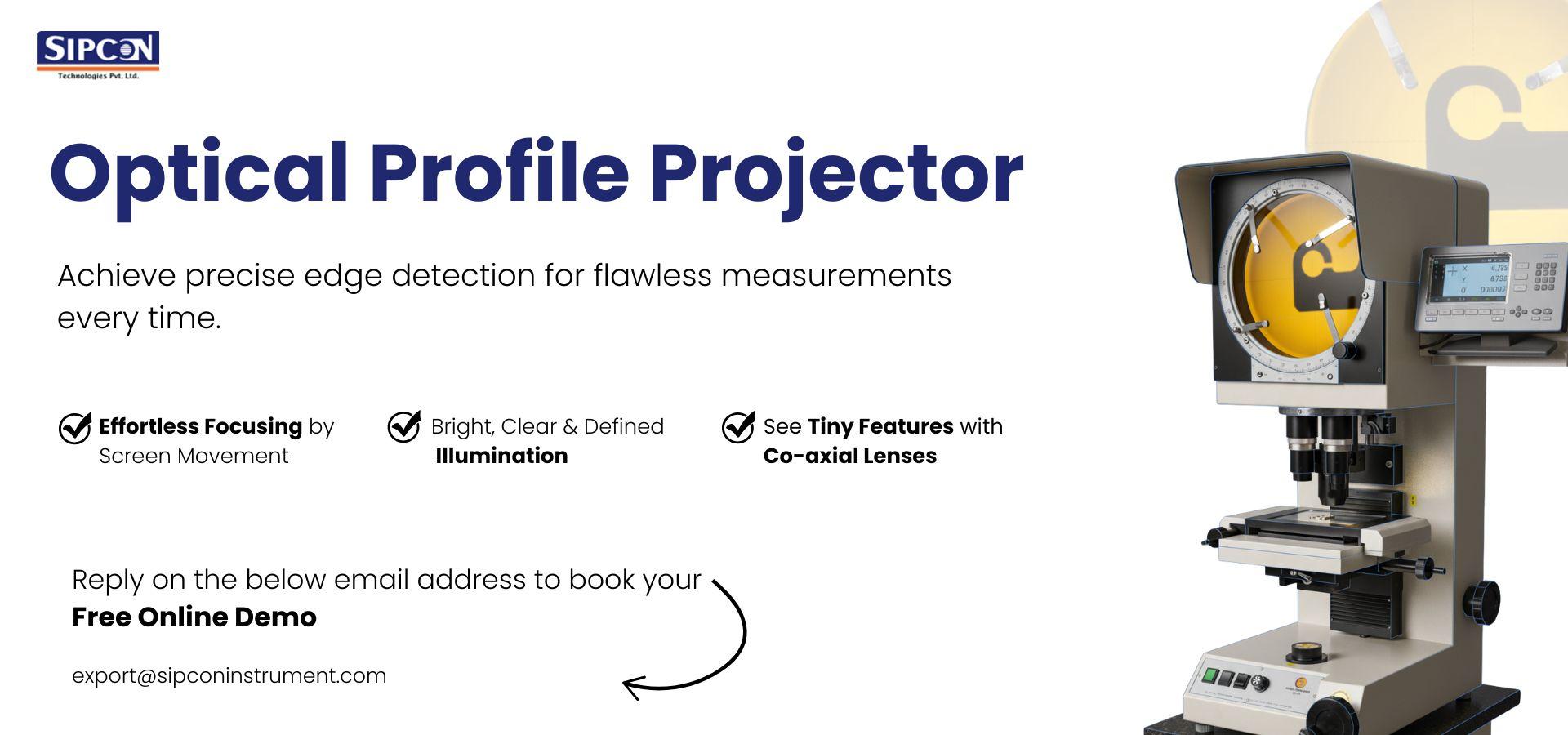

A profile projector machine is developed to magnify the profiles of small parts in order for dimensional inspection. It projects a silhouette of a piece onto a screen (the projector is determined by the model) and the operator is capable of measuring angles with precision, radii, and diameters.

In Italy, companies employ these machines for:

- High-precision dimensional inspection.

- Precision-focused quality in manufacturing the aerospace, automotive, and Manufacturing.

- Compliance with ideas of European and international tolerances

By creating a clear and magnified image, optical projectors help technicians identify variances that could be undetectable to the human eye, assuring consistent quality.

Profile Measuring Machines – High-Precision Tools

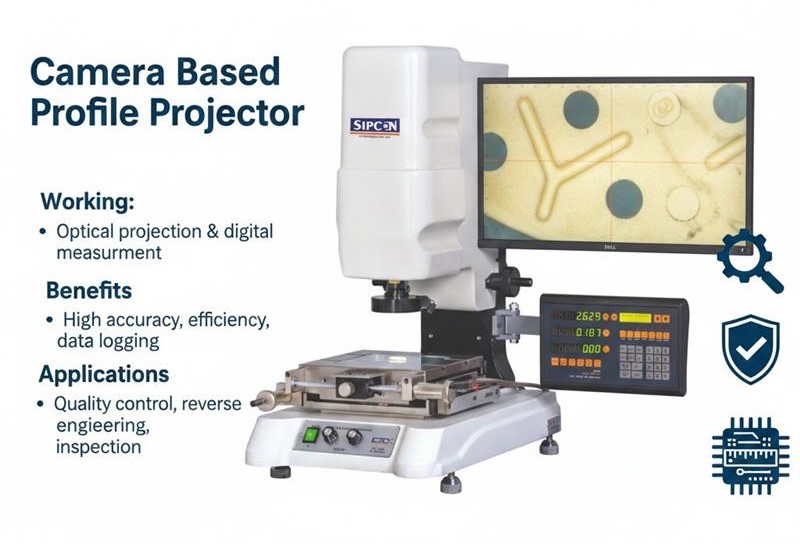

Profile projectors are optical devices. Profile measurement machines are high-precision in that they can ensure measurement accuracy. These machines have digital readouts, an automated sequence and the ability to test without contact, and these features are not found in profile projectors.

In Italy and Italian companies, profile measurement machines are key for:

- The aerospace industry where products are measured in micrometers.

- Tool manufacturers that work with tolerance ranges.

- Molding textured parts with precision, or parts with a pattern.

These aspects of speed, accuracy and reproducibility are very relevant given today’s modern manufacturing systems, which have improved speed greatly.

Optical Profile Projectors – Traditional but Reliable

Optical profile projectors continue to play a role in many Italian workshops because of their simplicity and reliability. Specifically, optical projectors:

- Provide valid measurement of complex parts in 2D

- Continue to be affordable and improve profitability for SMEs

- Are easy for operators to use with little training

Italian SMEs in tooling, manufacture of precision automotive parts and plastic continue to rely on optical projectors for their daily dimensional analysis they are durable and much more consistent.

Digital Profile Projectors – Modern Inspection Technology

The industry has undoubtedly seen a move towards digital profile projectors. They have digital read-outs for accurate measurement are CAD-compatible to directly relay against the CAD model, and have automation features to lessen dependence on human/operator skill. For manufacturers in Italy looking to grow their business, implement Industry 4.0 thought, or rapid increase throughput, the digital profile projectors are a step ahead of the legacy optical systems. They are faster and provide accuracy, but they merge data to create smarter quality control.

Leading Profile Projector Manufacturers in Italy

Italy has a mixture of local and international profile projectors manufacturers of high-quality machines and service, where using an established supplier guarantees:

- Specific industrial requirements are estimated for a personalized solution

- Maintenance and service are performed efficiently

- Access to the latest optical and digital projectors

Manufacturers that are focused on the market in Italy will understand the local industry dynamics and provide post purchase guidance, training, and calibration in compliance with EU-approved standards.

Applications of Profile Projectors in Italy

Profile projectors are prevalent for many different industries within Italy:

- Automotive and aerospace: To inspect gears, shafts, and ultimately parts of precision

- Telecom and cable: To assess the profiles of wires, sizes of connectors, and custom-molded parts

- Plastic melding and packaging proper: To check the consistency of small parts and Molds for packs

From small and medium enterprises to large manufacturing plants, projectors are an important tools to maintain quality and reduce waste.

Future of Profile Measuring Technology in Italy

In Italy, the next generation of profile measuring machines is digital, automated, and integrated into smart manufacturing systems. Some of the key trends include:

- Increase in hybrid optical-digital projectors

- Coupling or incorporating Industry 4.0 and ERP capabilities

- Addition of automation to perform inspections faster and with great precision.

- Ability to collect real-time data

- Predictive methods for quality control

These trends are supporting Italian manufacturers to minimize errors, lower costs and adjust to the changing needs of precision-based industries.

Profile Projector Solutions that you can count on to improve the Italian industry.

Italian manufacturers count on solutions that are accurate, effective, and dependable – all the way up to the newest technologies in profile projectors are accurately measured profile machines.

The best profile projector machine and a profile projector focus on quality with high standards and reducing scraps to improve competitiveness in the domestic and European markets.

Explore the most competitive profile projector price and upgrade your inspection process to match the precision benchmarks of the Italian industry.

👉 Get started today!

Reach us at export@sipconinstrument.com, visit https://www.sipconinstrument.com/italy/, or call +39-3404042357 to start the conversation and take your quality control to the next level.