Video Profile Projector (Italy) is focusing by a moving projection screen ensures sharp, distortion-free profiles every time

Balanced lighting ensures clear , undistorted images for rubber part, cables and complex shapes using Profile Projectors for Rubber parts and cables

Threadless design of Camera Based Profile Projector (Italy) ensures sustained accuracy and smooth operation,allowing frequent checks with ease

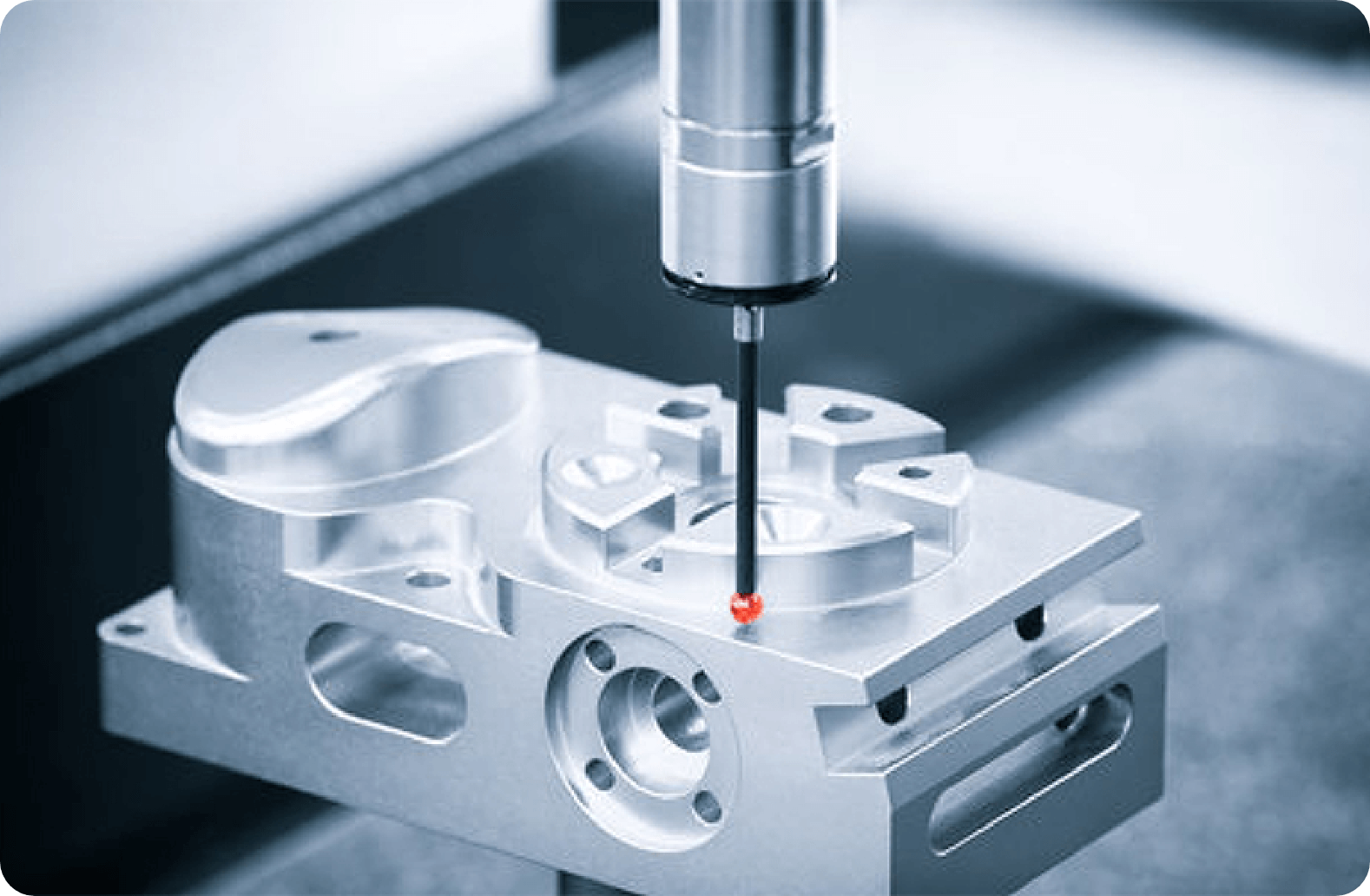

Discover the entire range of our precision measuring tools in one comprehensive guide

Explore advanced 2D, 3D Profile Projectors for every profile

Factor guide by Top Camera Based Profile Projector Manufacturer/Supplier