Our FOV Video Measuring Machine provides faster, more intelligent inspection with all the details captured in a single view eliminating scan work and due to the quick nature of inspection it prevents slowing of production

Across four independent channels of programmable control the system will memorize each light intensity to provide perfectly repeatable illumination for each inspection

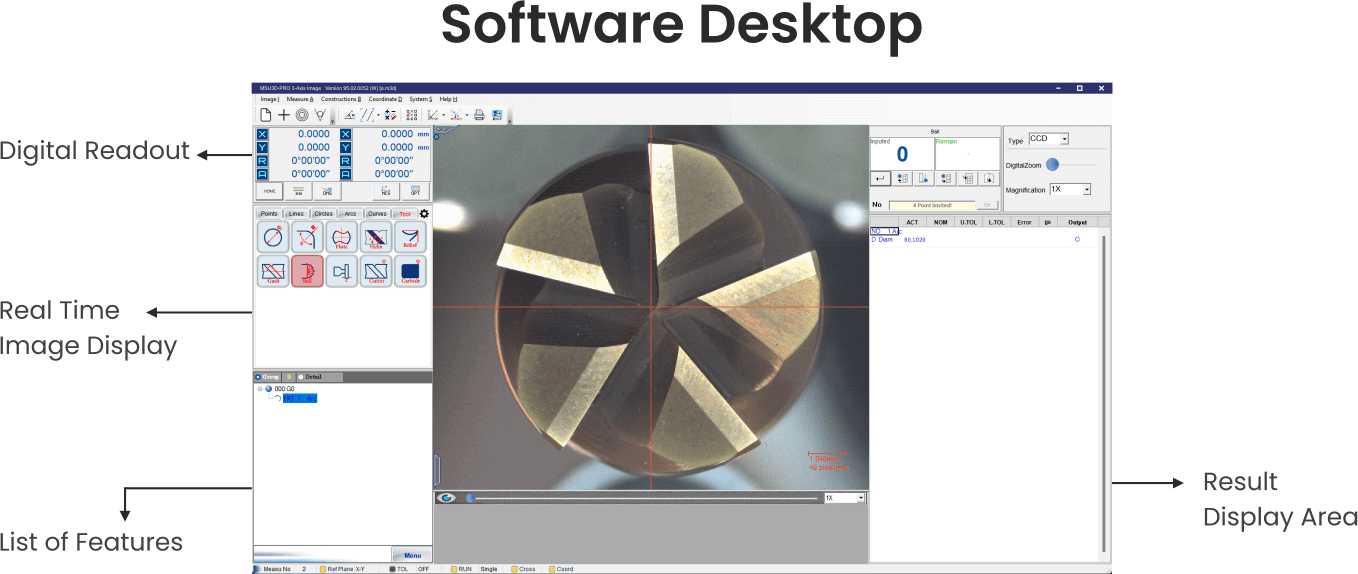

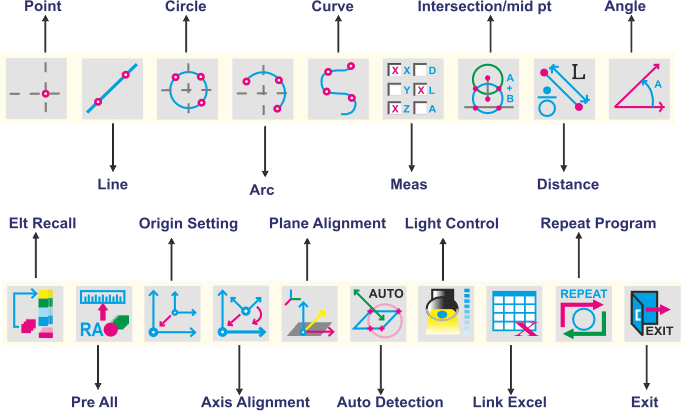

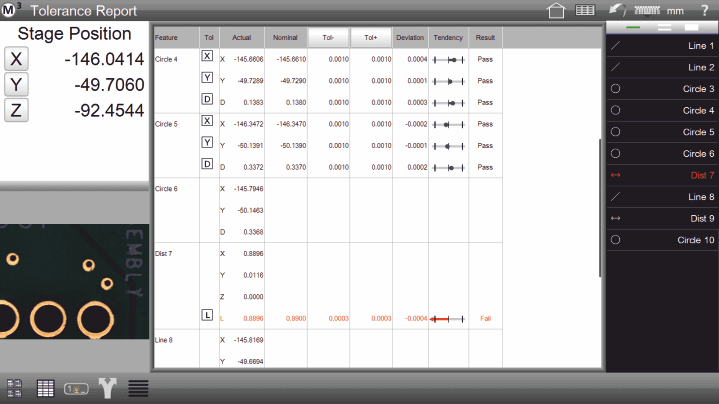

The one click menu bar allows for simple and rapid measurement of geometries, overall calibration, axis alignment, Excel output and programming as a continuous operation

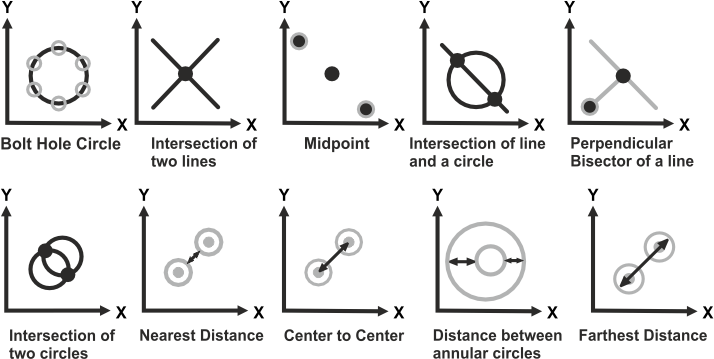

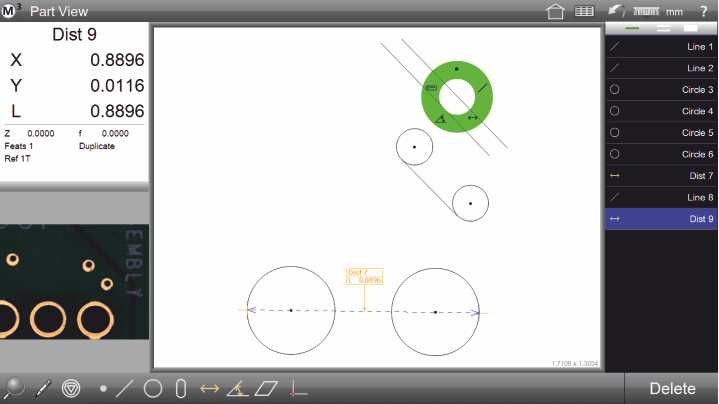

Select two or more features to create intersections or constructions, streamlining the task and minimizing operator workload

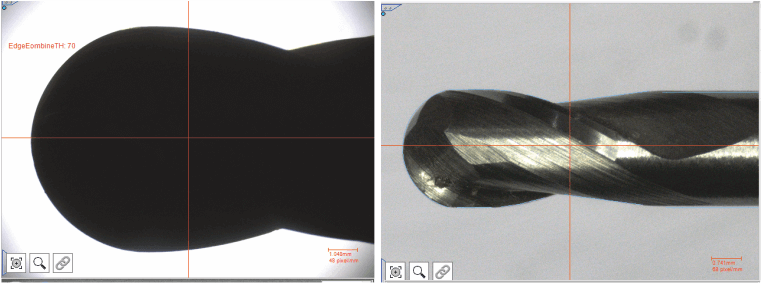

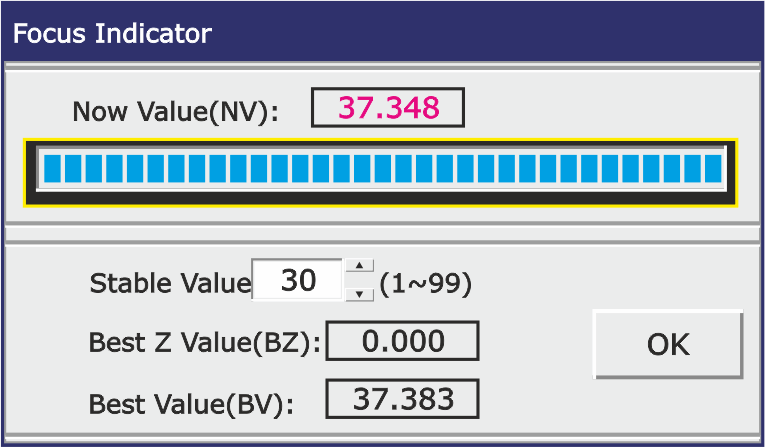

Instantly determines the best focus and Z value, ensuring a clear view and accurate 3D measurement every time

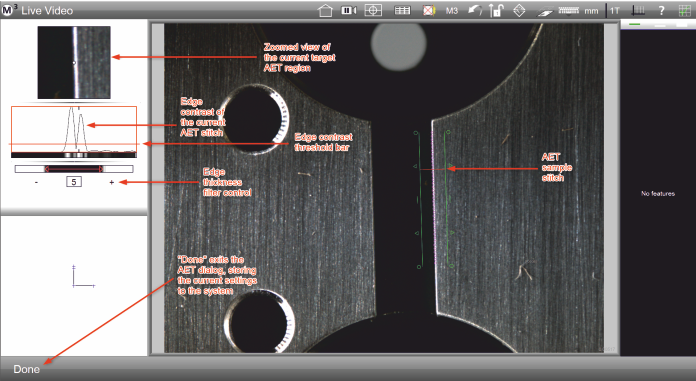

Easily detect edges, even in hard to see lighting or features that are spaced close together or are low contrast

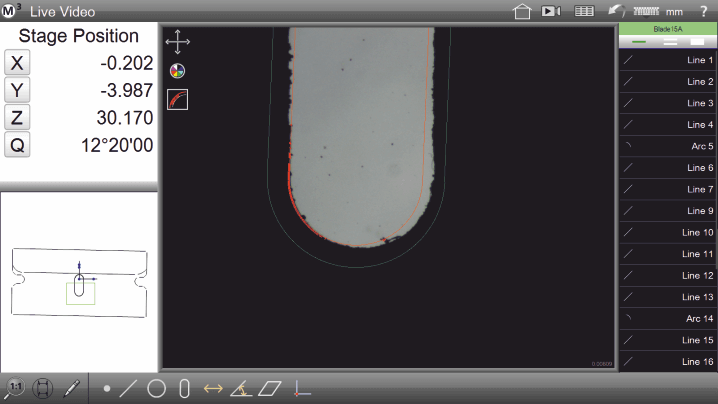

DXF CAD overlays can be imported seamlessly for comparative inspection, and error whiskers showing deviation from the defined tolerance zones can be displayed live

• Flexible Data Formats

• Custom Header Information

• Header & Footer Graphics

• Part View Graphics

• Time and Date Stamps

• Operator & Part Details

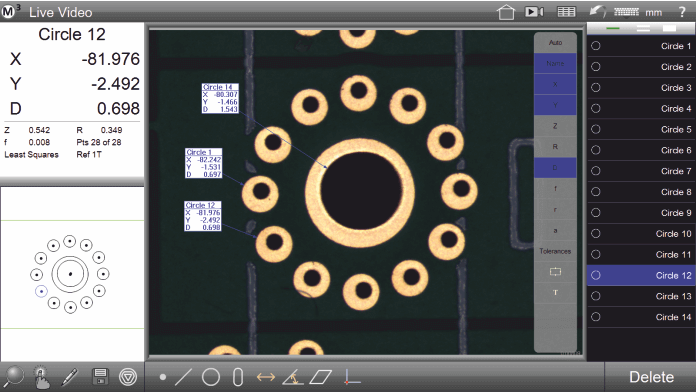

Get to the feature tools right away from the part view "Gesture Menu." Display only the feature data you are interested in directly on your live video image or Part view

Measurements include Size: X/Y/Z positional, Diameter, Radius, Length, Width, Angle (Theta) Form: Straightness, Roundness, Flatness Orientation: Parallelism, Perpendicular, Angularity

Position: True position (LMC/MMC modifiers) Concentricity, Symmetry, Runout.

Explore all our dimensional measurement solutions together in one complete catalogue

Explore the product catalogue from a trusted vision measurement system manufacturer in italy

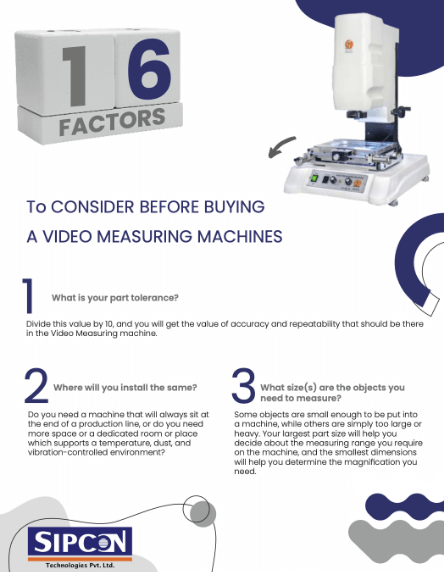

Important factor to be consider before buying vision measurement system according to your measurement needs