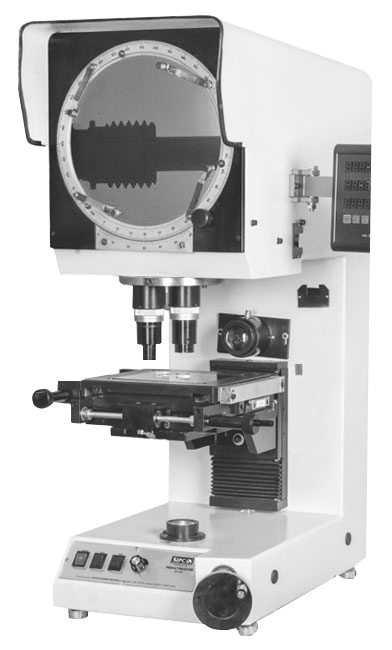

Vertical

Profile Projector

Next-generation profile measurement with speed and accuracy.

- High precision for gears, tools, and rubber parts

- Supports multiple measurement applications

- Non-contact measurement ensures zero part damage

From Focus to Illumination

Built for Perfect Profile Inspection

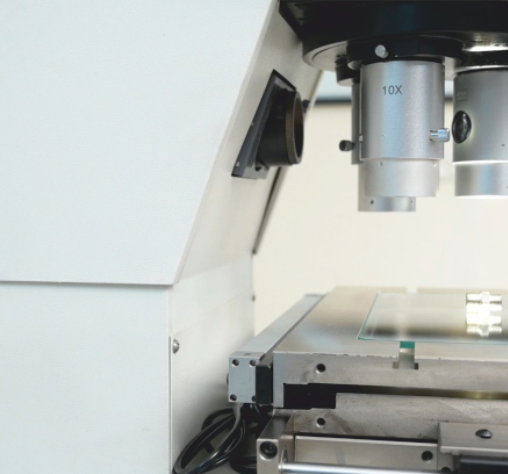

Focusing By Moving Projection Screen

The Vertical Profile Projector is a high-precision profile measuring machine designed for accurate dimensional inspection of small, intricate, and critical components. With its unique focusing by moving projection screen mechanism, it ensures sharp, distortion-free images, making part inspection simple, fast, and highly reliable.

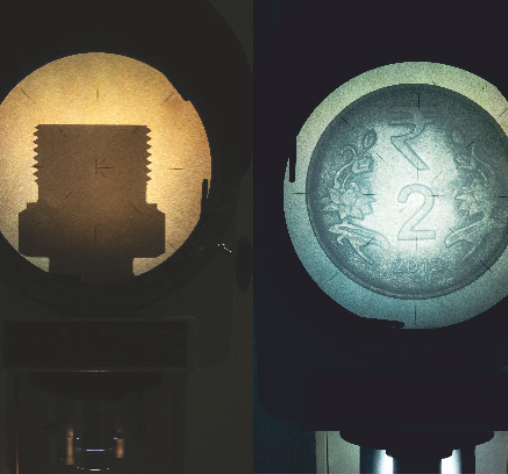

Outstanding Illumination

With precision optical projectors, consistent illumination plays a vital role in achieving repeatable and error-free results. Whether inspecting rubber parts, cables, or complex profiles, the projector guarantees crystal-clear visibility for precise dimensional measurement.

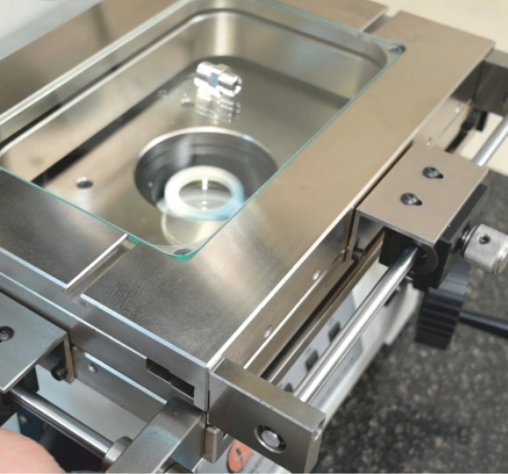

Threadless Workstage

designed for effortless movement and long-term precision. Unlike conventional threaded stages that may wear out or cause jerks during operation, the threadless design ensures frictionfree and smooth travel of the measuring table. This enhances accuracy while inspecting components and makes handling easier for operators.

Technical Data for Camera Based Profile Projector

-

SCREEN

Size: 300/400 mm Construction: Opaque glass screen with 90° cross line fitted with graduated rotary line (0-360°) operated by knob, L.C. 1 min. -

WORKSTAGE SIZE

Std: 250 mm x 250 mm Opt: X-axis upto 550 mm, Y axis upto 350 mm -

MEASURING RANGE

Std: 100 mm x 100 mm Opt: Upto X axis - 400 mm, Y axis - 200 mm -

LIGHT AXIS

Vertical -

FOCUSING

90 mm/100 mm

-

LINEAR MEASUREMENT

Micrometers/Built in glass scale -

OPTICS

Std: 10X Opt: 20X, 50X, 100X Mount: 3 lens turret mount/Screw mount -

ACCURACY

Magnification: #0.05% (Contour/Surface) Measure: 3 + L/100 um -

MEASURING SYSTEM

Micrometer/D.R.O./PC based software -

COOLING SYSTEM

Fan -

ILLUMINATION

Contour: 24V/150W halogen lamp, illumination control with condenser unit provide light as per lens Surface: Twin 24V 150W halogen lamp

-

RESOLUTION

Linear: 0.001/0.0005 mm Angular: 1 sec -

MOTORIZED MOVEMENT

Opt: (x, Y, focusing with speed control) -

OPTIONAL HARDWARE

Profile Charts, Rotary Table, V-block, Centre Holding Device Opto Edge Sensor, Rotary Encoder -

POWER SUPPLY

AC - 110/220V (50/60 Hz) single phase -

STAND

Unique rigid pedestal system facilitates vibration free handling of component

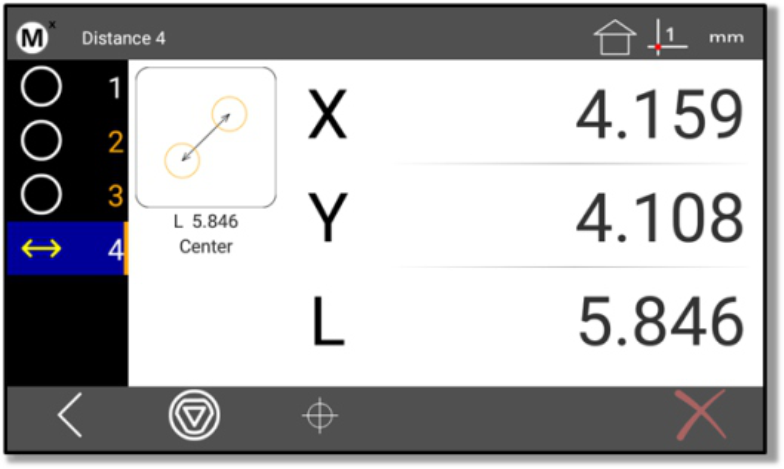

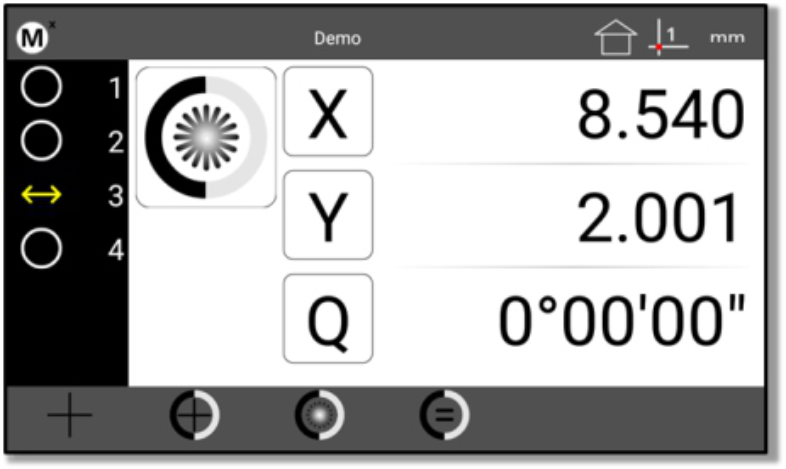

Precision at Your Fingertips with DRO Systems

A Simple & Innovative

Readout Solution

- METLOGIX'S MLX-200

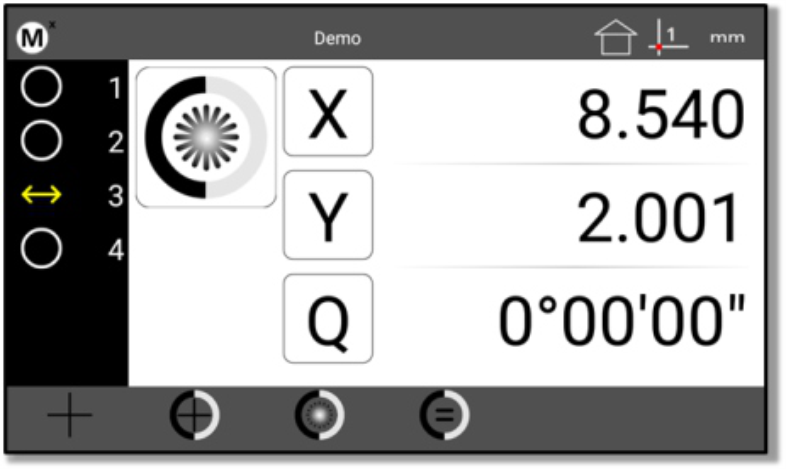

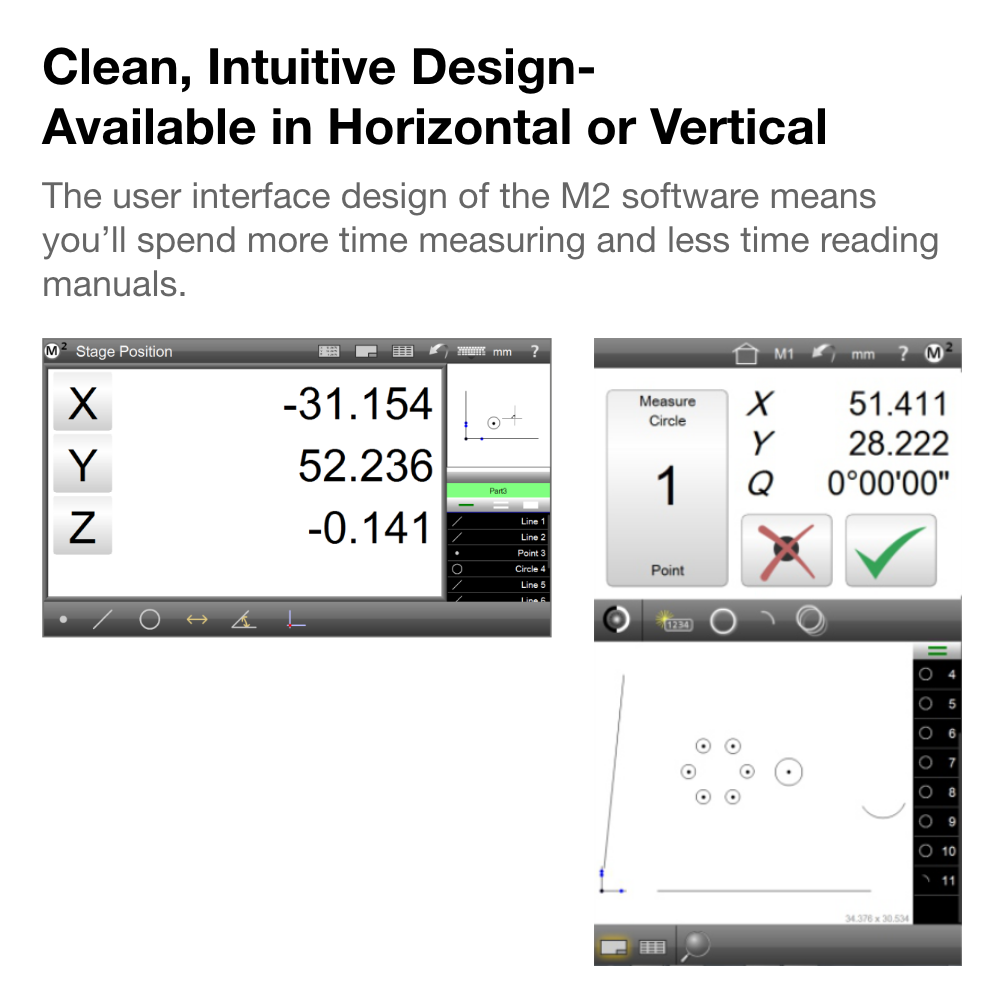

Clean, Intuitive Design

Combining a familiar user experience with current touchscreen conventions, the Mx200 readout can quickly be integrated into your process while being accessible to a wide range of users.

Report Print Export

Choose from one of three report formats; CSV, Standard, or Tolerance. Report contents can include a report title, time and date stamps, and all feature measurement result data.

Export choices include:

Paper Printer(USB, Wifi,Bluetooth), Save to file (USB), RS232 Output

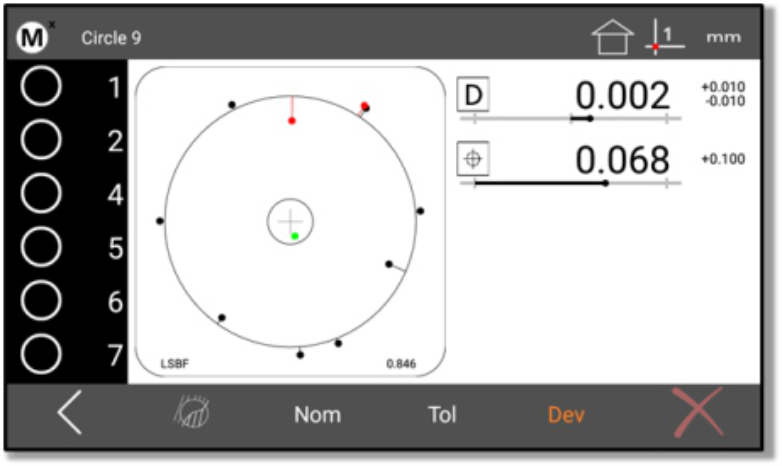

Geometric Tolerancing & Part Programming

Apply popular geometric tolerance controls to measured and constructed features using the industry leading Metlogix tolerance system. Apply nominal and tolerance limits quickly, and view results accurately, in the large and easy to read data views. Record inspection routines for simple playback of measurements, tolerance controls, and data handling and printing steps.

Optical Edge and Crosshair Probes

Available for both Optical Edge and Crosshair only measurement systems the Mx200 probing options are simple and intuitive. The exclusive EdgeLogic™ feature enables gesture driven control of start and end measurement commands, alleviating the need to interact with the DRO directly. Just cross the same edge twice to start and end measurements!

Wireless Data Transfer

Transfer measurement data instantly and wirelessly from your Мx200 readout to a network window computer.

Transfer MxLink data directly to Excel

For more advanced data calculations simply press Export to transfer selected MxLink results to a blank Excel sheet.

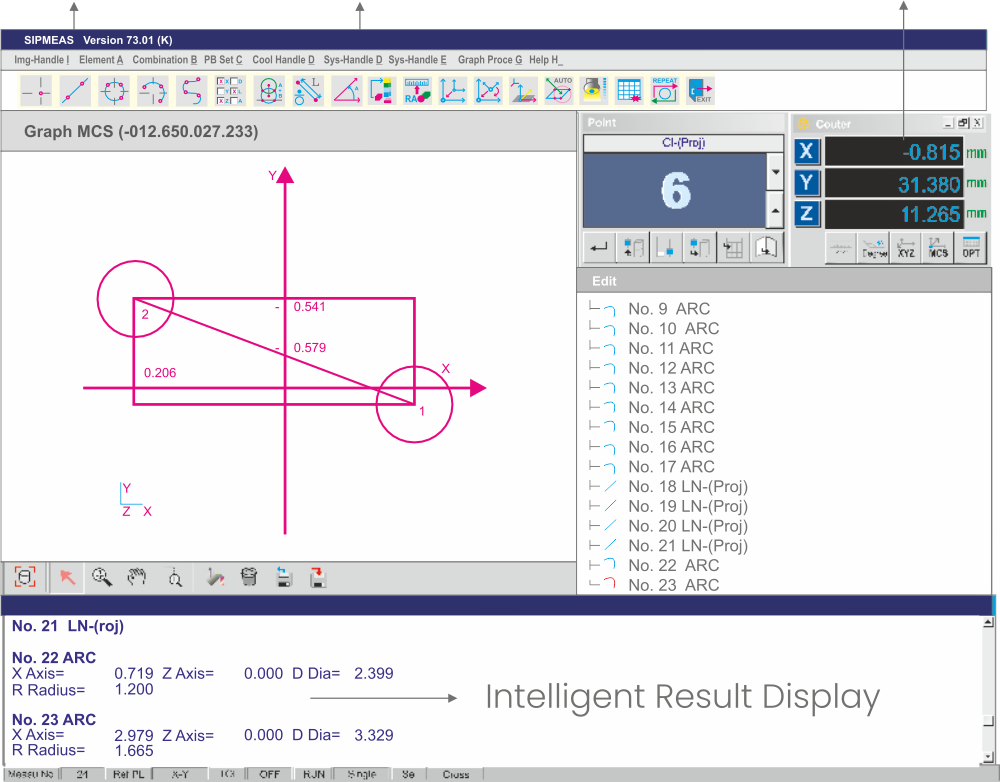

Measuring Software

SIPMEAS

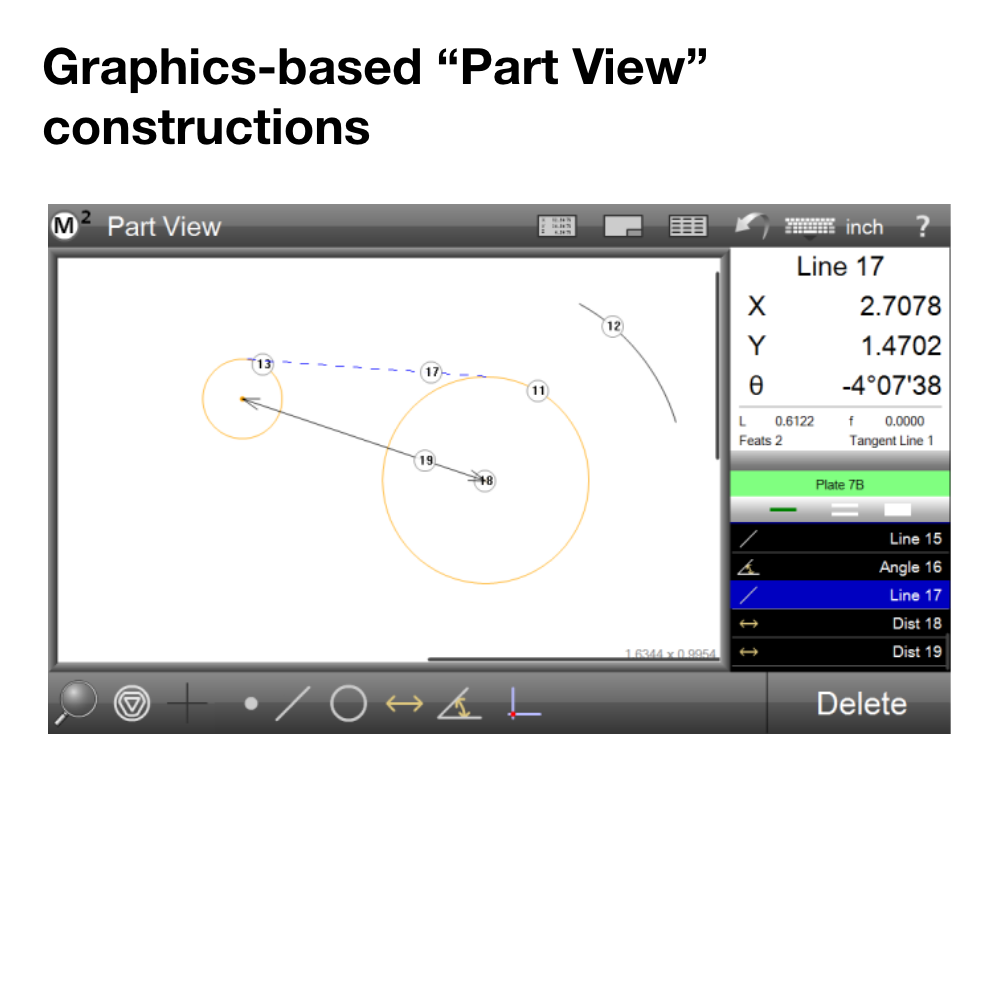

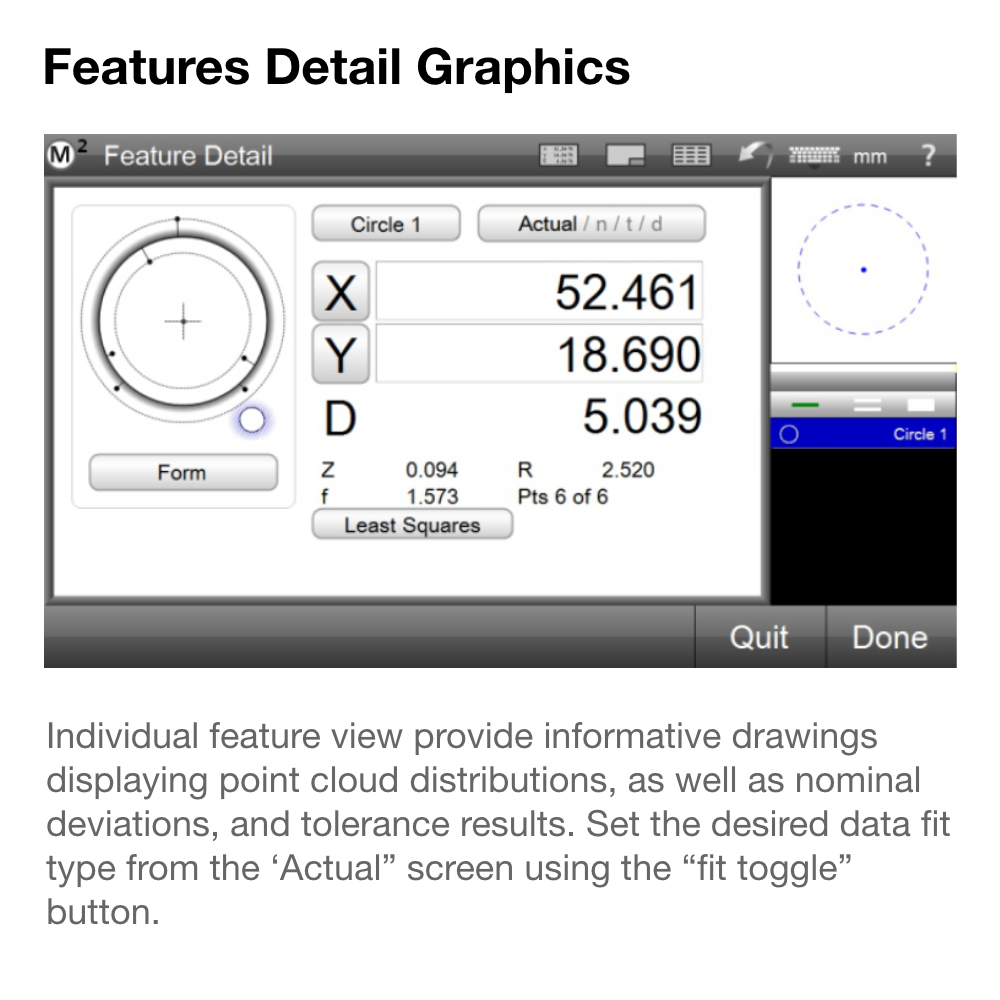

M2 Measuring Software

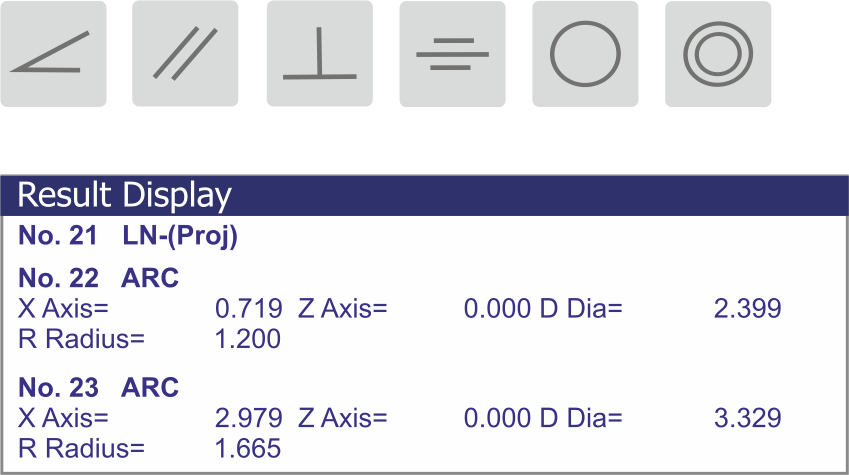

Tolerance Setting & Result Display

Software Desktop

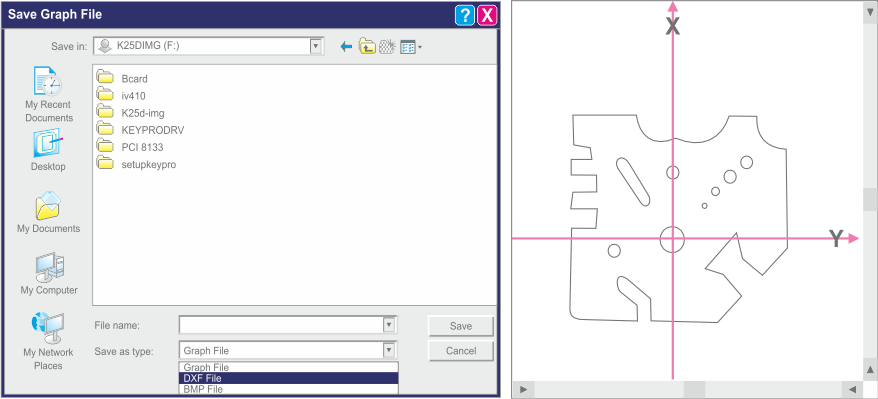

Data Management-Export and Calculations

Directly saving graphs as DXF or IGS files makes it possible to export our measurement to CAD.

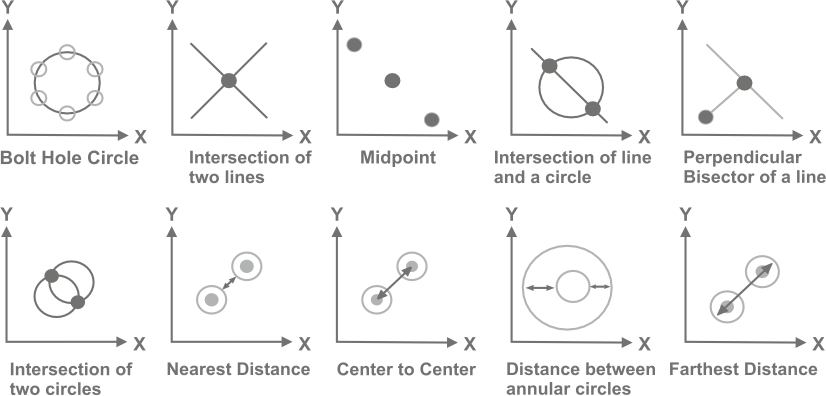

Construction Capabilities

Select two or more features to create intersections or constructions.

M2 Measuring Software

-

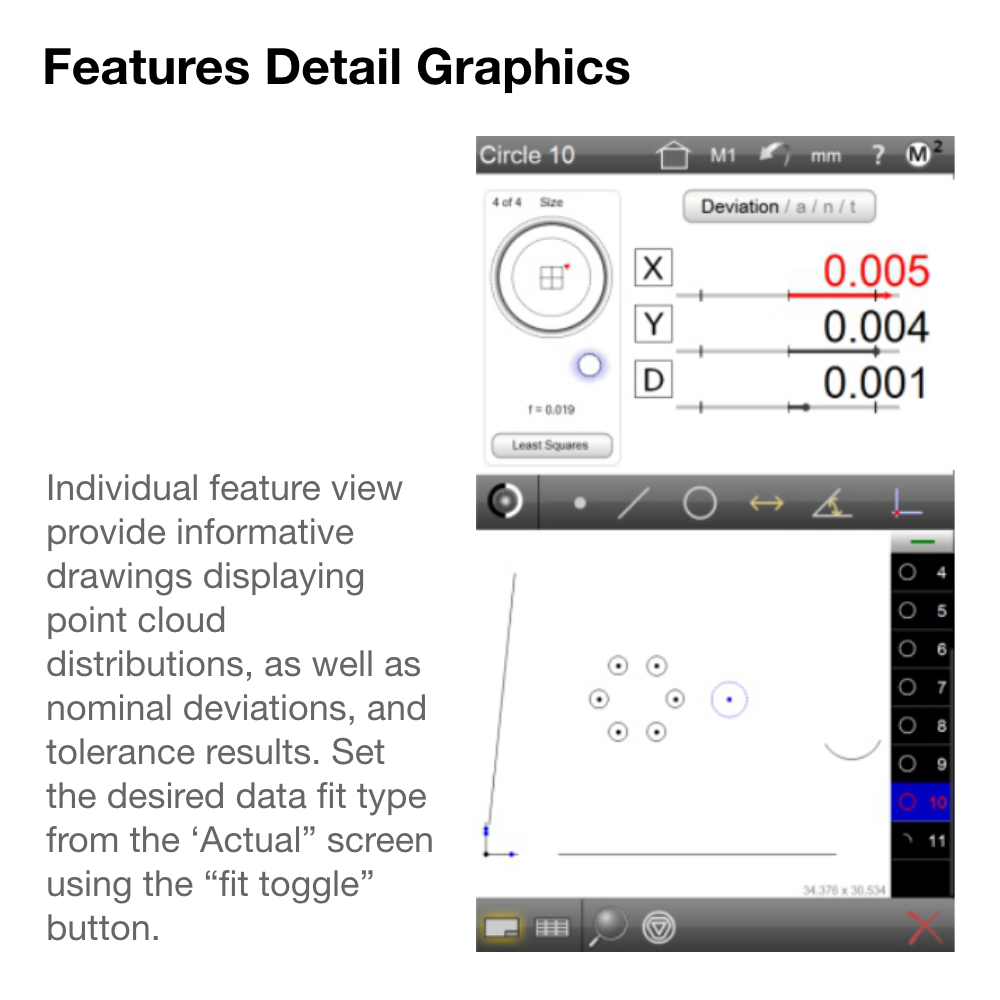

Features

2D- Point, Lines, Circles, Arcs Slots, Rectangles, Blobs Distances, Angles -

Calibrations

LEC, SLEC, NIEC -

Applications

Reverse engineering In line production Quality inspection -

Constructions

2D- Point, Lines, Circles, Arcs Midpoints, Mid Lines, PCD, Distances, Intersection, Bisectors, Offset, Angles -

Tolerances

Size, Form, Orientation, Position, Runout -

Programming

Measure & program -

Measurement Modes

Polar/Cartesian, DMS/ DD, MM/ INCH -

Datumming Features

Skew Alignment Datum (Origin) Points Reference Axis Rotation & Skew -

Exports

PDF, DXF, Excel, CSV, TSV(Tab) Data trasmit to RS 232 port

Contact Us

Let’s Tackle Your Toughest Measurement Problems—Start Here