An advanced version of video measuring system for the Australian industries quality inspection with integrated sensing for unmatched accuracy and efficiency. Designed for meeting measurement needs of rubber and plastic parts from electrical to automotive

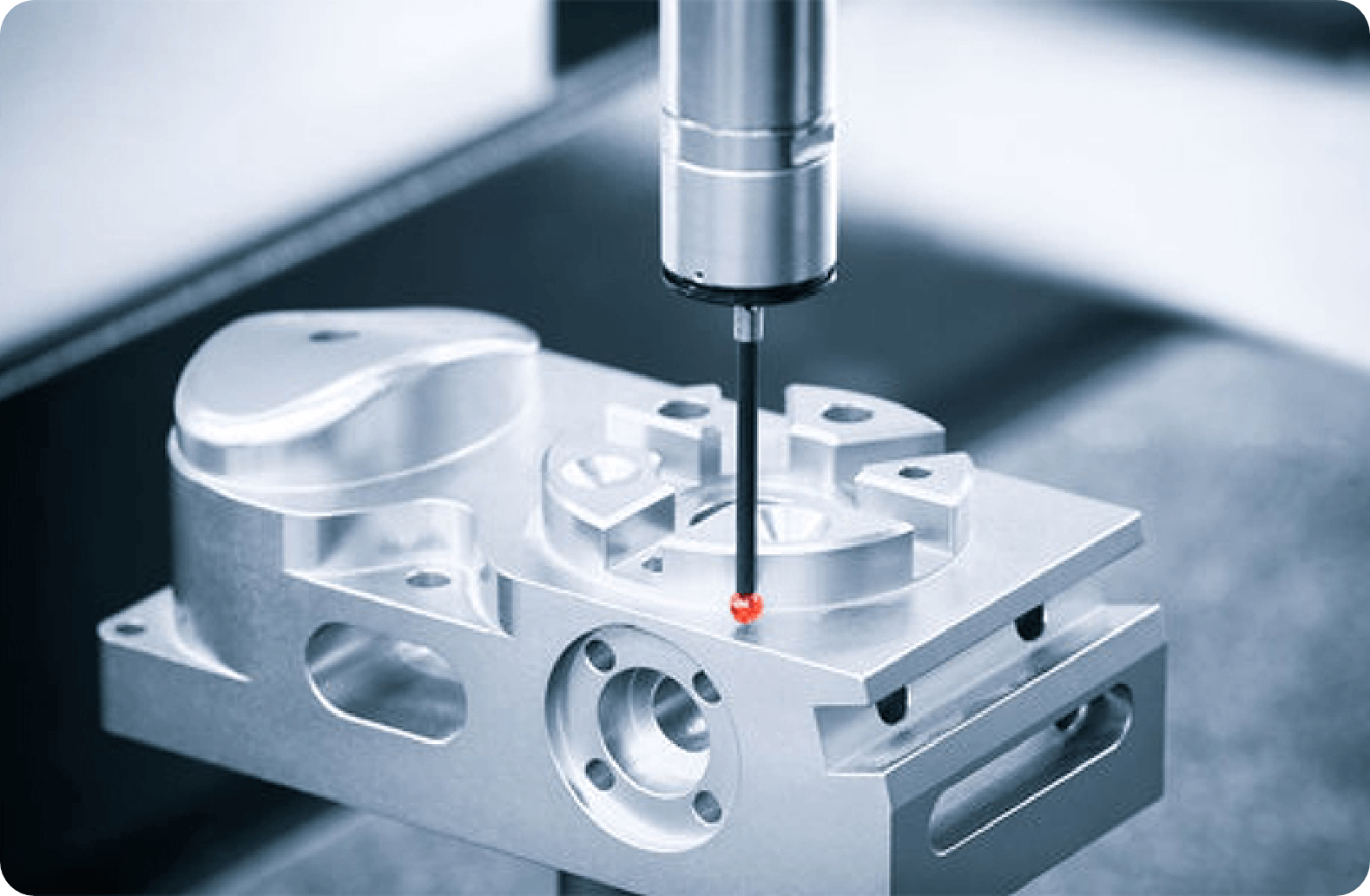

A three in one machine by Top multi sensor cnc machine manufacturers in AU can lead to high accuracy, faster turnaround, and reduced operational costs

Manufacturers in Australia can leverage the rotary indexer, which accurately rotates each part while measuring to allow inspection from multiple angles.

Engineered with a sturdy granite foundation and platform, the system provides optimal rigidity and vibration and temperature stability.

Explore all our dimensional measurement solutions together in one complete catalogue

Download the Combined brochure of Vision measuring system from the leading manufacturer in Australia

Choosing the right system by multi sensor cnc inspection system manufacturer for error-free measurements

Custom Quotes, Detailed Specs, or Pricing.