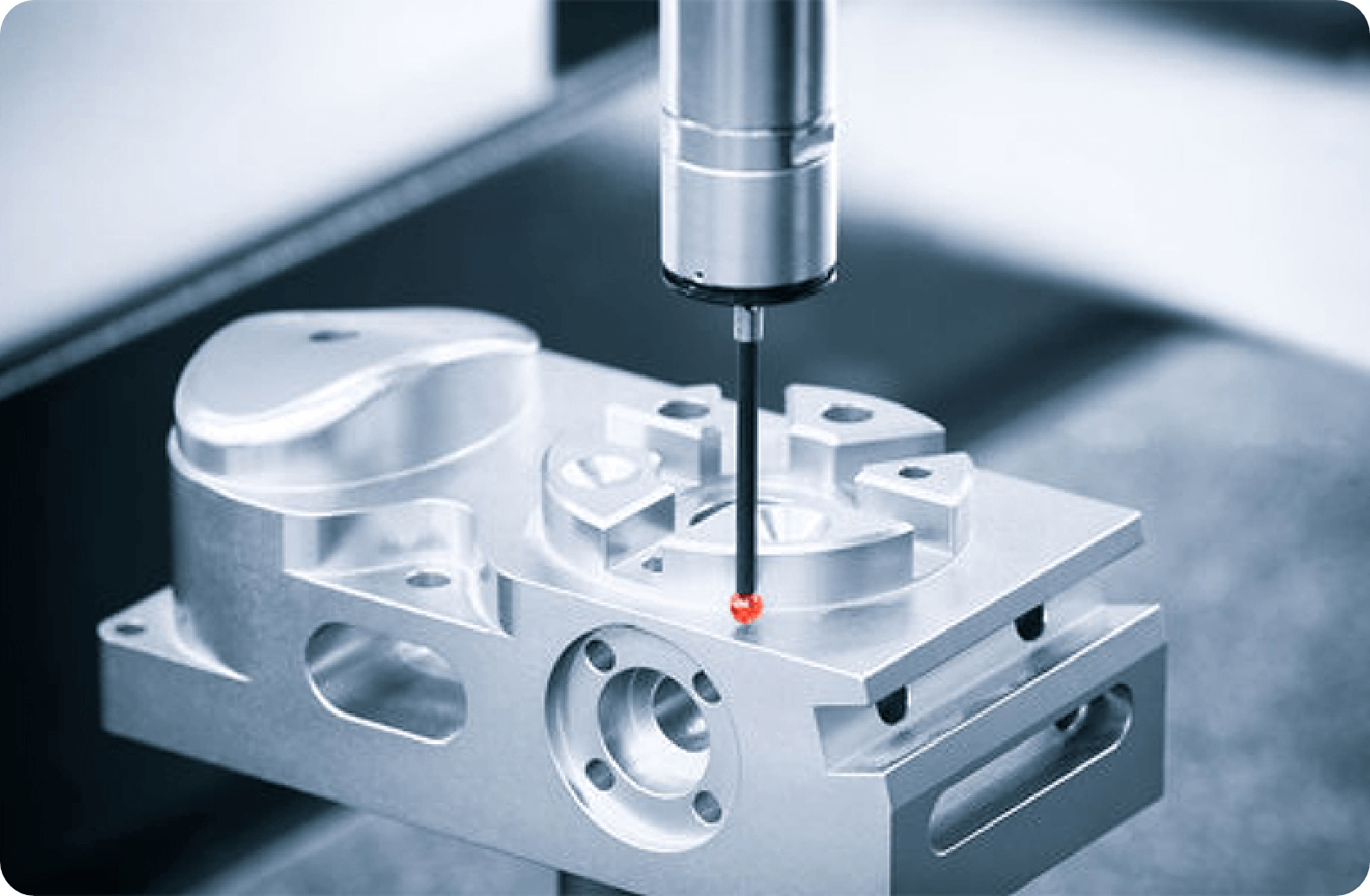

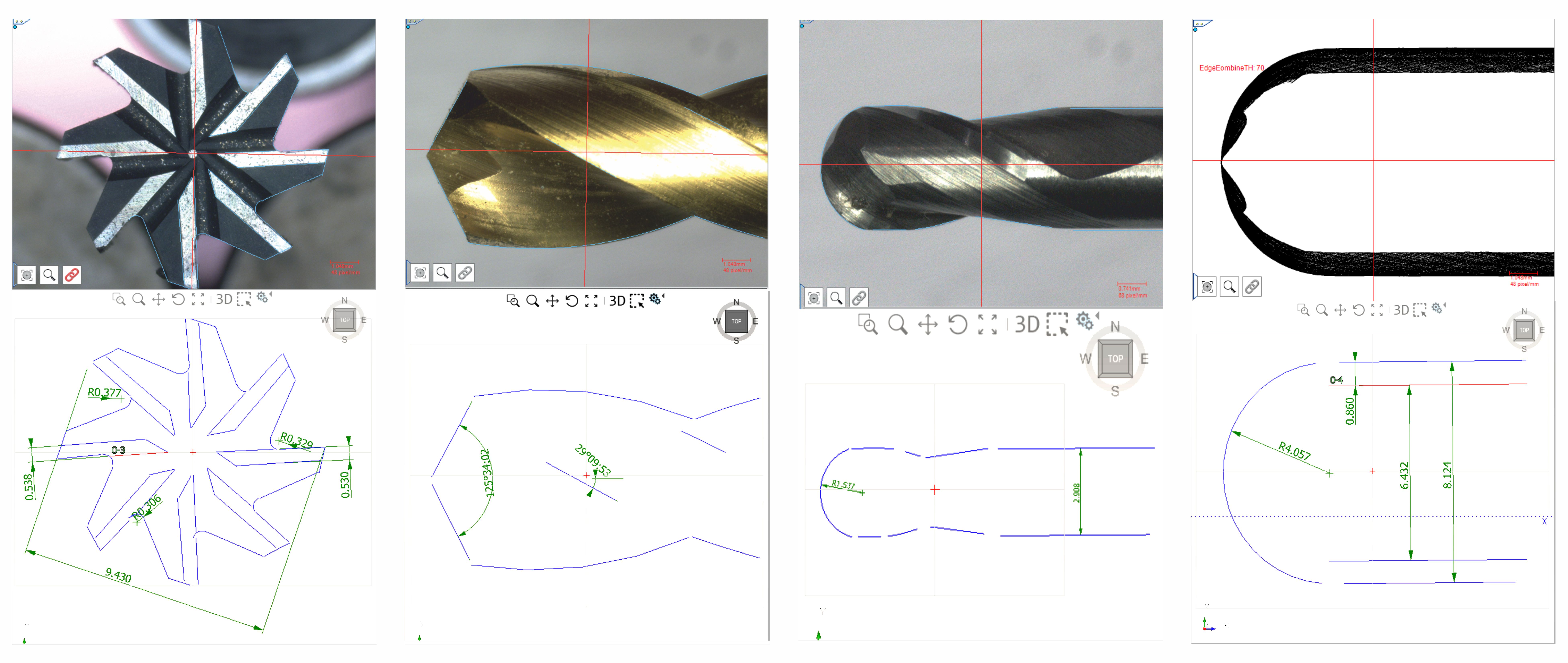

Our sophistication ensures fast and high-precision Cutting tools inspection system measurement ensures accurate axial, radial, and micro-geometry measurement capability. details it ensures reliable results in seconds. Designed for ease of use, it allows every operator to inspect tools efficiently and confidently

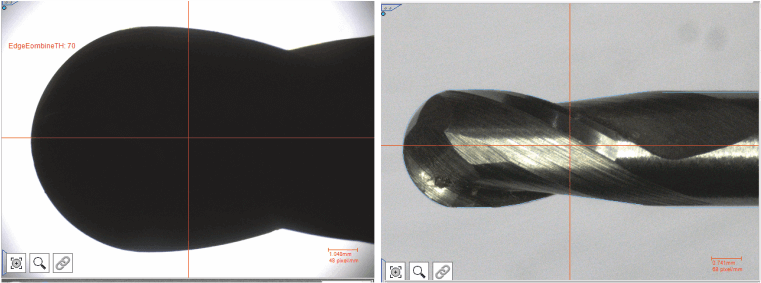

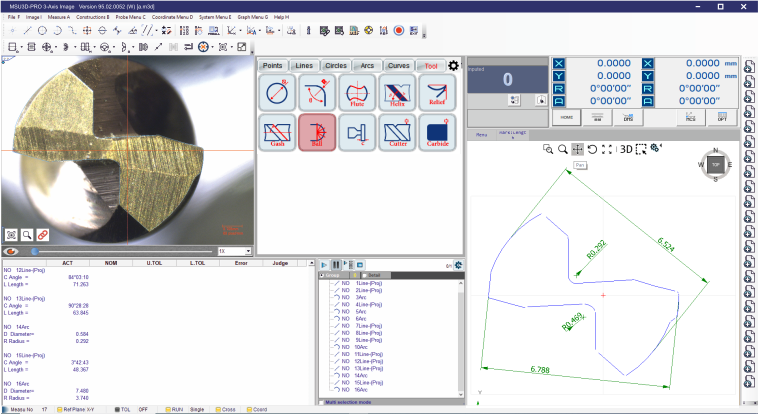

features for ball nose radius and high-point calculations make tool measurement easier, faster, and more accurate

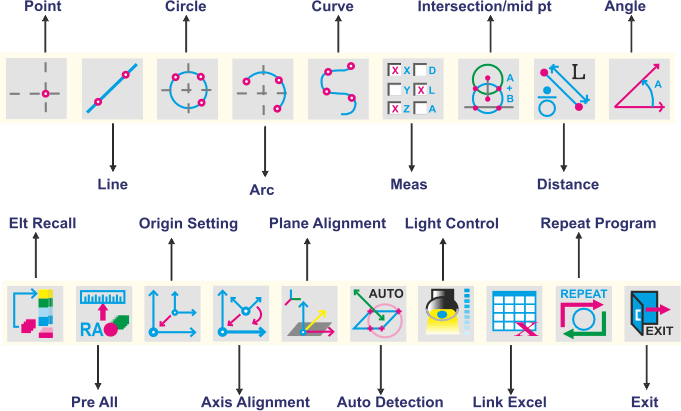

The software supports 4 directional ED Luminating control with programmable settings for each source. Intensity values are stored and automatically recalled, ensuring consistent lighting for every inspection. It also supports a 4-zone LED controller for improved lighting management

A single-click menu for all geometry, origin, and axis alignment made easy alignment, Excel export, and programming – makes operation seamless and efficient

Easily export measurement data in DXF format or IGS files for direct use in CAD and CAM applications

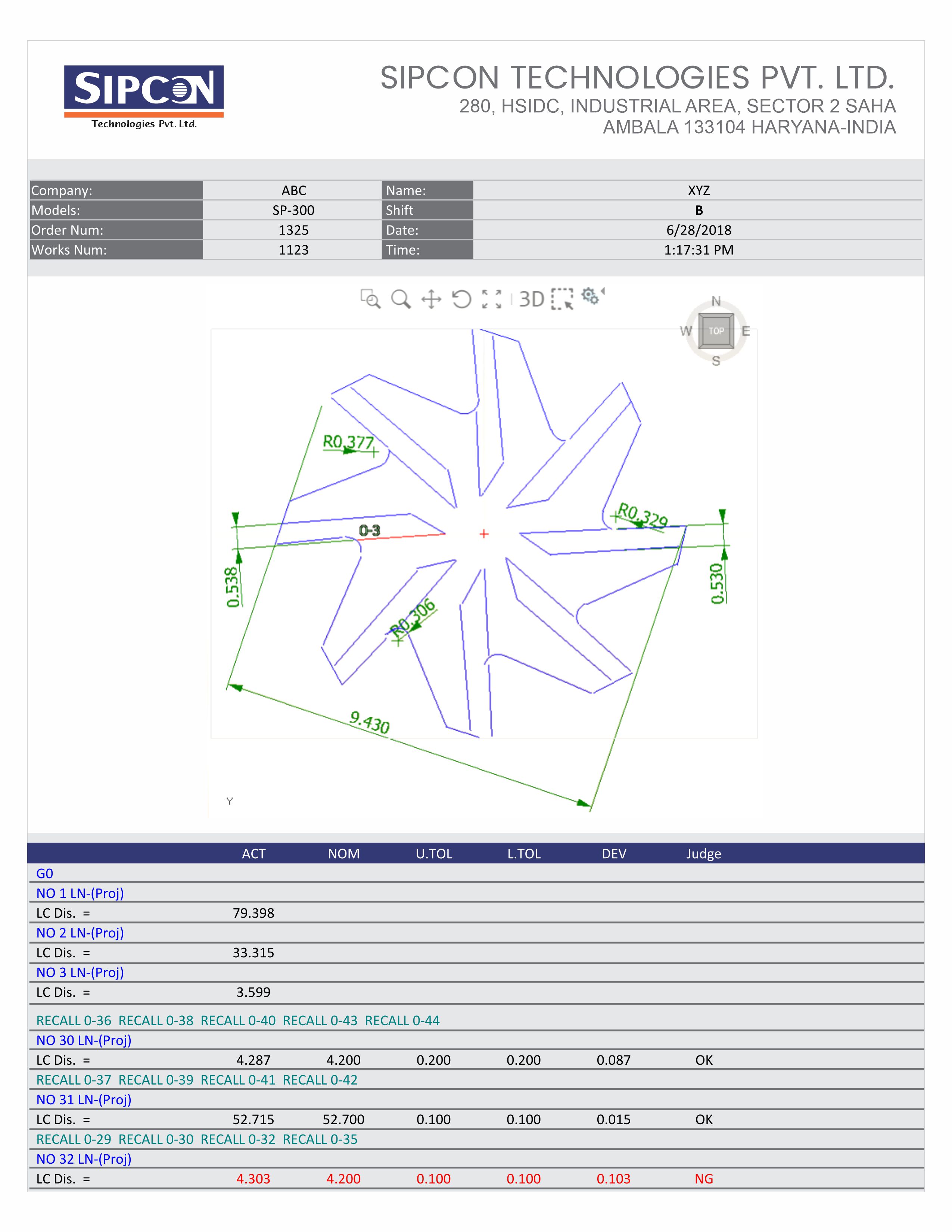

Create personalized reports with color-coded pass/fail indicators, company logos, batch details, operator names, and timestamps. Each report includes the measurement image for clear documentation

Your all-in-one catalogue to explore, compare, and choose the perfect Measurement Machine For Cutting Tool Saudi Arabia

Download

One guide – every answer. Explore, evaluate, and choose the tool inspector best suited for your production needs

Download

Find the right tool inspector with detailed product insights and an easy-to-follow buying guide