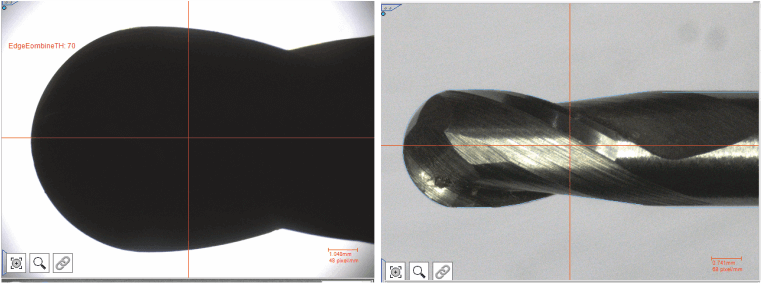

The FOV Video Measuring Machines elevate inspections by through its cutting-edge field of view that requires no scanning while maintaining full precision and reliability It takes just a few images in wide-view to capture and evaluate, with results instantly available; no more waiting or scanning.

Each channel of the 4-channel light controller can be programmed to a specific value, which is stored in the program for consistent reuse while the system is running.

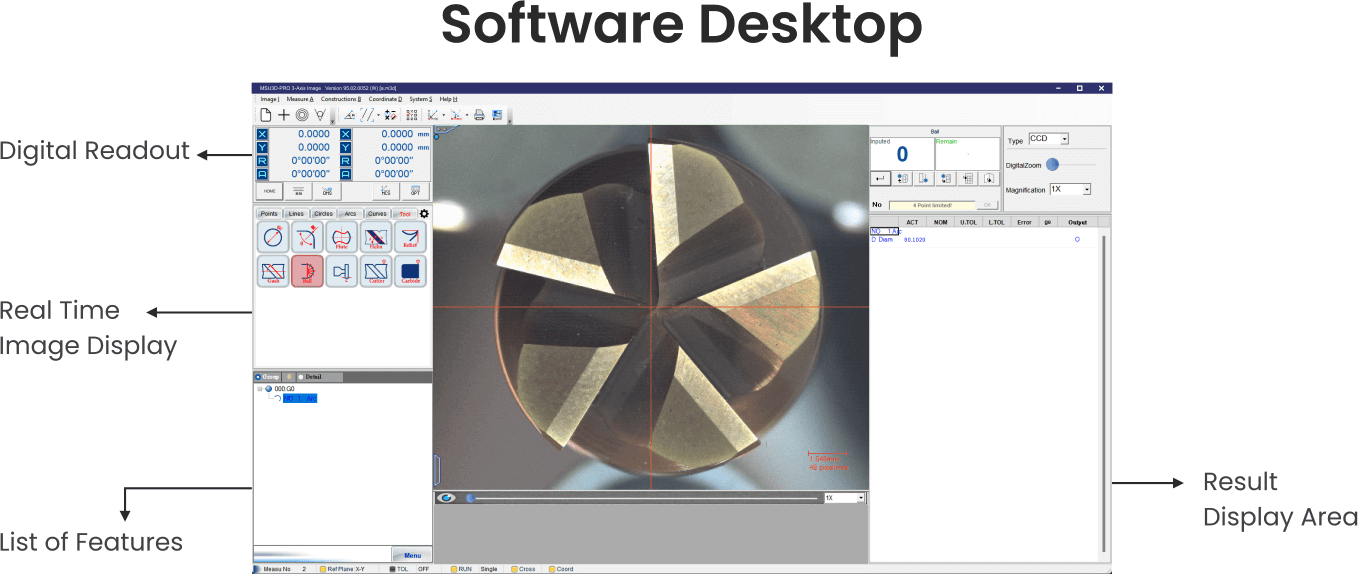

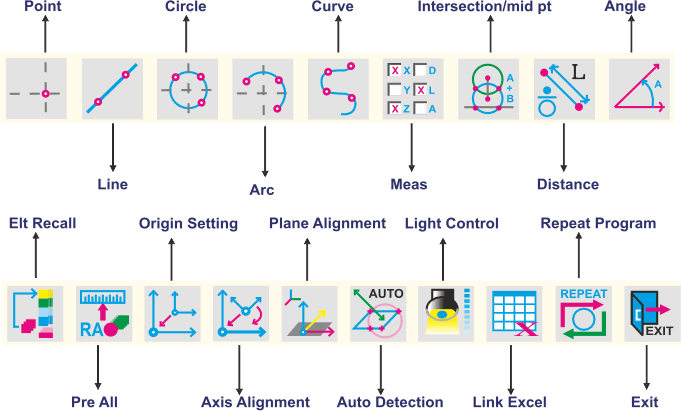

Single-click menu: set measurement origins, align axes, send to excel, and program quickly with ease.

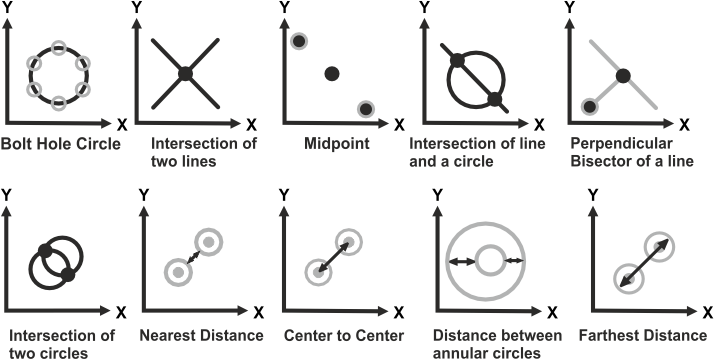

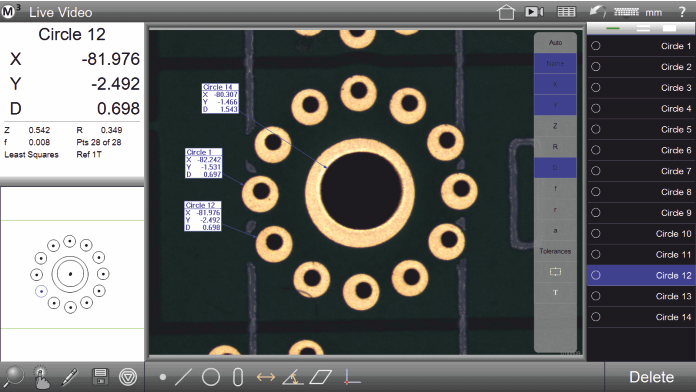

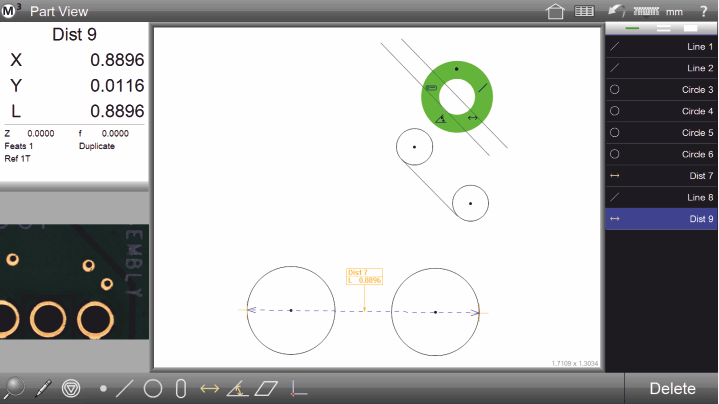

It is easy to create intersections or constructions by selecting multiple features, reducing effort from the operator, and eliminating unnecessary confusion of menus.

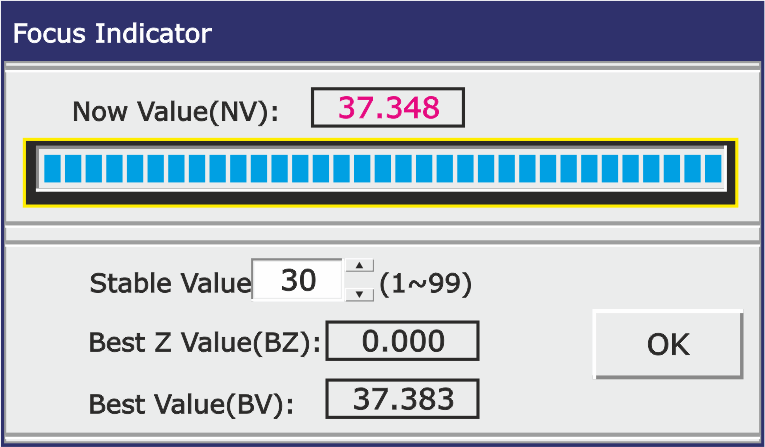

It displays the optimal focus and Z value, while making ensuring optimal focus the part before performing 3D inspection.

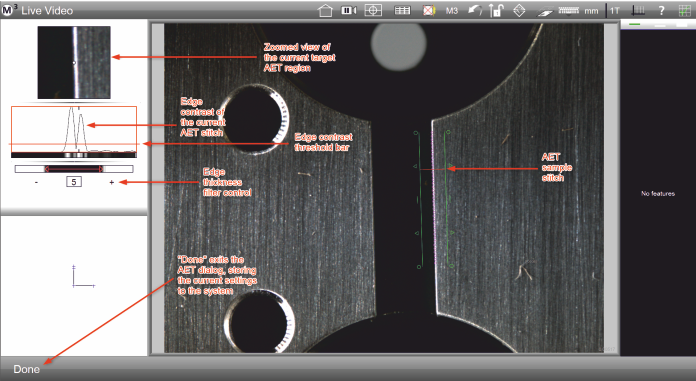

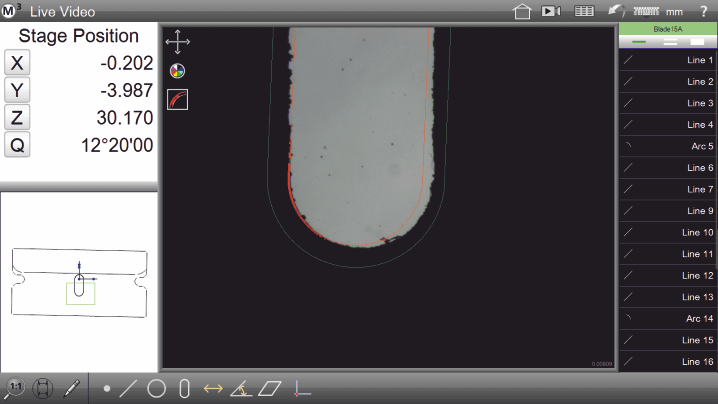

Maximizes feature detection across varying image conditions and illumination, providing uniform the most difficult features to be instantaneously captured.

DXF vector CAD can be applied for side-by-side inspections, allowing immediate evaluation against all tolerances

• Select a data format for easy absorption.

• Incorporate header information, like your company name.

• Include header and footer graphics (logos/page numbering) if desired.

fast to use feature tools in the part view “Gesture Menu” and display personalized data over your live video or part view with only with the selected coefficients displayed

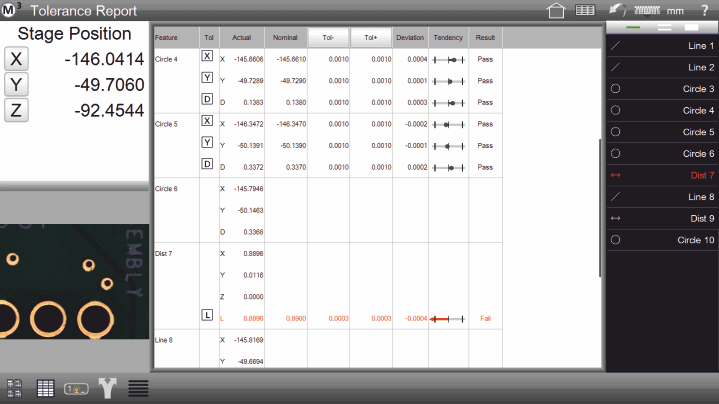

Size : X/Y/Z Positional / Diameter / Radius / Length / Width Size /Theta (Angle) From : Straightness, Roundness, Flatness Orientation : Parallelism, Perpendicularity, Angularity Position : True Position (LMC/MMC Modifiers) Concentricity, Symmetry Runout