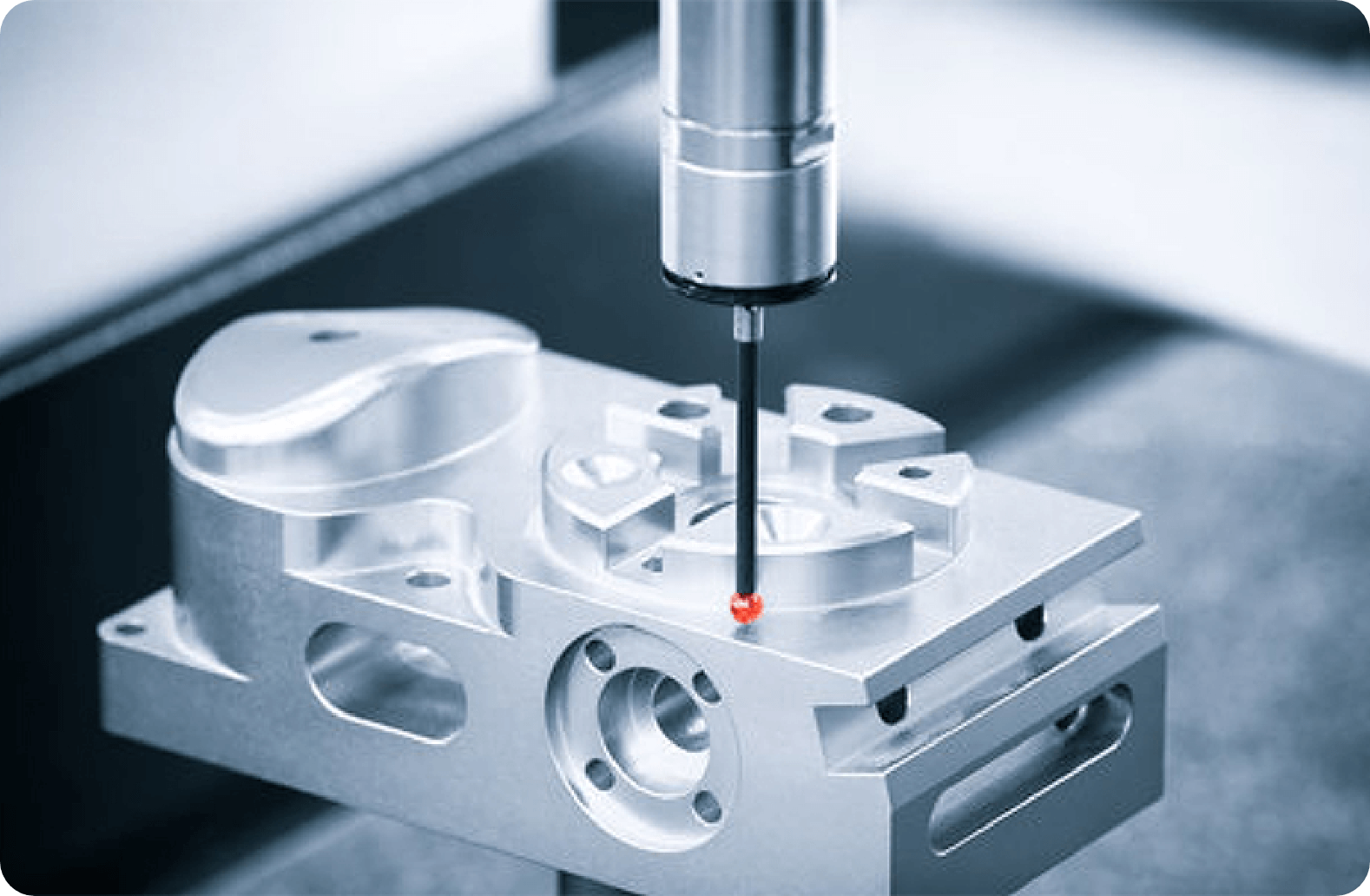

Our Multi-Sensor CNC Inspection System is a breakthrough for quality control in Saudi Arabia industries it combines multiple sensing technologies to achieve accuracy, efficiency, and productivity on system.

Discover the power of Vision, Touch Probe, and more in a single system delivering fast 2D inspection, accurate 3D metrology, and unmatched efficiency for precise measurements every time.

The Rotary Indexer of the CNC Inspection System automatically agree components to allow smooth, multi-angle inspections in the same process for complete accuracy and efficiency.

With a granite base platform, you get unmatched stability, which effectively minimizes vibration and thermal effects during précised measurements

Our approach delivers fast and exact measurements that capture the complete inspection data all in one image to maximize efficiency.

Adjustable intensity is available for each channel via the 4-channel light controller. The settings are stored within the program and are recalled during operation to provide repeatable and accurate illumination.

Simplify Your Workflow with Simple CAD/CAM Printing Export graphs in DXF or IGS format to CAD/CAM for editing, and click the elements in the graph to determine distance between features on the graph.

Overlaying DXF Files to Mag Image Easily compare your part to the DXF file to see if your part is in tolerance instantly.

Best Focus Detection for 3D Measurement This feature will help identify your best focus and the corresponding Z value allowing for clear focus before measuring which is needed for 3D inspection.

Instantly obtain precise thread measurements - easier, faster, and without error.

3D Measuring of Geometric Shapes You measures planes effectively, cones, cylinders, and spheres in 3D space in XY, YZ, and ZX planes only to view the total 3D part annotated with the measuring results, then rotate it to any angle for thorough inspection.

• You can customize all details through our reporting structure:

• Select the data of your choice type Header information you define header information like your company name

Super Image Function for Large Imaging the Super Image function will capture & combine individual frames from the camera, allowing large images to can be viewed and resized within the camera's field of view on both manual and CNC systems.

Improved Edge Detection enhances edge detection performance for a wide variety of images and lighting conditions. Even features that have low contrast or have poor spacing that makes them more difficult to capture can quickly and easily be captured accurately.