Our Vision Measuring System is intended to provide unmatched accuracy, making it is highly suitable for industries where the performance of each micron counts, like automotive, aerospace, and electronics.

Equipped with advanced edge detection, the system ensures highly accurate dimensional analysis. functionality, which can automatically captures edge measurements with micrometre-level accuracy., which allows the operator to avoid manual alignment, providing

Pristine lighting is like nothing you have experienced before. Our system has software-controlled illumination equipped with brightness controls and several viewing modes; it ensures crystal-clear visualization of even the tiniest, most detailed assemblies.

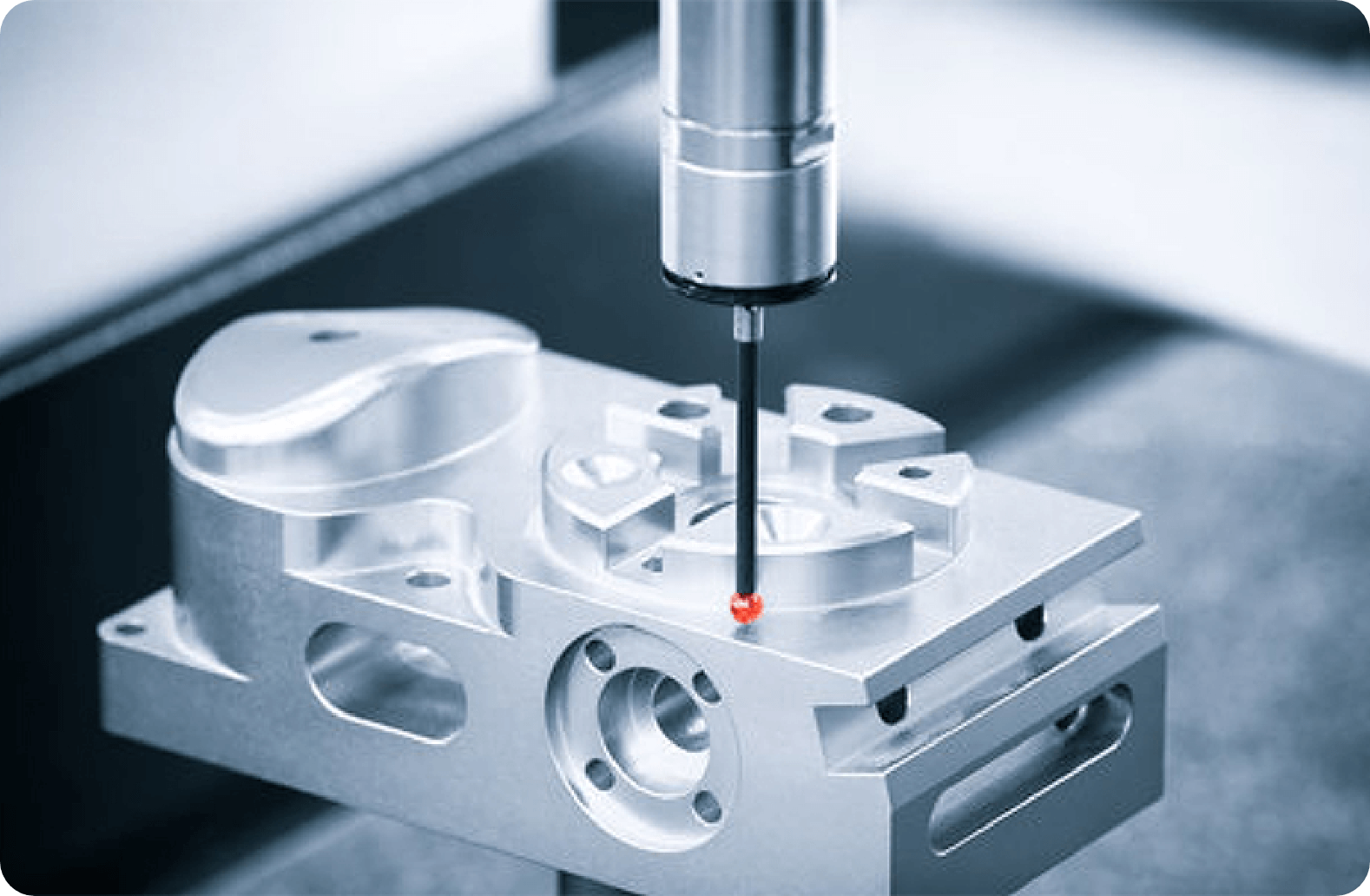

This probe best suited for deep measurement, height, and geometric measurement is designed for parts where depth measurement, height and geometric measurement is perfectly suited for parts.

Measure with precision across angles, curves, and radii in just one pass.

4-Channel Light Controller with programmable channels: Each channels' brightness can be preset, and stored in the program, runs automatically every time the program starts.

Single-click menu bar for all geometric dimensioning define measurement origins, axial alignment, export to MS Excel, and provide programming all from one place.

Select two or more features to produce intersections or constructions in one click, streamlining the process and requiring less work from the operator by not forcing them to work through a complicated series of construction menus.

This feature detects the best focus and the corresponding Z value, ensuring that the focus is ensure a clear view for précised measurement, which is critical for accurate 3D measurement.

Improve the precision of feature detection in lighting and imaging environments. All features, even those with minimal spacing and low contrast, identified using pinpoint accuracy.

CAD overlaid (DXF files) allows for quick comparison Go/No-Go feature and part inspections. A real-time error whisker display is provided, so deviations from the original areas of tolerance are clearly visible.

• Export data in a variety of formats for analysis purposes.

• Add company names of your choice in the report headers.

• Logos and page numbers can be added to report headers and footers.

Access immediate feature tools with the part view "Gesture Menu." Customize feature data to the live video image or part view and display the required specific values.

Flexibility in Measurement Options for Every Part and Components

• Points: Average, Mid/Centre, End, Intersection

• Distances: Shortest, Centre to Centre, Point to Point, Farthest

• Lines: Tangent, Midline, Offset, Skew, Perpendicular/Parallel, Bisector, Gage

• Circles: Bolt Circle, Gage Circle(s), P.C.D.

• Angles: Complementary angles